Shot Robbo

I’ll see what I can find. You won’t believe how difficult it is to find stainless steel nuts and bolts in SA. It’s f-ing crazy!

Seems things don’t rust down here. Somebody should have told my Toyota though!

Cheers

Antman

Shot Robbo

I’ll see what I can find. You won’t believe how difficult it is to find stainless steel nuts and bolts in SA. It’s f-ing crazy!

Seems things don’t rust down here. Somebody should have told my Toyota though!

Cheers

Antman

Thanks Pat

I’m constantly amazed at the willingness of guys on this site to help others. It’s great!

Antman

hey antman

I Used a cheapish alloy tee nut from loacl hardware shop set in epoxy in an oversized hole drilled thru my tail block. Nice and out of the way. You could use brass or monel (sp) bolt or something along those lines.

cheers

Quote:The vent on mine looks exactly the same, only I just glued a couple of extra blokes either side of the stringger

Yikes !!!

Don’t worry Roy I didn’t drill all the way through the board ; ) only to the webbing, the blocks were ½” deep 1” long and 10mm thick either side of a 5mm stringer, the thread on the screw was 4mm.

It works fine and gets a good seal, get the hiss of air escaping when its un screwed. No problems with it so far.

Quote:The vent on mine looks exactly the same, only I just glued a couple of extra blokes either side of the stringger

Yikes !!! :)</blockquote></div>Wonder… did he use PU glue or just good ol’ wood glue…

Musthave tightend the bar clamps good to keep from escaping…

Bet they help with straight line speed though…

Missing any relatives Roy?

LOL!!

As chip would say…

PICTURES!!!

Quote:Quote:The vent on mine looks exactly the same, only I just glued a couple of extra blokes either side of the stringger

Wonder… did he use PU glue or just good ol’ wood glue…

Musthave tightend the bar clamps good to keep from escaping…

Bet they help with straight line speed though…

As chip would say…

PICTURES!!!

simple …router out a coupla spaces either side of the stringer , and glass THESE blokes in there [shown actual size] …

Now I get it!! The typo gremlins strike again.

Seriously mate, the 15 minutes it will take you to install some sort of vent will be time well spent. The effort put in so far looks like it deserves this. I live in England and surf mainly in the colder months, every time I open my vent after a session the board hisses and creaks (yes, in cold sessions). My first board, even with a vent after a session in the summer now sounds like the frame has come away from the skins in places, as I forgot to open the vent when I drove off.

The way you built this looks an interesting alternative to the usual (if there is such a thing as a usual HWS method).

Please, please, please install a vent. I hope there is also enough airflow through your joints in the frame and skins.

Kracking work so far.

Hey TBS78,

Put a vent plug in…

The End…

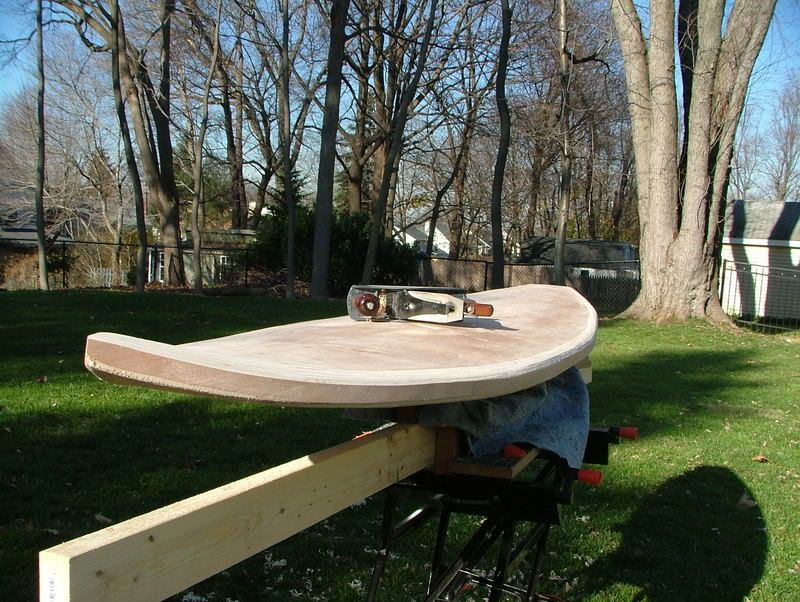

Finally some more progress. I just about have the rail strips on, can’t wait to take em down with my hand planer. I guess you guys have convinced me to put in a vent. The board is up to 18lbs, feels like lead compared to my CI epoxy flyer.

http://new.photos.yahoo.com/rbccmsst/photo/294928803574652786/5

http://new.photos.yahoo.com/rbccmsst/photo/294928803574672469/8

http://new.photos.yahoo.com/rbccmsst/photo/294928803574735480/10

“Kracking work so far.”

so you poms really DO say that eh ?

EXCELLLLENTTTTT !!!

…I always thought that just existed in Nick’s world ?!

[…"CRACKING toaassst , Gromit ! "…]

I’m going to have to take Chip’s word for this being excelentttttt as I can’t open your pics, which is a shame cos I really want to see this…please post pics as norm, please!

Ahhh… the smell of burning wood wafting from the sander…

Looking good mate, are you adding any more to the rails?

i have since attached another strip to the rails(.25in) since that pic. the burn marks are from the flush-cut router bit. i tried to trim two strips at once and got jammed up. actually burnt up a bearing on the bit, set off the smoke alarm, big mess. i think the rails are thich enough now to shape up nicely. i think they will be boxy, though as i went way too thick with the board. next one will be better. thanks for posting the pic, what’s the trick? i tried using a link to yahoo pics, but didn’t work.

it almost time for me to start asking about glass-on fins vs. fin box. i plan to make it a single fin.

I am getting ready to install the vent, or at least drill the hole, but I am concerned about drilling through the deck, there is lots of tension on the .25in plywood, because of the dome. I am afraid if I drill a hole the whole thing will start to split. Any ideas?

Put 3 or 4 layers of masking tape over the area you are going to drill, it won’t split that way…

Have the vent ready to install and just peel the tape off and glue it in straight away…

How about you install your vent aftere you do your Laminating? Aloha Wood_Ogre

thanks for the suggestions on the plug install. nice weather today and the kiddies took a long tap so i finally got a chance to start taking down the rails.

hey look i figured out the pic posting…

will post a few more tomorrow, rails nearly done, but no pics yet