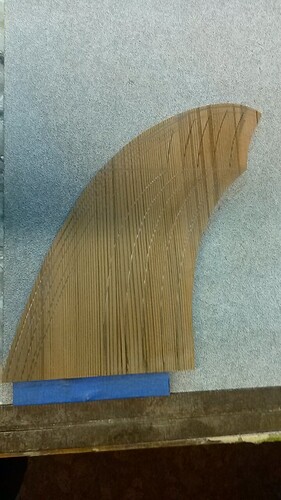

The wood is Western Red Cedar, some leftovers from my latest and final HWS build. Pretty soft and stable lightweight, and easy to work with, compared to harder woods

I used Gdaddy’s fin panel method for rail fins.

This fin panel I laid 3 layers of 24 oz woven roving atop heated waxed glass saturated with slow, but warmed epoxy, then weighted the warmed and presaturated cedar atop it. The roving does not go perfectly clear, not even close, I think it needs the styrenes in poly resin to do so as it seems there is a binder in it like fiberglass matt. Still amazingly stiff and strong and 3 layers is more simple than a dozen or more of anything thinner.

When foiled the woven roving forms a super strong and stiff core into the tab, and its own Halo. No additional halo required, but on previous fins when more halo was required I would lay roving along the edges prepped to receive them and then more cloth over it once sanded. Many stages. Too many.

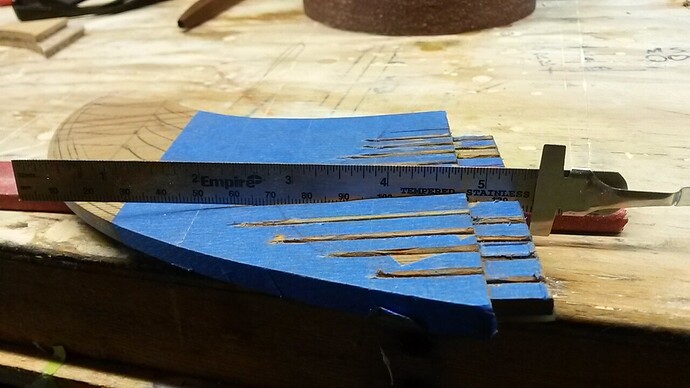

After foiling I ran it through the table saw to narrow the base a mm or 2 thinner than the receptacle, then rounded the thickest part of the foil over blending it into the tab, then laid several layers of 7.5 oz( I think 3 and one 3.7oz ) cloth atop, then a wood plank covered with plastic to press all the layers tight at the fin base then more roving to fill out the thickest part of the foil I rounded over pre-exterior glass. The base was still a bit too thin for probox, so I added more roving to make it thicker than the probox tab then ran it through the table saw to get a perfect thickness/friction fit of the fin tab with almost no additional sanding required.

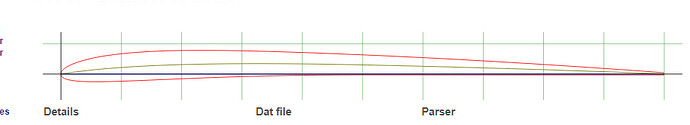

On my Many previous wood fins the thickness of the glass layers obscures the wood grain too much, so I try not to add too much glass and use the thicker core as the strength, but too little exterior glass on a previous fin allowed the wood to separate from core on impact with a douchebag’s rail. Too many layers of glass on the foiled side really stiffens the fin too much as well, and the flexless fins I have made lack spark. I like some tip flex to bend out of the way and impart less drag, but an highly skeptical of the claims that flex return/rebound rebound to add significant drive/projection. Perhaps a super lightweight board might feel more lively, but neither myself or my boards can be considered lightweight so rebound ‘twang’ seems more like a squishy delayed response under my feet

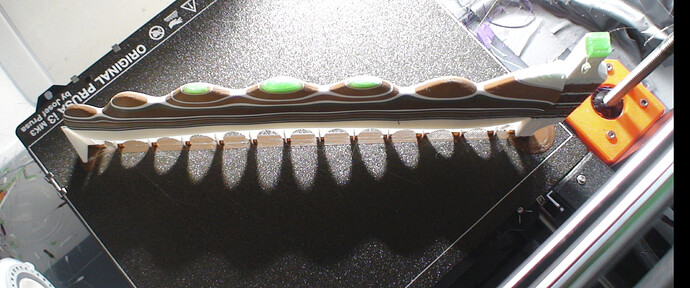

I moved the tabs forward on these fins to move the fin farther back in the board which made the sweetspot smaller and sweeter requiring more backfoot placement precision. While probox allows fins to move for or aft I built this one’s tab full length for no adjustment and less interference drag. These high aspect ratio fins with little to no rake need to be further back on the board. The previous model of this fin was even more upright and farther forward, but I broke one and lost one when some douchebag with a HPLB shoulder hopped me and I ran over his rail. These first sharky rail fins were enlightening though.

I am really appreciating the very low drag aspect of these rail fins, and they open up different parts of the wave face to extract speed from, especially with the 8 degree probox inserts. High up on the steep wave face and I’ve never felt such accelleration, most fins would stall at such an angle, and allow the tail to slide out but these grip and project almost unnaturally, and this might just be a novelty as it is a significantly different feel, which I enjoy, so far.

These twins are over 6 inches deep where regular twin fin offerings I researched seem to max out around 5.5, but I think there’s something to a deep narrow low drag tip in combo with high aspect that makes this unconventional outline work. These fins do not force one to draw out their turns like a heavily raked fin, in fact they do the opposite, unstable, little to no self centering, and can turn inside one’s expectations requiring a different interplay of rail and fin that takes some learning and of course is not applicable to each board and surfer’s style.

I’ve been playing with the center fin size to dial in the feel, basically taming the ability to overrotate, turn inside my desired line when pushed hard, but I basically need chest high or better conditions before I ride this board, so I don’t nearly ride it as much as I would like. The total fin surface area I am using with the center trailer fin, would seem like way too much fin, but it is not. Very Quick and lively with plenty of drive that make my regular conventional fins seem dull and listless in comparison.

I have enough fin panel left for 2 and perhaps 4 more fins, but, making fins as I do is so time consuming.

The little to no self centering of these rail fins and their general twitchy unstable but turbo nature seems to only be a detraction the first few waves when I have a longboard hangover going on. Once I dial in my back foot placement on pop up, and get some open face flow, I can’t find any aspect of their nature I’d want to change, but I’ve not had them out in juicy need to bleed speed types of waves, but imagine a bigger rakier center fin will add those attributes. My remaining fin panel is for rail fins though, not center fins. I’ve done the cedar sandwich of woven roving before, and will again though.

When I was using more traditionally shaped/sized rail fins and a smaller trailer on the same board, I was digging a high aspect ratio trailer more than any other center fin, but now am using a larger center fin that imparts some of that self centering stability lost with such high aspect ratio sharky like rail fins.

This board as a quad I have been unable to click with so far and stopped trying to, for now. The 2nd version of these sharky twins was way too upright with NO rake, too unstable as a thruster rail fin and I could overpower them, but might be well suited for a quad or perhaps 5 fin setup.

Variations of the regualr dolphin dorsal fin outline, especially as rail fins, is not doing it for me anymore, good thing I can make my own, and don’t care about the strange looks my fins receive by those who know exactly what a surfboard fin should look like, and can parrot futures or fcs marketing material verbatim.