In Europe you can find good billet foam, or cnc cut, from ATUACORES, their 2lb is now really solid.

Latest…

This one is pretty solid, but a bit on the heavy side. I could probably have shaved off a few pounds, but I was more concerned about the astetics on this on as it’s not mine to keep. I like wood. However I’ve had trouble with water intrusion in balsa, this one paulownia which might be better although I’m a bit skeptical to it’s alleged resistance to decay as the planks I have up on the rafter shows signs of mold growth and that’s from air humidity alone inside my garage. Other woods like cedar is hard to get here and having to resaw and plane the planks to thickness makes it very time consuming. Also the thickness planer I’ve got only goes down to just under 4mm which makes it hard to get the weight down. I really need a way to modify that planer so it goes down to closer to 2mm to make ut useful with heavier locally available woods like sitka spruce. Until then I’m looking for alternative ways to build a strong board.

Easy. Stacking the wood you are planing on top of another piece. Kind of a sandwich thing. With a thicker piece of material underneath the wood you are planing, the piece you’re actually working on can be damn near any thickness you want. You’ll need to attach them together in some fashion so one doesn’t slide on the other. Spot glued with hot melt glue works. Glue at the corners where you will be able to cut loose afterwards. I recommend that the bottom piece be something fairly rigid and have a bit of heft for stability’s sake. Poplar, oak, etc.

Seal up the balsa with thin epoxy so it can’t absorb water its been brought up here quite a few times.

Or what about a simple no external glass build with paulownia skins and rails with an xps core.

A surfboard built with no consequence of damage, will just lead to more shoulder hopping. Lol

I have tried sealing balsa with thinned epoxy, it doesn’t penetrate the entire thickness and thus a ding will be problematic. As for uncovered paulownia, I’m still skeptical as I had mold growth on the planks in my garage. Maybe in a drier climate, maybe saltwater helps though I doubt that there will be any salt left from carrying your board from the surf to the car the way it’s pissing with rain here. Some sort of oil based protection might do the trick though, but it needs to be maintained. Might as well laminate it with something resilient

Lemat, If I understand you correctly, you say that the fabric and epoxy need to be matching in characteristics.

I disagree.

Think about rebar reinforced concrete. The two materials, the concrete (epoxy) and the rebar (fiber) have totally opposite characteristics. One is better in compression, the other in tension. One takes the load that the other is weak at.

In a surfboard skin, the epoxy is only the glue and the waterproofing. The fabric takes tension loads. So as long as the epoxy holds the skin glued to the core. and keeps the water out, it is doing its job. And as long as it is elastic enough so as to not crack when deformed, it keeps the water out.

Fiberglass fails not because of tensile strength, but because it shatters when impacted. glass is brittle, and there is nothing to do about that. Nylon is not brittle, and nylon 6,6 has enough tensile strength to hold together. So when you are reading your load tables, and saying that fiberglass has excellent tensile strength. that is a small part of the whole.

Everysurfer, no problems think what you want you are certainly ok.

I only say what applied in industry for 10 years and learn to my students. I learn it in university, from one of master material doctor specialized in composit. All is demonstrate in material engineering book. The simplized equation I use before demonstrate what I say : matrix must have higher elongation to break and lower young modulus than fiber I you want fiber play reinforcement role. You need to choose resin to go with fiber properties.

May be my English is to bad to well explain it, sorry.

guys ya missing one big factor? there only surfboards i have dispiesed the egg shell glassing since the eightys 4 oz free laps sanded finish all shit and by rights should have been dead and burried long ago. but anything away from this is ten yrs ahead of the sheep and mindless surf culture media

the bit of carbon s glass stiched is creeping inn but most will prefer a white glass job wacked out in the same old sorry routine

i only build limeted numbers these days and all are bomb proof and those that have them are apreciative.

**in my oppinion the polyester days are numbered at best left to china. **

**the newer epoxys have let me achieve a board that i no longer need to sand **

**and vacum is a major tool **

for you guys making just a few and want a board with a good memory flex light and strong as you just need to work it out with the material as you want it

spend more time making the board do not put a time factor on it when i do the infused veener boards i go under vacum 3 times so thats 3 day just to shell it

but the bonus is a board as light as most poly e glass crap and ten times stronger

and yes i match the wood to nylon, when i used to use e glass it stiffened the skin. but the nylon its alive and the epoxy is a more flexable resin

so its all good ya just gota chose which is best for you and stay with it

and do not pick me up on spelling or i might get pissed

cheers huie

OH YES !!!

My answer to the original question:

XPS with normal glass/epoxy

Hi Chris,

The biggest downside of a XPS/ regular glass/ epoxy board is the really weak mechanical bond between EPS foam and the Epoxy cloth. Do a test. Laminate a small patch on some scrap. Then peel it off. It is almost like the foam has a release agent on it. So even if you don’t see it, the shell will shear away from the foam. You can go the fletcher chouinard way, and do an extra thick skin, to stiffen the skin, so the delams won’t wrinkle that much. FC boards have so much cloth on them that they are heavier than a lightweight PU 4x4x4 resin board. And that is with a XPS core. Or the 3d method where you are “nailing” the skin down with the perforations into the foam. But you can’t get past the poor bond of materials.

But even if you go the XPS way. Nylons will still work better than fiberglass.

my “experience” is limited to one board. Which I love.

I was being kinda tongue in cheek with my comment.

For sure, it’s not the stronges build out there. And really not the most ding resistant that I’ve even done.

BUT, who cares if I get a ding? Don’t even have to get out of the water and, the board RIDES GREAT!

Cheap, easy, and worry free… I’m sold… Now if I could just get some more.

I just want to interject because this is a good discussion and I want to make sure everyone’s on the same page.

Everysurfer, forgive me if I’m wrong, but I think you might be slightly misunderstanding Lemat’s point about the materials “matching”.

Lemat, correct me if I’m wrong, but my layman’s understanding of composites is that you want to match the modulus of elasticity in proportion to each other. If my memory serves me, the reinforcement generally should have a modulus around 4 to 6 times greater than that of the more flexible matrix(?). This is why higher-modulus reinforcements like S-glass or carbon are combined with higher-modulus resins. Or conversely, a reinforcement with high elongation (and hopefully elasticity) like nylon or polyester, would need a matrix with proportionally-higher elongation and elasticity. This would have to be a very flexible - or as you said: “elastomeric” - matrix.

Am I correct in my explanation?

For me yes if you want to used the best of reinforcement fiber, you take care to make the composit work in tensil. This is where begin problems with sandwich in flexion, because one face need to work in compression where composite design for tensil are not good.

Hi Newschool,

I’ll leave Lemats explanation for him to clarify. Probably some gets lost in translation.

My take on it is that the glue and the fiber don’t matter to each other. This is because the elasticity will be limited by the less elastic. If the glue is elastic or inelastic, the amount of strech will be limited by the less elastic fiber.

The failure would be if the fiber is more elastic than the epoxy. If this were the case, then the strength of the fiber would never come into play. If you glassed with epoxy and rubberbands, you might as well as leave the rubberbands out.

This does not mean that the epoxy elasticity doesn’t matter. The epoxy is the glue that holds down the cloth to the core. If the glue bond is too inelastic, you will get shear failure from the foam to the skin. If the epoxy is too elastic, then it will be hard to sand and finish.

Consider using different resins for different steps in the lamination. A more elastic epoxy to bond the cloth to the very elastic foam. Then finish with a less elastic/ harder resin to be able to polish.

And back to the original thread theme. Glass cloth shatters, so it dings. Nylon 6,6 doesn’t shatter, to it dings less. That is proven in the real world. Huie, Coil and myself use nylons (among other fibers) for glassing. Speaking for myself and my boards, a store bought 4x4x4 board gets pretty trashed in about six months. My Nylon builds last ding free for years.

Ding proof ???

I make a little bit of money on the side doing ding repair…My next new board and my new Front Zip 4-3 wetsuit were paid for with ding repair. So maybe dings are a good thing???

I’m happy to fix dings…I think light weight cores and light glass jobs cause dings…and Cavemen…and surf mags…and ultra light surfboards…

I’ve never had a ding problem with my personal boards…EPS and Poly…most glassed with 6 bottom and 6-4 top…

some people don’t know how to take care of their equipment…so they pay me to fix their stuff…

A better foam core is cheaper than High Tech fabric…and vac bag…but you have to be a good glasser to get the job done…break away from the pack…feels good.

Stingray

Used a lot of Xynole which is quite tough. Use it with a glass cap. Use a more flexible resin (2020) and it’s tough to ding. Nice white finish too.

That’s what lemat have been saying all along. In effect, the nylon is the rubber bands as the nylon is more elastic (lower young’s modulus) than epoxy. Since the epoxy is less elastic and breaks before the nylon (lower elongation to break %), the epoxy will fail before the nylon “rubber bands” will take any load. When the epoxy fails though, the nylon will still be intact and start taking up some load.

Does anyone know some good sources/tables with specs for different types of glass and synthethic fibers?

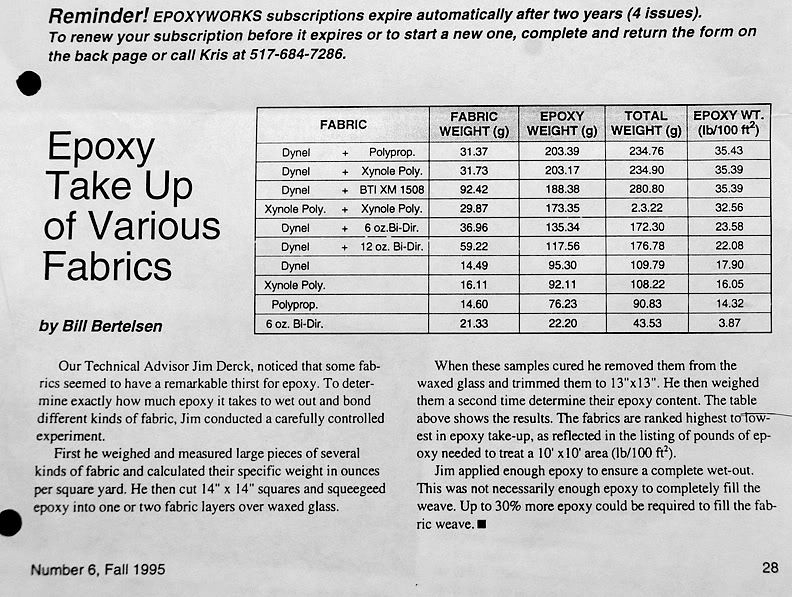

While looking for info on xynole I cam across this test, an impact test over wood for protecting a boat deck:

![]()

Looks like a combo of Dynel and polypropylene is pretty good? But you have to read the small print too:

So the dynel + polypropylene + epoxy is so resin rich it weight more than five times as much as a layer of 6oz + epoxy. So while it may be an adequate way to solve the problem at hand, it doesn’t really tell us which is stronger for it’s weight and leaves me wondering how five layers of 6oz would hold up compared to dynel+polypropylene.