Thanks, that's a good idea to get the racks set before the lights. I've been using the same 4x4 in wobbly buckets racks for years, always with the thought that I'd get some nicer ones made someday. Never had a problem with the height until I went into a buddy's shaping room and saw how low his racks are relative to my own... got me questioning if I've been making things harder on myself all this time. Is there like a bellybutton rule of thumb or something? Adjustable height would definitely be the best, but I'm trying to keep it easy for my welder friend who is doing me a big favor. :)

Shwuz,

Couple of things…firstly, congrats on building your own space…

You mentioned sheetrocking - don’t know where you’re located but, if heat retention isn’t a big deal, don’t bother rocking the side walls - saves an inch where every one counts - plus, the end walls is where the sight line counts (rock & paint those) & makes mounting lights & shelves easy. If anything, also, use particle/fiber board (some yards call it different - same as backing on bulletin boards) - makes pinning stuff to wall easy and only needed above light shelves. Look in the archives for light heights - Jim Phillips posted some numbers and I ended up raising my lights and it helped alot. Mine are now 10 to 14" above racks.

Also, don’t cheap out on lights… 4 ft. each side is inadequate. IMO lights should be at least as long as the board being shaped - or, at least two 4’ long ea. side… $9 +/- for 2 light 4’ @ Home Depot. Buy the bulbs in box of 10 or 12 there too.

Noticed you framed what looks like a fan opening on the left wall. That should be for air intake and mount your exhaust fan down low on an end wall at opposite end from intake since dust and, if you’re going to glass in there too, resin fumes are heavier than air and will be sucked out better - again, IMHO.

The setting up of your own board building space seems to make everything come out just that much better. Have fun with it all -

Pete

Sweet, thanks for the input, Pete! And thanks for the congrats, it has been a long time coming… Don’t know if anyone remembers, but my first few boards were shaped and glassed in a tiny porch at an apartment. My two car garage a few years ago was a huge leap forwards, but I’m seriously finding the limits of that with regards to lighting and dust control. I’m thinking that the garage will be exclusively glassing/vacuum bagging space now. Funniest thing, I’m still using the same shaping racks! I’m WAY overdue for new racks!

Lets see… Heat retention isn’t really an issue, but cool retention might be. I’m in south texas, so in the summer that thing will probably be a real oven. The framed in square there (good eye, by the way), is for a 5000 btu window AC unit. It’ll probably be enough to make it comfortable. Barely. ![]()

I was only planning on rocking and painting the side walls below the lights, but I totally see what you’re saying about that not being a primary sight line… Good call, might be a real time and frustration saver (I’m not much of a rock-hanger) to just do the end wall.

Lights are two 4-ft fixtures on each side, plus two overhead for templating and general use. If I had just a leeetle more interior length I’d go three 4ft fixtures on each side… Actually thinking about getting a couple of 2-ft extensions to just kind of fill the gap a bit. So, if I’m using two 4-ft fixtures on each side, should I butt them right up against each other, or space them out a little to cover more overall length?

I have searched the archives for light heights and shaping stand/rack heights, but this new search feature is a little confounding to me so far. I’m apparently not using the right search terms, because I’m not getting the results I need. So any hints in the direction of “rule of thumb” rack and light heights would be most appreciated.

Thanks again for the input! I know it will always be a work in progress, but I’m hoping to get this “mostly right” right off the bat.

I’m going to go ahead and throw this out there…

The minimum is 5 ft wide for short boards…discuss.

This is partly due to this being as much room as i have been allocated in my new garage from my wife…i think it’s doable…i’m a little guy anyway. Just gotta keep it clean and organized and i think it’s doable…maybe put my shelves at the ends of the two shorter walls as opposed to above the lights.

Shwuz,

Go to www.swaylocks.com/resources/detail-page.cgi?ID=470&d=1

It’s in the resources under “More Shaping Hints from Swaylocks (Vol. 3)” under “Other tips for a good shaping room?” circa 2003.

And yes - butt the lights end to end and, if you can fit it, I would add the 2 footers - can’t hurt…

Just tried clicking on the above link and it didn’t work??? But, type - “shaping hints from swaylocks (vol. 3)” in the search bar and it gets you there…good luck

Air conditioner a MUST for me, since my days in HI. Even though my room now is about 100’ from our cool ocean here in Ventura, body heat alone can make a cold room uncomfortably warm in no time. So it is good you’ve planned for that in So. Texas. IMHO, you should cover ALL wall space inside the room for 3 really good reasons:

(1) Noise control–you don’t want to piss off your neighbors. Get “soundboard” from the local builing supply–it accepts tacks and will help insulate as well.

(2) Insulation (see above)–it’s not just for cold climates–especially since presumably your air-conditioned space will not be the same temp as the outside air.

(3) Dust control. Less foam will leak to the outside and clean-up will be a lot easier.

I don’t think any useful space is to be gained anyway by leaving the space open between studs, and soundboard is only 5/8" thick anyway. BTW, previous to my current room, I felt 9’x16’ to be the ideal room size. I had more width available to me this time, so rather than bring walls inward to make the lights hang an ideal distance apart, I built two deep cabinets, one on each wall, then hung the lights on them. The added storage space (mostly out of the dust) has been great. Also, having the wall racks farther from my head and sightlines has added another level of comfort. Just an idea if you need to relocate and ever have the space to do it.

Keep up the good work!

Chuck

Cool, loving the info here. Good tip on the resource thread too!

Well, I think I’ll have to insulate after all. What a pain. ![]() I got the AC installed today, and it’s definitely not going to be up to the task as it is. Its only 87 degrees today, and the shed is barely any cooler inside than outside. The AC says it’s rated for 150 square feet, my shed is only about 85-90 sq/ft… Definitely not doing the trick though. Any ideas on that?

I got the AC installed today, and it’s definitely not going to be up to the task as it is. Its only 87 degrees today, and the shed is barely any cooler inside than outside. The AC says it’s rated for 150 square feet, my shed is only about 85-90 sq/ft… Definitely not doing the trick though. Any ideas on that?

I use soundboard not just for sound but also the insulation properties.

R19 installation in the walls + soundboard + 1/2 drywall = Home Cheapo (Home Depot) as what you need. Mud your walls smooth then paint it a color you like that will give you a nice contrast while eyeing your finish work.

The A/C should work better. However I never have had any luck with the wall mounted type units regardless of there rating. The foam dust just kills them. The good lord willing and the creek don’t rise I will install a 1 ton unit and inject air in too my room by this summer. I’m in California so we only need it for about 4 months. The problem is that’s when were slammed. Any warmer than 78 degrees and the fun goes right out of it! You may have better luck with your unit?

Yeah, I just went and picked up enough r19 to do the job… There goes $166 I hadn’t planned on. ![]() Oh well, better to do it right than do it twice.

Oh well, better to do it right than do it twice.

I know I really should rock the walls… Can I tell you how much I hate drywalling though? It would look way better in the end, I know, and I’d be glad I did it… But ugh, taping and mudding and sanding. No fun.

The reward is more than worth it!

I used 7/16 osb instead of rock on my walls…it was 1$ less per sheet.

For an exposed structure with 5000 btu, you need to insulate the crap out of that thing and drywall and tape and seal until it’s as airtight as possible.

For an exposed structure with 5000

btu, you need to insulate the crap out of that thing and drywall and

tape and seal until it’s as airtight as possible.

<div class="forum-post-footer clear-block">

Absolutely!</div>

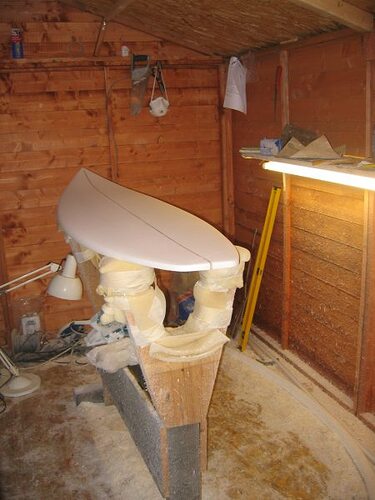

Progress.

All I’m lacking now is my side lights, shelves, racks, and shaping sands.

Oh, and since I put in the insulation and sheetrock the difference in temp in there is absolutely STAGGERING! EVen when the AC isn’t on, it’s noticeably cooler than the outside air temp even in the heat of the day. Good call on that, even if it was a pain in the ass to install and more cash than I wanted to drop.

Hey Jarrod,

Nice dolls house mate! You can definitely play with your My Little Pony’s in there…

It kinda scares me what your gunna produce now with some sweet dedicated space…

About August you’ll be REALLY glad you insulated and drywalled. Were they having a sale on fancy pre-hung doors? That’s WAY too nice of a door for a shaping room (need to paint it blue on inside, btw). Then you need a sign or something over the door to commemorate the building…

Memo from your wife, “Honey, now that the building’s done, will you please mow the damn lawn!”

Nice job Shwuz.

Pete

Damn, have you guys been watching over the fence? If so, we need to talk about not pitching in and helping. ![]()

In fact Pete, I already have gotten that memo from my wife… I tried to explain that all the increased traffic will naturally kill the grass, but she’s not having it. The other thing from her is, “Now will you work on my boat?”.

And yes, they were having a sale on fancy pre-hung doors! Actually, this one was damaged in shipping (paint scratched), so I picked it up for less than $100. Lucky, too, since out-swing 36" doors are kind of hard to come by. I wanted a good one so I could lock it up and not worry about keeping my tools in there.

my glssing room and shaping room, is till dificultt to work but with the time you have practice,,,

the room is separated with a plywood wall in the middle of the room, so , when you finish to work, you move the wall and then you have a necesary space to glass...

before this i was shaping in a tent,,,,so this is the best now...

In summer (it gets to 40-45 degrees C (110 F) on odd days - a week straight last summer) I rig shade cloth over the roof and sun-facing wall. It seems to stop them getting up to a zillion degrees and radiating heat inwards. Can always plant a veggie patch next to the shed and claim the shade cloth is protecting the plants!