I’d love a turbo for my Skill 100!! Put me down for one if he is willing to make a few more. Many thanks.

wow lots of aloha here’

i would also love to get a turbocharger

wow lots of aloha here’

i would also love to get a turbocharger

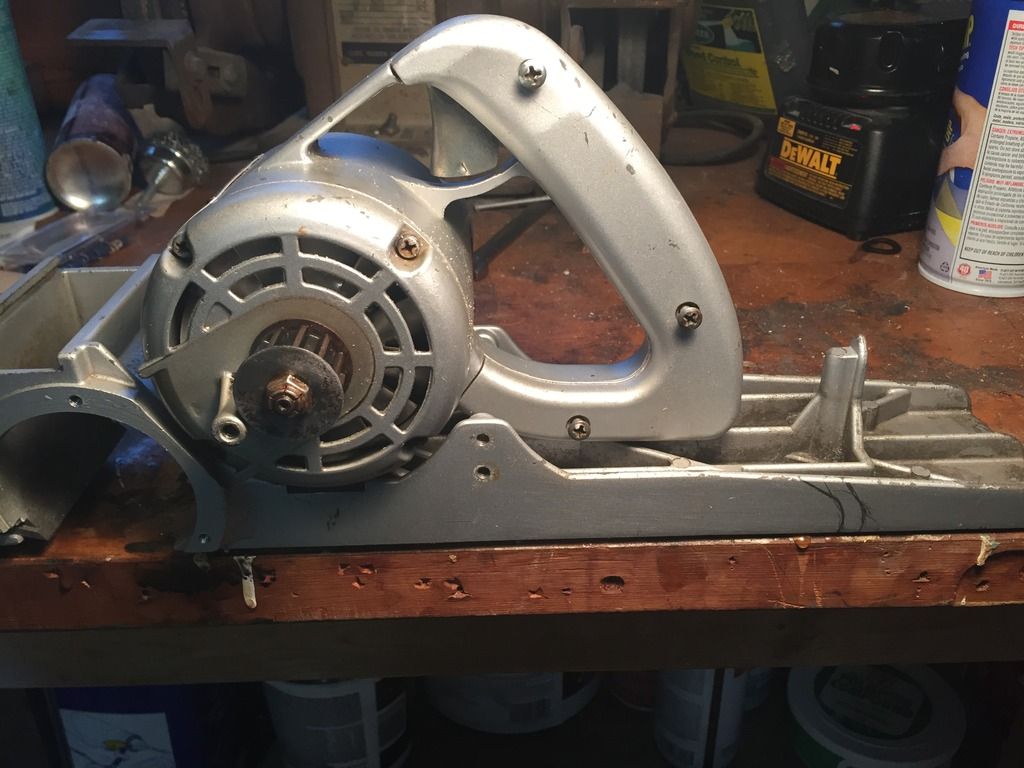

Back to tinkering on this project. The remainder of the parts needed to complete this project should arrive tomorrow. This afternoon I set out to shorten the base.

After looking at a lot of pictures of Skil 100s I decided to cut the base at the cord stand off that is molded into the casting of the base. Measure twice…cut once.

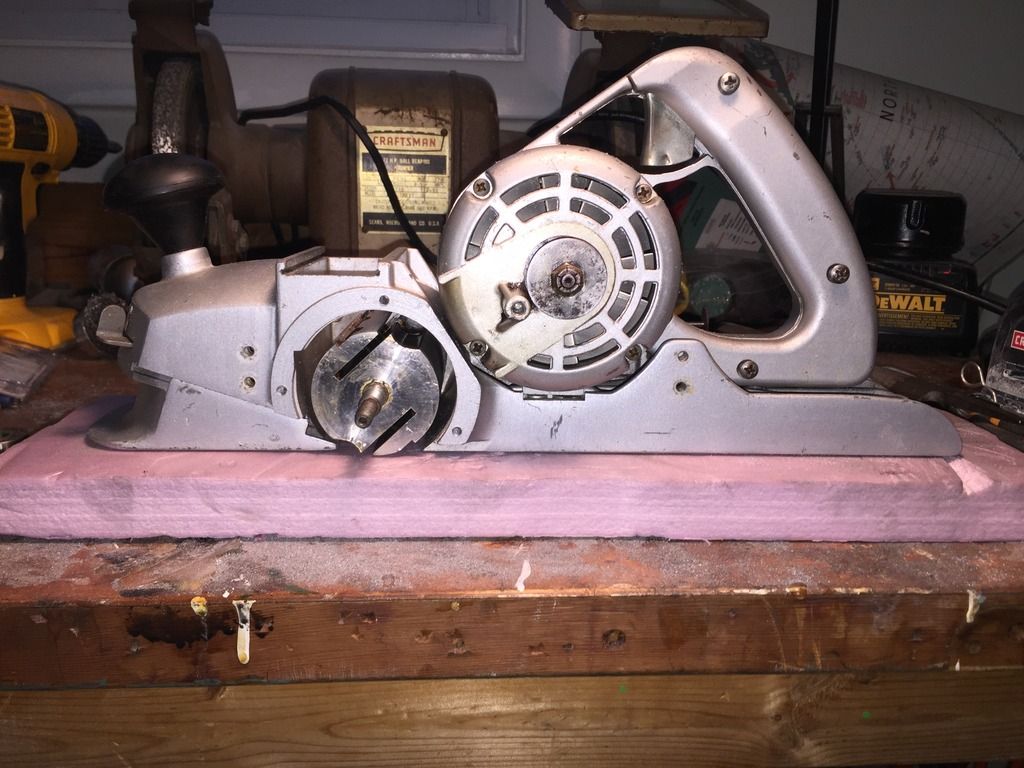

Next I took the off-cut and traced the radius onto the base then it was off to the bench grinder to take it down about to the line.

Next I used a sharp flat file to complete the radius. Then I used a stirring stick to create a template to create a pleasing arc to the tail end of the base. I used a dremel with a cutting wheel to cut the corners of the base and the fins inside close to the line and then used the flat file to finish shaping the tail of the base. Next I got out the palm sander with some 120 grit sand paper and cleaned up the bottom of the base. I also eased all of the edges on the base ever so slightly. The factory edges on these planers are very sharp corners and I wanted them eased ever so slightly so the planer slides easily over the foam without catching an edge.

Next I moved to the shoe. I used the bench grinder and flat file to round off the leading edge of the shoe to a slightly more rounded shape. Nothing too drastic here. I increased the radius on the corner perhaps an 1/8th of an inch. I shaped everything with the flat file so it looks like it was done at the factory then cleaned everything up and eased the edges slightly with the palm sander. In the first picture you can see I’ve rounded one corner.

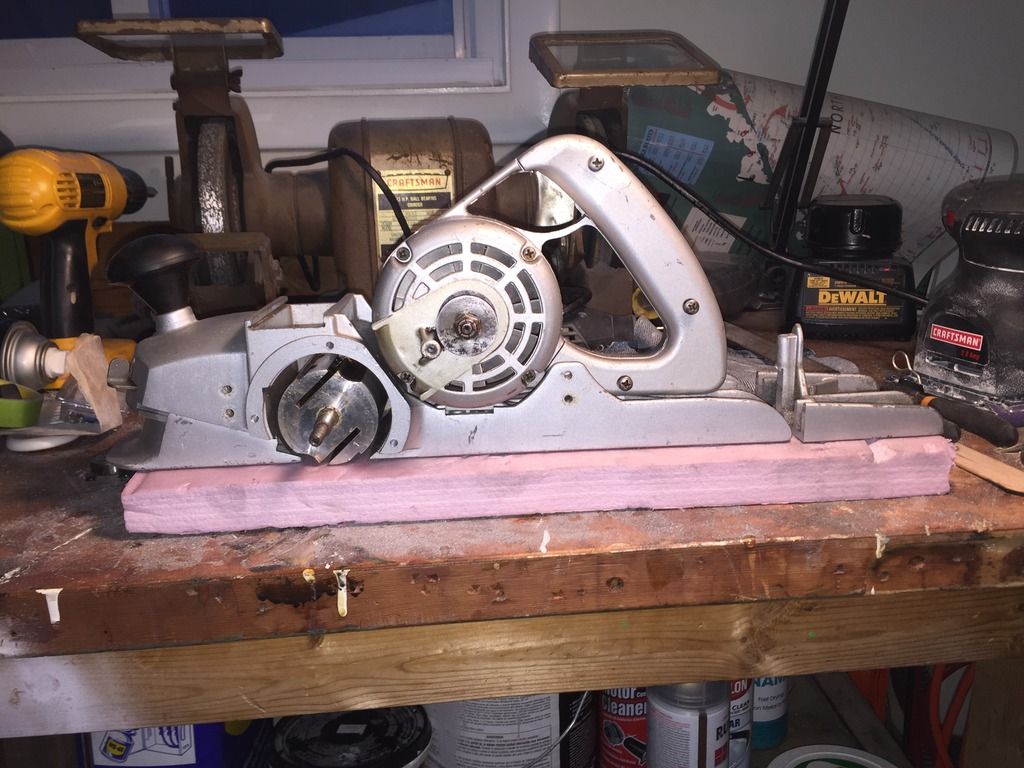

Then I put it back together for a mock up and snapped some pictures. Enjoy.

Here is a shot of the collection. Once I wrap this project up the Rockwell and possibly the Hitachi will go on eBay. If you’re not careful they begin multiplying like surfboards. This picture gives a good comparison of the stock base on my Type 4 and the now shortened Type 5.

Is it on backwards, or just there for the photo?

Its just sitting on there for the photo. No screws.

My compliments to the chef. I really like the curve on the rear of the base plate. I haven’t mustered up the courage to take a saw or file to mine.

Thanks. Cutting the base was a fairly easy project if you have the tools. Tonight I got the base reassembled with new bearings. Tomorrow I will do the bearings and brushes in the motor and get it all back together.

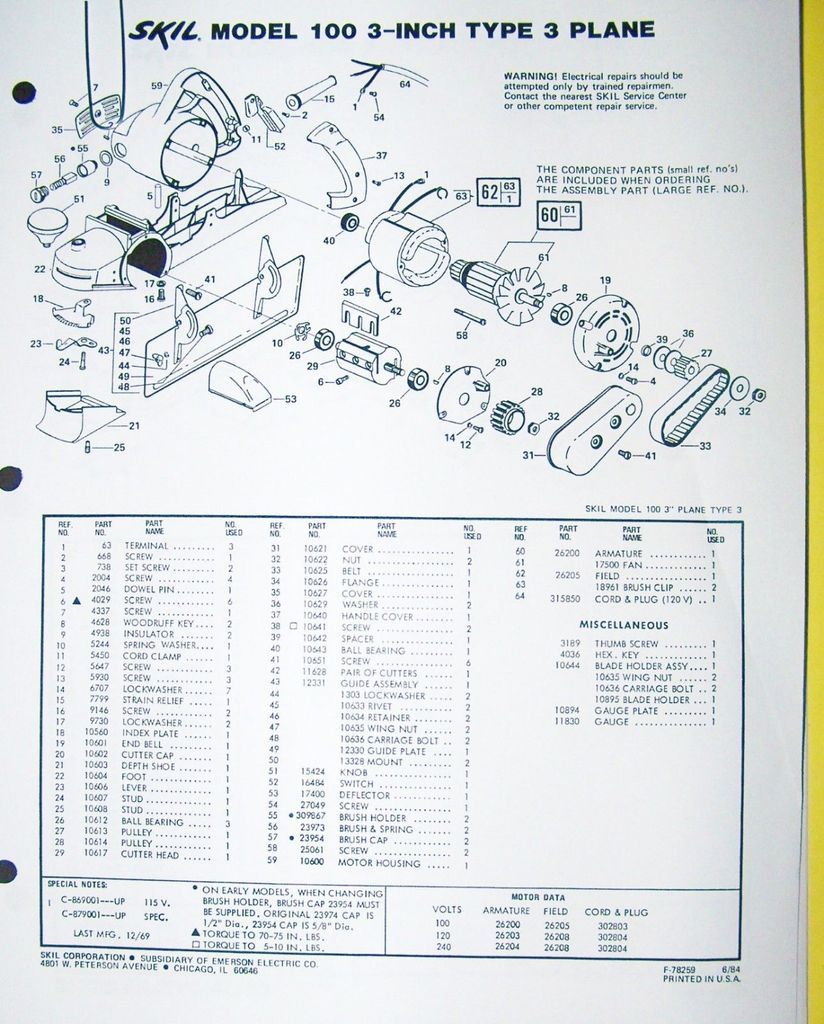

Going to throw this up here since I finally found a legible copy of the parts diagram on the web. I’ll also throw out this link for a supplier for the finger spring washer that goes behind the cutter bearing: https://www.springmasters.com/sp/finger-spring-washers.html

Got it all back together. After doing the belt, bearings and brushes sharpening and installing blades I wanted to hear it run. Sounds fantastic. Still need to make up a new power cord.

Impressive. Come shape a few for me.

All the best

I spoke to Charlie today. He has 2 turbo chutes for $40 each. Let me know where you are and I’ll try to get them to you. I think mailing it is around $16.

Dennis

I will take one. I’ll shoot you an email to make arrangements.

I am picking up two turbo chutes tonight from Charlie. One is spoken for already and will be mailed out tomorrow. One is still available. He can make more if there is an interest. Contact me at dvarde@hawaiiantel.net if interested. They go for $40 each and shipping is between $15 and $20. I think similar ones sell for $60 each at Fiberglass Hawaii. I should get the shipping price firmed down when I go to the post office. Thanks, Dennis

Thank you Dennis. Much appreciated!!!

Just want to thank Dennis again for his aloha that has helped a guy almost 5,000 miles away to get this Skil 100 back mowing foam. All that is left to do is make up a new power cord.

The Turbo Chute fits perfectly. Hats off to the guy who took the time to design it.

Thanks for the pics Mako!

That chute makes that thing look fast just sitting there…

Dammit, now I want one!

That chute looks awesome on that planer. I better tell Charlie to make more. Those last two went pretty fast!