@ Lemat – I do not have the time or equipment/money for 4-point bending tests. I believe that low density/low min. compressive strength XPS foam tests should give me some usable information about adhesion between epoxy and XPS.

@ Dr. Strange – I peeled several PU/PE longboards in the past. I was surprised how little foam was pulled up. I still had plenty of good foam to work with. Funny you should mention EPS, I have been planning to play with Secret Sauce on it too – different reasons.

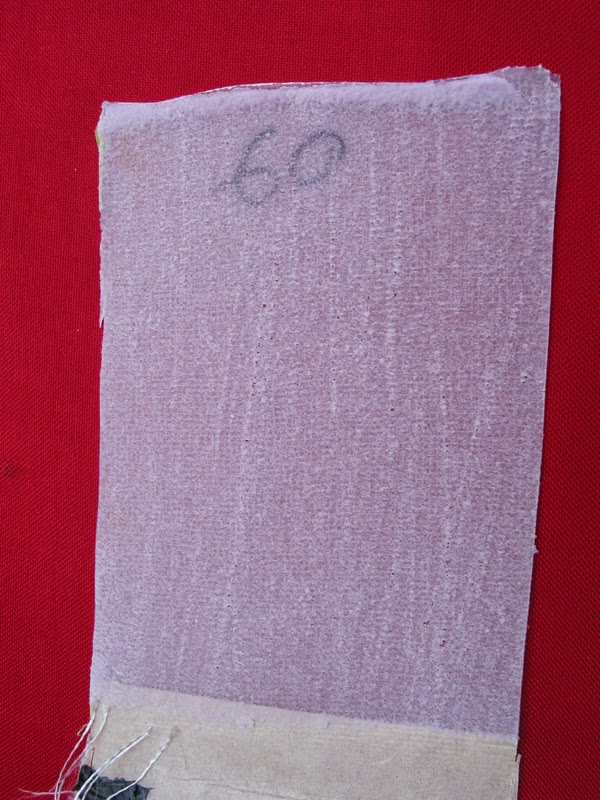

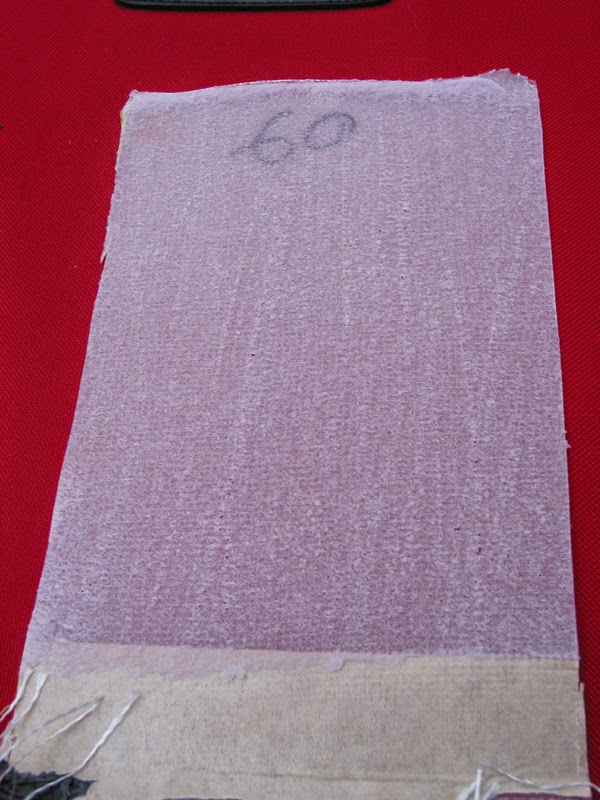

@ Barry Snyder -- No surprises. The greater irregular bonding surface created with coarse sandpaper caused more foam to pull up than with higher grit surfaces -- better anchoring. Yeah, I really want to try the perforation rollers next.

@ John Mellor -- Agreed. Sealed vs. unsealed was/is the central objective of the tests. The initial hypothesis was/is sealer will improve epoxy adhesion with XPS. The null hypothesis is sealer will not improve epoxy adhesion with XPS.

For the first test, I was more interested in seeing whether the polycrylic sealer would bond with XPS and whether epoxy would bond well enough with the sealer. The results suggest epoxy adhesion with sealer is stronger than sealer adhesion with XPS. Side-by-side sealed vs. unsealed is definitely needed. I decided that looking at different grit effects in this preliminary bonding trial could also get me some surface roughness information at the same time.

_____

Observations

* The 1.5 pcf/15 psi XPS insulating foam clearly tears and crushes very easily. I can see how adding a wood veneer (Lavarat) or cork skin (melikefish) to the foam surface would minimize surface damage by dissipating/dispersing point impacts over a broader area.

* Notice the greater amount of foam on the (numbered) edge opposite the side used to peel up the glass patch. The peel edge was taped to avoid this effect. The opposing/numbered edge without tape -- with resin drip over the foam edge -- appeared to have much greater mechanical bonding/leverage (bottle-opener effect?).

* Uniformity -- while coarser grit appears to improve adhesion, it lacks uniform distribution over the entire surface. The deeper grit cuts pulled up the most foam. But the deeper cuts are random with gaps between them (areas of lower bonding?).

I believe perforation rollers could create more uniform mechanical bonding over the entire foam surface to be glassed.

I think I will look at the effects of perforation next. Sealed vs. unsealed? What final sanding grit before perforation? Too coarse, and the deep sanding grooves will likely impact the effects of perforation -- especially uniform distribution effects.

Adding perforation rollers for testing too has significantly increased the number of potential variable combinations**...**