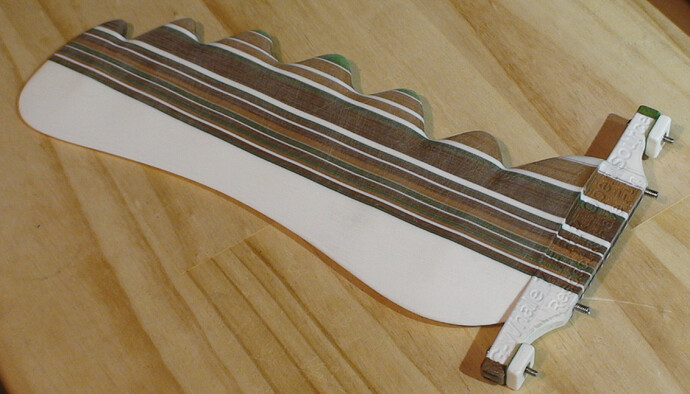

Really like the look of those thruster fins. .

The ‘quick and dirty’ part still baffles me, as I imagine the amount of effort required to get anything resembling that without a CNC.

Do you machine the tabs to the same thickness of fcs fins, or make them a friction fit inside the plugs @ ~ 0.5mm thicker?

The spitfire fins, I believe would need to be moved back on the board a good amount, since all accepted trailing edge shapers dots are considering the raked tips and the center of pressure is moved backwards on such a fin. Obviously this puts all the load on the rear tab and is a no go. I think that first tubercle can be extended a good 3/4 inches and the rest of the spitfire fin located back further to accomodate, but the rear tab is still going to take a majority of lateral loading.

The finbox location ideally would be moved to accomodate super high aspect ratio fins to spread the load more equally along the box/board, rather than adjusting the fin tab position.

With my limited experiments so far, the size and sweetness and position of the back foot sweet spot changes drastically with rail fin position with different fins or just using the ~1/2 inch that the probox can allow fins to move fore or aft… On my board, since I always have a tendency to initially put my back foot way forward in front of rail fins, I positioned fin boxes up the board further then lined up the wings with trailing edge. A rounded pintail throws a wrench into the equation too and I’ve been moving all my sharky fins back on the board, but still well forward of the usual 11 1/4". Before I began on my high aspect ratio fin kick I found I liked my backhand fin farther back and my toeside fin more in the middle to the probox range.

My newer sharkier rail fin templates have less base length than standard, are significantly deeper, and the trailing edge is about 1/4 inch behind the wing now buyt thats sure to wander with more waves ridden.

I’ve no idea what turbucles will do in regards to fore/aft rail fin positioning. Their ‘soft stall’ tendency is still too fresh and unexplored with regards to multifinned boards, and there is no base of experience to work from. I just think the best starting point regarding the higher aspect ratio, is the center of mass being the same as accepted positioning of regular raked dol fins.

With the higher angle of attack possible before stalling with tubercles. and that gradual progressive stall with a drag free feeling during the stall, is SO different, I can only guess what other ranges of cant/toe in, and foreaft positioning can become acceptable.

It strikes me that the turbucle fin in a stall is kind of like a ‘powerslide’ on a BMX bike, where the back wheel slides out but the wheel keeps spinning, compared to the person who locks up the back brake and slides sideways, and loses a majority of momentum by locking that rear brake.

I’d really like to see what a top 1%, rubber kneed surfer, could do with such fins. I imagine that one could ‘grind the coping’ for a lot longer, at higher speeds, and reenage the fins smoothly at will.

So many variables… not enough surf sessions