My cousin got one of Bert’s boards about a year before I got one , when I got mine it had a vent , my cousin’s didn’t .

Bert explained the vent was to let the pressure out of the foam when it got hot .

The next summer , Al’s board went all soft under the back foot and blew up like a baloon one day in his car , Bert put a vent in it and rebuilt the tail area , that was over a decade ago and he hasn’t had a problem since .

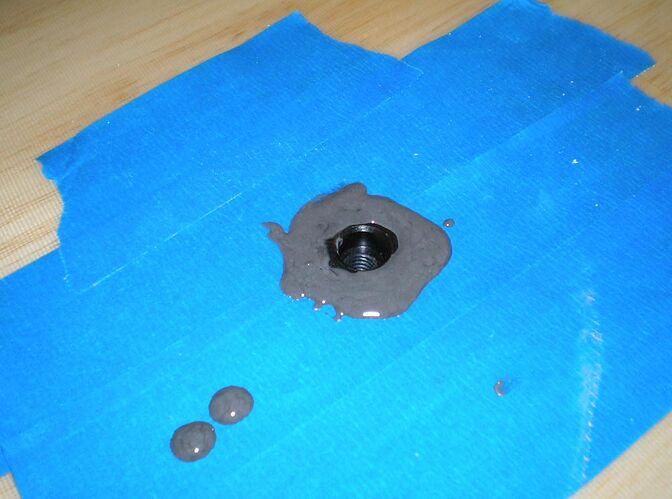

I’ve never had any dramas with mine , but my first one has a different type of vent , when you undo it after a surf it makes a noise like cracking a can of coke , so it’s obvious there is some pressure in there .

I was told to use my vent religiously , Bert explained something that sounded a lot like what Jjp said .

I also left my vent open once and got a stain around it and on the bottom of my board directly underneath the vent , it took about 18 months to dry out and for the stain to go away , I could have got it fixed , Bert said he could have drilled a few holes and blew it out with air , but I never bothered and it went away by itself in the long run .

Matt