Seeing that Australia Post envelope in the mail box, reminds me of being a stoked frothing kid on Christmas morning, but the true joy begins when paddling into a wave with one of these fins installed.

The latest edge protectors with extra screws and break away screw plates are indeed an impressive design.

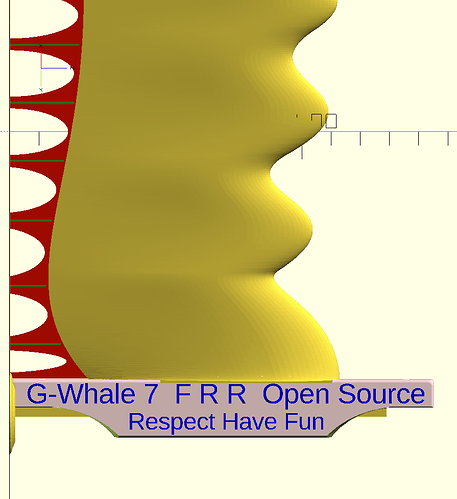

I have an exact version of the fin on its way to Hans, regarding thickness and flex, filament and color, but i have wetsanded mine smooth to 400 grit. It has a brighter spark than the others. On some waves, when grabbing the rail and torquing/leveraging both fin and rail to get going quickly on a stretched out wall, they combine to make it feel like one just stepped onto one of those moving sidewalks at the airport. If this happens when not grabbing rail I get stuck on just my back foot or fall off the tail. This partiular fin is very lively and predictable and confidence inspiring, a slight degree more so than the other G-whale fins.

Also on the last wave in, proned out in the white water, and angling as hard as possible up or down the beach, no fin ever, has allowed the steep angles parallelish to shore that I am achieving, nor the speeds I can achieve with this Gwhale fin. More than once I found myself back on open face, never having expected to catch back up with it.

All the fin base strength issues, seem to have been sorted out. I’ve been instructed to try and break them surfing, turning as hard as I can. Kicking the board out backside up and over, has been the fin breaker in the past, and the new base designs are not breaking when doing this. Even some more recent version which are not as strong as the latest have not broken.

I’ve not really driven them into sand very hard as I can’t intentionally destroy anything that is so joyful, and I do fear wrecking my finbox, but my 25LB leashless board has hit sand and cobbles on the beach loading the fin fore, aft, and laterally and rotationally without issue so far.

Getting the fin base tabs, both leading and trailing edges, to sit flush with the hull and also resting on the base of the box, is now easy to accomplish on any board, Something which cannot be said for the single tab on fins with roll pins as each board is slightly different when finbox is sanded to the level of the hull. One could also slightly alter the aspect ratio a degree or 3, if they wanted to, and were not much concerned whether the tabs are flush with the hull.

Fins with thick flanged bases, the flanges can now reside directly on the hull adding lateral strength to the fin base, and also add resistance to lateral flex at the base which I feel is great for quick responsiveness to input. The thicker fins feel more solid during hard turns, but are noticeably slower on open face in trim, but still way faster than my regular Dol-fin. I’ve only one session on the latest fin sent that has a flanged base and tapers to the same thickness at the tip, in weak small conditions, and it did turn quite well, but no opportunities to compare that trim speed to fins without flanged bases.

My 16 year old longboard’s fin box is so worn and stretched out from fitting fins previous to the latest dual tab versions, that dang roll pin requiring sliding, that I have to thicken the base of all fins I use in this board, with epoxy, so they do not wobble obscenely in the box. My finbox is heavily reinforced, and capped, so I’d rather not have to route it out to install new, but I do spend a lot of effort thickening each fin sent, and then sanding them to fit tightly.

This means that fins I have tested, are too thick to insert into almost any other fin box without sanding the sides back thinner, and it is amazingly difficult to sand fin bases evenly thinner without tapering them, which induces base wobble and lack of instant response to input.

So I have only gotten one G-whale fin into another’s hand at this point, and pretty much want to fit the fins to others boards myself, rather than allowing others to do the base thinning fine tuning.

This G-whale fin now in the hands of another, is one which was too flexible for me, which I suspected before riding it, and whose unmodified base I shimmed with construction paper and wetsand paper, instead of thickening it with epoxy, which is superior but much more labor intensive, in terms of efficacy in reducing base wobble. This person had been handed the tri color Harftub 9.5 shown in the first pic on page one in this thread some 7 months earlier. I heard through the grapevine he was raving about its speed and control on a HPLB with side bites, but apparently it broke and he was trying to fix it as he liked it so much when I saw him again, and handed him a 7 7/8" deep version of the ~9 5/8" deep fin he broke, and the super flexy Gwhale with the new screw plates, metric screws and allen key to drive them.

Performance wise, If the Harftub 9.5 earned a 6 out of 10 in my longboard, then the Harftub 7s was closer to a 7 / 7.5, and all the stiffer G-Whale versions are a 9.0+, and my regular raked fin is a 4.5, in my opinion.

The lower aspect ratio deaweeder fin earns a solid 5.5 to 6.5, and feels much more like a regular dol-fin in a straight line and through turns, but is nowhere near as quick and responsive as the Higher aspect Harftub and Gwhale fins, but is noticeably faster and looser than my traditional Dolfin.

Trying these lower aspect ratio fins in this board after riding so much High aspect ratio fins, made it obvious the self centering, added stablilty, and added drag of lower aspect ratio, and rarely did I find any of those attributes desirable in this board. I was being caught behind on waves I expected to be able to stay on open face, feeling the extra drag, and pushing hard during turns, the board was not coming back around under me as I was used to. I was having to alter my line and not push nearly as hard to keep the fin from stalling and falling in turns, and I much prefer to push hard.

The Gwhale fins whose bases I broke, have been cut down to shortboard multi-fin size, and works amazingly well as a center fin in my shortboard. They need to be 3/16" or more further back than the trailing edge of regular thruster fins and in that position are very drivey and still loose and quick, but can catch the leash going from sitting to paddling, and not let go, so one has to take more care with the leash over the shoulder when sitting and prevent it from wrapping around a turbucle.

I am going to borrow a board with Futures fins and modify another GW fin to tightly fit that system’s center box, and perhaps FCS2 at a later date as I want a dedicated HPSB rider to try one. I use Probox myself.