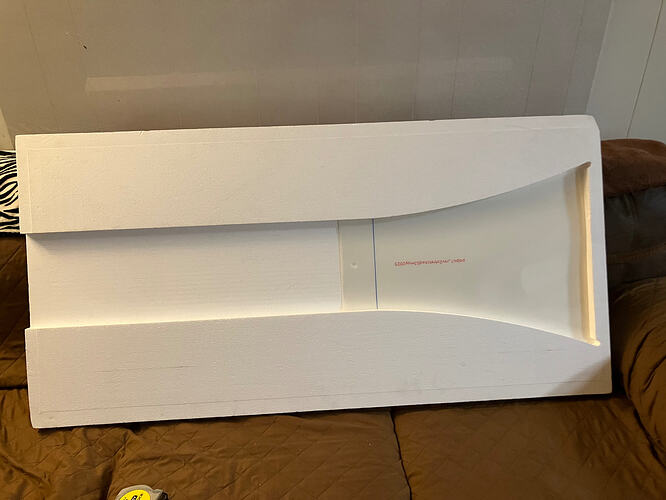

Got the 3-pcf EPS CNC test cut for potential basic-channel only blanks late this afternoon. Looks much better than Thomas’ pictures made it look. Beads are tight and pits are fairly small.

IMO this foam is usable for commercial blank production.

Christmas may have arrived early on Christmas Eve afternoon.

Stoneburner, where did you get the eps block? Looks great.

Chris

Got it from a company in Michigan.

It’s more of a sheet/slab than a block. Comes in different thicknesses from 1”-8” and 3 densities. But standard size is 24” X 48”. Apparently you can call for larger sizes — not sure if they ship for their larger dimensions.

Sent you a PM.

Jim,

Love the graphic art. Thanks! I’ve already posted it elsewhere (credited to you of course.)

Thomas ordered the 3” thickness but didn’t realize thickness tolerance is +/- 0.25”. This sheet/slab was 2.75” and not quite thick enough for the Paipo dimensions/shape in the CAD cutting file. So we turned it into a test slab to look at different cut methods.

But it is now 2.25” thick. Will have to knock thickness down to 2” to smooth out the deck side (bandsaw cut). The channel makes the center section only 1” thick. But I plan to hand shape the rails and play with some my experimental sealing and laminating methods anyway. Might even add a sheet of sandwiched cork to the deck.

Thomas and I still have to make three stages/levels of blank prototypes; rectangle with channel only, rectangle with channel and nose rocker only, and the fully shaped Paipo-HP — all from 4” thick 3-pcf EPS, usable for a final shaped thickness of 3”. All blanks will be stringerless.

I think some kink of build-up on the test blank would be interesting.

Sandwich cork + EVA foam for traction and padding. Sneak a 1/2” or 3/4” layer of EPS or XPS foam in under the cork if you need the volume.

IMO commercialization will most likely require re-evaluation of the foam supply chain.

An EVA deck pad is definitely part of the “tech sampler” build.

My potential business issue is that my CNC shaper is in ID. So anything not done via email has to be linear, e.g. purchase, shipping, shaping, shipping. The advantage of the current foam supplier is 3-pcf foam and free shipping over a threshold $ purchase amount. Paying for shipping twice is a cost-of-production killer.

That is, foam supplier to Thomas (free) then shaped blank shipped directly to customer (shaper/glasser). Complete shaping of “my design” is an option. However, with a channel only blank, the customer can do their own final shape. Both options require glassing on the customer end.

Current issue for a complete shape is the cost of Thomas’ CNC cutting time. However, with a basic-channel only or channel&rocker only blank, price may be acceptable because of the difficulty shaping an accurate, precise channel (especially by hand). Flat/no tail rocker, specific channel curves, perpendicular channel walls and hard, channel wall edges/angles are critical for correct channel function.

And these are just a few of the “basic/primary” considerations, assuming we can work out shaping issues with prototypes. At this point, Paipo/BB size has to be no more than 48” long and no more 24” wide.

To quote Sam Elliott in the last episode of Landman (S2E6);

“Trust me. Living off of memories ain’t no living at all. You got to make them while you can.”

Very cool! Clean cut. I like what I can see of the rails as well.

I’ll post more photos when I get it. We’re not going to ship until he completes another to go with it.

Recently cut 3-pcf EPS Channel Blanks have arrived.

One fully shaped the other a basic slab with channel and nosrocker.

One more modification and these should be ready for the public.