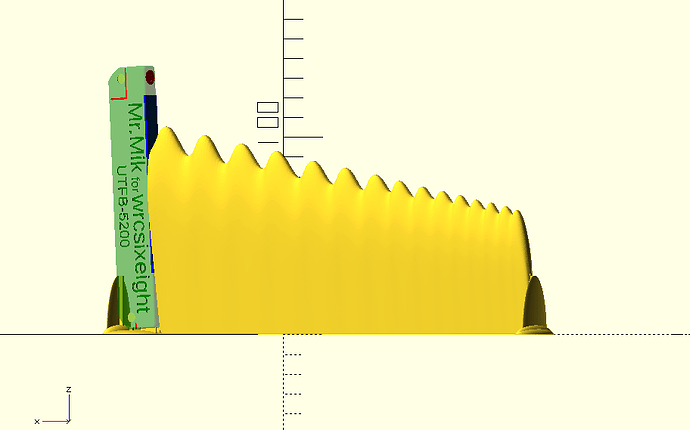

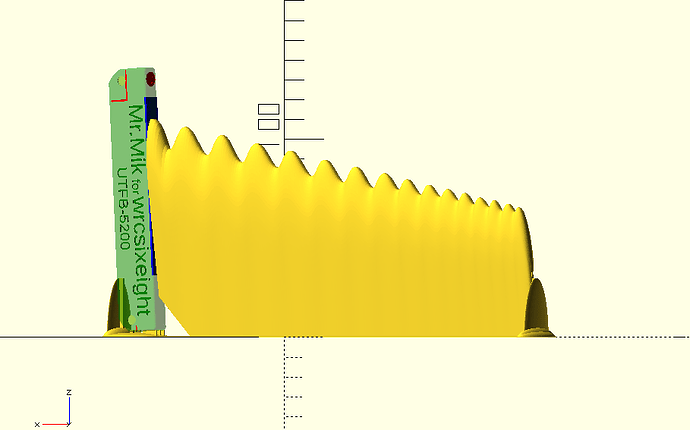

I want to know if a ‘Forwardly displaced fin root section’ is making a real difference when using a tubercled leading edge on a fin.

And I have the same question regarding a ‘trailing edge cutaway’.

.

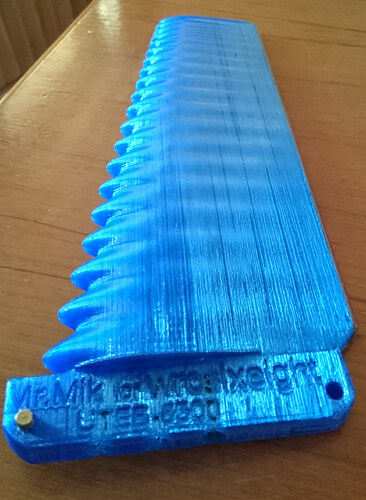

With a couple of hours worth of tweaking the OpenScad code, I was able to change the HARF-9.5-TUB into a HARF-9.0-TUB, and the HARF-15.5-TUB into a HARF-15.0-TUB.

.

The HARF-9.0-TUB has already been printed and the HARF-15.0-TUB comes next.

Love it.

I’ve saved a backup copy of this page at archive.org

All 5 3d printers at my local makerspace are broken so I’m going to have to lasercut and hand foil. Ordering the fin online out of nylon is $50.

All the print beds here are too small for the fins anyway… I wonder what you’re using to print them and how.

How does the archive.org work?

I’m still adding to the post that is intended to be found by patent searches, I might have to put it into archive.org again later.

Follow the links in the long post on the previous page, all the info is there.

I use PLA.

Printing from Nylon would be too flexible, I think. Been there, done that.

Polycarbonate would be the way to go if you use a professional printing service.

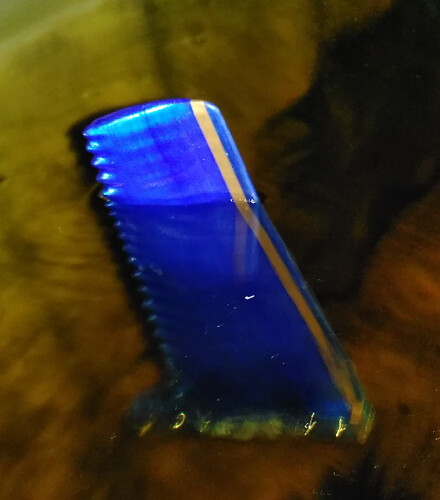

Here are some pictures to show how the adjustable surfboard fin safety release system works.

The parts shown are V600 and do not include the catch-rope option.

The blue and the red V600 retainers have the same shape. They can be used either with the ball spring plunger, or with the printed nipple engaging into the locator-nut on each end of the fin tab (UTFB5300).

Haven’t read your threads word-for-word and I’m not even sure I have posted this on your threads before…but here is a great option.

I have been using the Kumano System for years with great success. They are the ball system that was in your old McCoy fin. Anyways, you can still buy them and the company is excellent to work with.

Using the Kumano system has fixed many issues I once had with making fins that have a long base fit into the standard 10" box. Place the pin in front…bearings in back and good to go.

Dave

Thanks Dave, I think you pointed this out before. Looks like a good system, but the ball spring plungers cost 4 x more than the ones I use.

I want the fins to come out when an impact occurs from fore or aft. That makes it much safer.

My safety fin release system is also adjustable, or at least has variable ‘settings’, whereas the Kumano system does not. The roll pin needs to break before the fin comes out. Then you loose the fin, and maybe the board and/or the box has been damaged.

Other advantages include that the empty space in the box gets closed (later version, not shown yet), and that the fin position is determined by the retainer positions.

An Allen key is only required if you want to change the fin position.

Eventually a catch-string will be included to keep the fin with the board if it gets knocked out of the box.

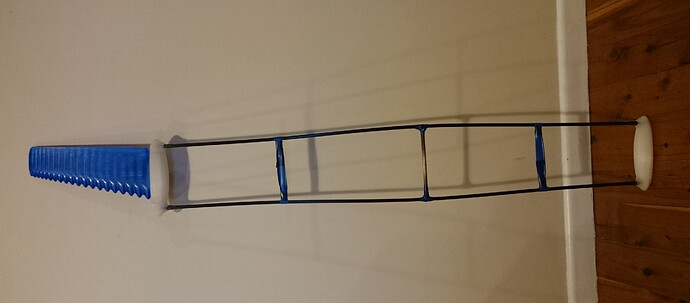

A heap of fins to be tested.

.

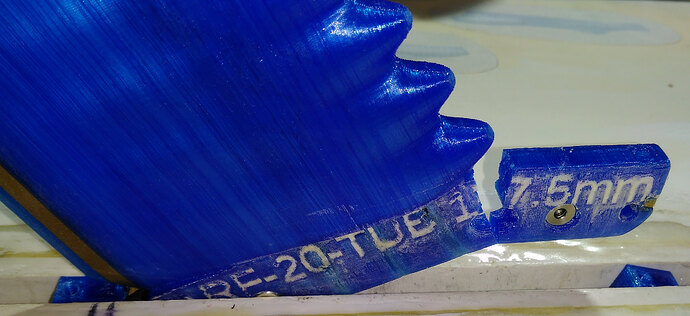

I put together a package of fins for wrcsixeight to try out how they go in the surf.

.

1998g packaged up, 8 fins, 3 sets of safety release retainers, and a few ball spring plungers.

.

HARF9TUB-83% is a shrunk down version of HARF9TUB. The fin without UTFB is 200mm high instead of 239mm. Unfortunately I split the layers between the main purple and the white line in the aft tip area, when I carelessly used a rasp to remove the support system remnants. I glue it back together with Tarzans Grip Mega Bond.

.

HARF25TUB 100% really has 26.0 tubercles in an almost straight line along the leading edge. It should answer the question if very many, and very small, tubercles are better. Some of the research papers on tubercles seem to suggest that.

.

HARF-26-F-TUB 100% is my attempt to create a fractally tubercled fin. Maybe combining 26 small tubercles into clusters of several larger tubercles combines the best of both worlds. In order to make the grooves on the foiled surfaces deeper, I had to make the fore tubercles quite sharp and pointy. I think it might be just as effective after sanding back the fore points, but I think it’s a good idea to surf it before blunting the points just to see what it is like. Needless to say, this fin should only be mounted in the fin box with the safety fin release system set to easy release, in case of a collision with another surfer. Probably also a good idea to only surf it at select times and at locations with few other people in the water.

.

HARF-15.5-TUB is the green-white-blue one.

.

HARF-20.0-TUB (white with red trailing edge) has been re-arranged so that the proximal tubercle starts with the trough emanating from the base, rather than the peak. This fin is my personal (so far only theoretical) favourite. It’s just ‘intuition’ at this stage, but I think it will likely be close to the sweet spot of reduced drag (close to Wavegrinder2 drag levels) while retaining the increased lift, predictable behaviour and forgiving stall of the HARF9.5TUB. Big call, I may be completely wrong about this.

.

The two Wanderfalke E168 fins should help to determine if the bumps make much difference, and if the exaggerated concave foil on the first Wanderfalke fin I sent earlier is much different from the Eppler 168 foil.

.

The eighth fin is a ‘remix’ of the HARF9.5TUB that wrcsixeight has been surfing a few times. It is HARF-9.0-TUB and has the first tubercle starting with the trough emanating from the base, instead of having another 1/2 tubercle starting at the peak. It would be most interesting to know if the disappearance of the proximal 1/2 tubercle makes a difference one way or another.

Wow, 8 more fins to test!

A few of my friends believe me about the harftub9.5 and want to try it, many think I have finally lost my mind and skoff at my claims, much as I suspect most readers here do. I don’t blame them in the slightest. I would be right there and was, before actually trying them.

I was starting to doubt my own sanity until I used my regular raked fin in my 9’7" again and was simply disappointed. The raked traditional fin felt slow, it was coming unstuck when i was in 2/3 trim grabbing a rail trying to power around a section, and it required much more effort to turn sharply, well as sharp as a ~25LB old school 9’7" longboard can turn anyway. Sinking the tail to spin around late for a one or two paddle takeoff, well the extra resistance of the raked fin of much more surface area, caused me to be too late, and completely screw up more than one wave, and a relearning of the slower response time was required, and not stoke inspiring.

I am most eager to try out the 83% fin.

While none of the ~9.5 inch deep fins feel too big, they are very very far away from feeling too small and I want to reduce their depth until they approach this.

My judgement of this fin size/depth is when behind a section but at speed, grabbing a rail on my backhand, and angling as hard as possible in the quest to return to open face ASAP, and ‘make’ the wave. The turbucle fin never busts loose when doing this. I of course did not always make it back to open face, but when I tried this same technique with my regular fin back in the board, the fin broke loose and all hope was then lost, but the regular raked fin is also slower which reduced the likelyhood of getting back to the open face even further, and the difference between the two fins in this situation was unmistakably profound.

It really feels like the turbucle fin, and WG2, has half the drag and nearly twice the holding power with the WG2 having a clear edge on speed over the turbucle fin.

The WG2 fin can however do some weird things during the second half of harder turns, Sometimes interestingly novel, like the feeling of a downturn back into the pocket and accellerting like the nitrous injectors are stuck open, other times the weirdness causes a fail and a fall , but this ‘weirdness’ is completely absent on the turbucle fin, but the turbucle fin does not have the same blistering speed of the WG2, but is still way faster than my traditional raked fin.

The only detraction I can find is it is a kelp and sea grass catcher. When it catches a 3 foot long piece of kelp, with 6 inches on one end and 30 inches on the other side of the fin, near the tip of the fin, the board then feels pretty much exactly like my regular raked fin, but perhaps just a little slower. If it catches closer to the base of the fin then it feels draggy, but not the same way as my regular fin does in comparison.

Hard to describe, but when dragging kelp anywhere on the fin from base to tip, it is quite obvious, but the kelp has to be pretty large before it feels as draggy as my regular fin does, and this, I know, is hard to believe and your doubt at this statement is completely understood.

It is Just surprising that if Kelp does catch near the tip of the fin, how incredibly similar the feel is to my regular raked fin.

Now some might say my regular raked fin is foiled badly or has a bad outline and this is the reason for the easily apparent superiority of these high aspect and turbucled fins. It has no flat spots, and is slightly more flexible than the Fins Unlimited all fiberglass version that I took the template from back in 2003. I have actually used that all fiberglass fin in this same board and felt my wood fin was superior. It is perfect? obviously not but it is not such a bad fin one can attribute the superiority of Mr miks fins simply to the fact that my regular fin was badly made or foiled according to conventional fin designs.

When I know I have caught some kelp and am ending the ride, I initially had been trying to keep some forward speed to retain the kelp on the fin to see the size of the kelp and where on the fin it has been dragging from, but I later found the kelp is pretty well attached to the leading edge of the fin without the extra effort of trying to keep forward momentum to retain it in place.

The base to tip 3D printing striations are fairly pronounced. I have wetsanded them and recently applied an Epoxy gloss over them. I hope this will help the kelp/ grass slide off easier as the striations/ ridges seemed to impale the Kelp or grass and then it would stick to the fin. With the sea grass it would break, rather than slide off the turbucle. The WG2 fin and the Mr Miks skightly different foiled WG2 clone, the grass/ kelp was always at the tip of the fin on the winglets. with the turbucle fin it could be caught anywhere on any turbucle.

The Kelp catching proclivities are a fairly big detraction though. Almost every time I paddle back outside I can find at least some grass on the fin when i jump off and lift the tail, and some other times i do not see the obstacle, yet still feel something catch and start dragging just when paddling. When positioning for a wave to get as deep as possible, and if there is kelp in the way, well going around it adds a new element rather than simply going over it knowing it would eventually slough of a regular raked fin. I have jumped off the board a few times to clear the fin, and also am now paddling backwards after triangulating my position to clear the fin before sitting on the board.

There are not huge amounts of kelp and sea grass in the line up most of the time here, but the turbucles are acting like a rake, and ‘clearing’ the fin adds a new element to riding waves. Well worth it though. I love how the fin feels underfoot, until there is a large piece of kelp being dragged. Small pieces of kelp or sea grass and it is still better than my traditional shaped fin.

I can say with confidence, that in my singlefin traditional style longboards, that these fins are not just novelties with a different feel, but a significant improvement in trim speed, and maneuverability and confidence, and are giving me more stoke to surf more often and my mind is a bit blown that the ‘conventional’ and widely accepted longboard fins are seemingly little better than a piece of plywood hammered into a finbox.

The other day while having the harftub9.5 in drydock for reinforcement of fin tab for screwplate, there were waves to ride, and the session the day before with my regular fin back in place, while I still had a lot of fun and good rides, was such a disappointment in comparison, that I decided to instead work on getting the harftub fin operational again rather than go surf my regular fin again.

I do have some reluctance to even surf anything but the original blue turbucle fin MrMik sent. I would glass this fin into my board with little consternation.

I will try them all. If the WG2’s ‘drag free’ speedy nature can be combined with the turbucle fin’s responsiveness crispness and forgiving nature it is a true game changer. How any of this applies to multifin applications and that much different style of surfing is unknown to me. I have some of the stiffer Quad wavegrinder winglet fins to try, but I need chest high or bigger surf before I will bust out my 6’8" thruster, and give those a feel.

But, I’ll be surprised if in 5 years HPSB fin templates will appear as they do now.

" But, I’ll be surprised if in 5 years HPSB fin templates will appear as they do now."

That’s the beauty of original thought, MrMiks done things that a hundred fin companies coulda, woulda, shooda done, but didn’t. While all the other companies are touting the benefit of millimetre variations MrMiks making quantum leaps. Amazing work.

just copy and paste the page you want to backup into the save link box on the right at https://archive.org/web/

Thanks for all the praise, surffoils and wrcsixeight, much appreciated.

.

wrcsixeight wrote" The only detraction I can find is it is a kelp and sea grass catcher. When it catches a 3 foot long piece of kelp, with 6 inches on one end and 30 inches on the other side of the fin, near the tip of the fin, the board then feels pretty much exactly like my regular raked fin, but perhaps just a little slower."

I think the drag caused by sea grass at the tip may be very similar to the drag from the tip vortex of a conventional fin without winglets or tubercles.

And I wonder what they do to get rid of sea grass (and plastic bags, fishing line and the general debris of ‘civilisation’ floating around the oceans) on high aspect ratio keels and rudders, particularly with tubercles. Without intermittent stopping (between waves on a surfboard), the boats would accumulate much more debris than a surf board fin will.

.

If you want to trim a few fins by removing a tubercle at the time from the tip, then consider using a saw and keep the plastic. It can be heated with a hot air gun and used to make repairs to the fins.

.

The thickness of the print layers can be changed, it may be worth doubling the print time once we know which shape works best. These fins were printed with 0.3mm layer height.

.

Using the printing techniques I developed and then paying a professional 3D printer to make polycarbonate fins will possibly be an option once prototyping is finished.

Now the fins float again.

I printed a thicker version of the HARFTUB-20 with combined solid base, partial fill in the tip, and carbon tube inserts.

It floats in fresh water.

.

Fortunately I decided to destructively test the effectiveness of the safety release mechanism. I found out that the fin tab snapped off before the fore retainer would release the fin tab from the box. A very firm whack with open hand from fore was required.

.

This ‘bad’ result led to a day of redesigning the UTFB for HARFTUB fins, resulting in a much more elegant solution.

.

I shortened the fin base and removed all ball spring plungers when I realised that ‘old thinking’ was stopping me from using the ‘weakness’ of the PLA to my advantage.

.

The fins can simply be secured in the box with a fore roll pin. The roll pin will break out in a severe impact scenario from fore and release the fin to float. The aft part of the tab gets pushed into the fin box and is held in by it’s soft flexible properties and a little bit of warping. If the fit is not good enough, then dip the base in hot water (a bit too hot to stick your hand in) and then bend the fin base a little bit and let it cool. That also allows to ‘set’ the fin angle perfectly if you insert the hot base into the board and then adjust the fin while it cools.

.

This new version is the UTFB-6500 and it uses minimum cost and material, but allows tool-less adjustment of the fin position in the box, and gets around the notorious problems of poor fitting in various fin boxes. On size fits all!

.

Only problem of not using the ball spring plungers is that the fin floats too much. It ends up lying flat on the waters surface and is then a lot harder to find. I might have to add some weight. Maybe a piece of lead in the rear roll pin hole will do it.

.

The UTFB-6500 is also allowing to use the fin as standard screw in with a roll-pin aft. Markers are 3D-printed into the fin to show where to cut and drill if this is desired.

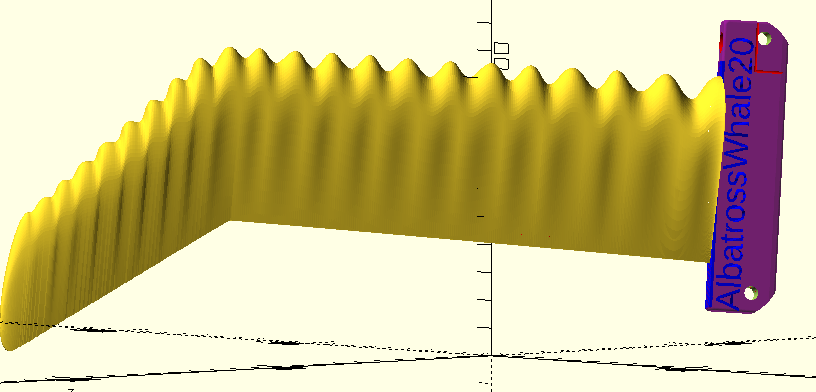

Now I’m getting closer to what I had in mind from early on in my fin making efforts: The Albatross-Whale-Fin.

.

Just a ‘tiny’ overhang to be dealt with before 3D printing it…

The first successful print of the Albatross-Whale fin.

.

It may be a complete dog of a fin, entirely untested so far.

.

Around 35mm thick at the base, about 17.5mm thick for most of the middle part.

The reason why I’m not too confident about the Albatross-Whale fin is some recent unexpectedly poor performance of the HARFTUB20.0 fin.

I have not surfed it myself yet, and the spring conditions don’t look like it’s going to happen soon, either.

But, wrcsixeight had 2 sessions on it and is apparently worse than a ‘traditional’ raked fin. No redeeming features, just basically a wasted surf session. Now I’m trying to figure out why that is so.

.

It could be that the first tubercle close to the tab must be a 1/2 tubercle, or somehow a lot of additional drag is created where fin and board bottom interact. Or, too many small tubercles make things worse rather than better.

.

A few tests with other fins may eventually answer the question ‘why’. But, I cannot expect people to waste surf sessions with poorly performing fins. I need to surf more myself and I need to have a testing method that ‘might’ weed out the very bad fins without wasting a good surf session.

.

Once the waves improve (it can only be a matter of months), I need to somehow take an extra fin into the lineup and then swap fins to compare them in similar conditions. I’ve been barking up the wrong tree trying to switch fins with other surfers, it’s just too hard to organise. So I’ll switch fins with myself. Maybe a couple of camera mounts can be re-applied for good purposes, to strap a fin securely to the deck of my board. On an 8’0’’ Nugget there is plenty of space …

.

Meanwhile, I’ll have another go at testing fins by hand, in the pool. Previously, I tried moving the fins under water while holding them by the fin tab, but it’s hard to get a clear impression of differences between fins, presumably in part due to the large interference from hand and arm dragging through the water.

.

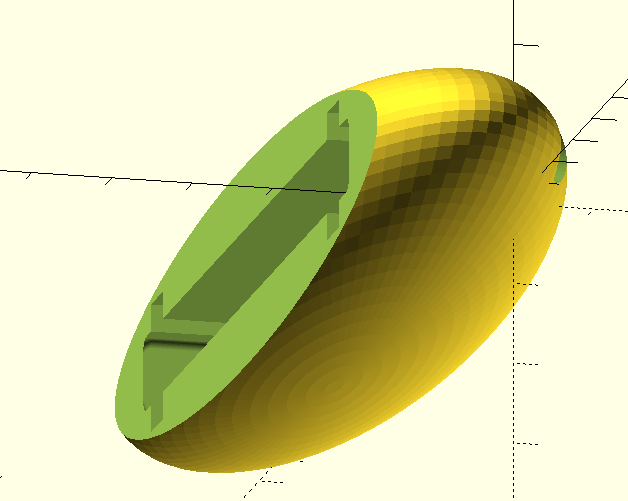

So I designed a fin testing rig, which is also still untested, and prepared a few fins that all fit neatly into the streamlined ‘torpedo-fin-box’.

The handle at the other end of the reused carbon arrow tubes is an earlier print of the torpedo-fin-box. It will be replaced by a larger torpedo-fin box for use with the longer UTFBs for the GullWhale fins.

.

New carbon tubes should arrive tomorrow, with 1m lengths I might be able to walk along the edge of a swimming pool with a fin just submerged in the water, with out hurting my back. Time will tell…

.

I prepared six fins so far which all fit nicely into the ‘torpedo-fin-box-test-rig’.

From left to right they are:

- Albatross-Whale fin; very thick, 21.5 TUBs

- HARFTUB20.0 x 17.5mm thick

- HARFTUB20.0 x 12.5mm thick (exactly shaped like the one which ruined wrcsixeight’s session)

- HARFTUB20.5 x 12.5mm

- HARFTUB9.0 x 12.5mm (has 1/2 bump less than the ‘magic’ one)

- HARFTUB9.5 x 12.5mm (the ‘magic’ one)

I think the ‘torpedo-fin-box’ may have a severe shortcoming regarding detection of drag caused at the interface between fin and board.

Because there is no board, the effect of the 1/2 tubercle (or a cutaway at the trailing edge) may not make much difference with this rig, when they might make a lot of difference on a surfboard.

.

Ah, well, it will be fun making a fool of myself at the pool…

My surf session was not wasted, it was helpful in determining that either more turbucles are not advantageous, or perhaps the lack of a half turbucle at the base of the fin is causing some ridiculous amount of interference drag, or some combination of both. The other fins you sent should give some more basis for comparison, but my friends who are wanting me to send them a harftub9.5 will have to wait, as so far, these two are my favorite longboard fins ever, by far, in either longboard.

The harftub 9.5 is so incredibly forgiving and good natured it is hard to believe that further refinement was not called for, but the harftub 20 was a dog that felt like i was dragging a sea anchor or a giant wad of kelp 95% of the time.

These fins look small in the boards, and when pushing the tail around when wading out in waist deep water, there is very little resistance to pushing the whole tail sideways, but when up and riding they have an incredible amount of hold and grip and just go where you point them without any protest. The Harftub9.5 does not feel draggy, the harftub20 was horrendously draggy. The wingleted turbucleless WG2 clone is the speed demon that is sometimes reluctant to respond to inputs in certain parts of certain waves, but it will, from here on out, always my first choice when there is a lack of grunt to the swell.

So far the harftub 9.5 is really my favorite fin I’ve ever used in a longboard, even though it is not as speedy as the wingletted WG2 clone.

I’ll definitely try every other fin you have sent, startng with harftub9.0, but I will consider bringing the harftub9.5 with me to the beach as well just incase they act like the hartub20 which I wanted out after the second wave, but struggled through 25 more.

The swell is currently so lacking with no real hope for some more juice in the immediate future, that my bigger longboard and the WG2 clone will likely be the goto fun inducing combo. Where conservation of momentum is more desirable than harder turning or pocket stalling, which the harftub9.5 seems overjoyed to participate in. I don’t really want to test the turbucle fins in extremely weak conditions as they seem happier when there is more juice/size. The WG2 winglet fin is just so speedy when paddling, paddling for waves, and riding the waves it is a bit hard to give that up when there is a lack of grunt.

I kept thinking during the session that the harftub20 perhaps felt so draggy in my smaller LB as I had been riding the WG2 fin a bunch in my bigger LB, which is also faster, but it became increasingly obvious with each juicy section I did get to, that there was something funky happening below. I’d kick out and flip the board over expecting to see a giant piece of kelp stuck to the fin or nearby, but nothing. When I was expecting some squirt nd projection I was finding myself off balance on my front foot as the squirt did not occur.

The 83% harftub9.5 looks way too small in my smaller LB. It did not feel too small, not even close, but at 7 7/8" deep, did not really feel much different than the 100% 9.3/8 inch deep harftub9.5 which I found very surprising. But I only had the one session on it, and I began that session with a wavegrinder trailer quad fin in my FCS plugs behind FU/bahne box. That smaller quad wavegrinder fin broke off when I was kicking out of a wave, and I will not be trying wavegrinder shortboard fins I was sent, in my shortboard as they are not mine and I do not wish to replace them all or have them break off underfoot on a hard bottom turn and ruin my session. That was an issue for me with FCS fins when they first came out. The Tabs were always breaking off, it was just a matter of time.

I did not like the feel of the 83% harftub with the wavegrinder trailer fin and enjoyed the session much more after the wavegrinder fin broke off. With the trailer it felt stiff and reluctant top respond to input the faster I got going. With my normal raked fins on this board on which i used a trailer, this was not an issue, but the Wavegrinder smaller quad fin behind the 83% harftub9.5 was not an enjoyable combo. To be fair my usual raked trailer is about 3.5 inches deep and the smaller wavegrinder quad is 4.81 inches deep.

The ‘Fin-tester’ was most enlightening. It still needs refinements, like adding grub screws to secure the fins better, and an overall better build quality, stiffening, etc, but it works well at the poolside.

.

Timing it right for when all the kids have to go and eat dinner is important…so the pool is deserted.

.

Lessons learned:

-

It’s unbelievable how much drag a pair of in-line 7mm diameter carbon tubes will cause when dragged through water.

There is a reason for using foils, and it becomes very obvious when this tester is lowered just a little deeper than necessary. The stiffening planned for the whole contraption will involve foiled 3D printed covers for the carbon tubes, to make the whole thing more forgiving regarding exact depth of insertion into the water. -

I think I can feel a difference in drag between thinner and thicker fins when just going straight, but maybe not really at speeds that can be attained by paddling alone. Needs more testing…

-

I don’t think lack of 1/2 tubercle at the base is behind the ‘dragginess’ of the HARFTUB20. Instead, it is humming! Both the HARFTUB 20.5 x 12.5mm and the HARFTUB20.0 x 12.5mm produce a vibration that I can hear and also feel through the hand holding the fin-tester. I guesstimate it’s between 400Hz and 800Hz, not sure how to determine that more accurately and/or if it matters.

What matters though is that the HARFTUB20.0 x 17.5mm (with carbon tubes, hollow print, it floats) does NOT produce a hum at speeds I can achieve with the dodgy fin-tester. Once I have the fins securely attached in the tester, I can be more adventurous without risking that the fin goes flying off. That might show that the HARFTUB20.0 x 17.5mm also hums eventually, but I doubt it. The carbon-tube version is so much stiffer than the solidly printed version, it’s resonance frequency must be much higher. -

The Albatross-Whale fin certainly has the tightest turning radius of the six fins tested so far. I think it produces less lift than the others, but it shows none of the draggy characteristics of the 7mm diameter carbon tubes, and no detectable hum at the speeds that I can currently test. I’ll take it for a surf when the conditions are right. If it needs to have a bit more cord length, no problem. There is more than enough space left in the ‘printable volume’ of my printer.

-

I still think the HARFTUB20.x is the best fin in the series. It’s consistently draggy performance (in the solid-PLA-print-version) actually proves the point.

.

I think it whistles a tune rather than create lift.

.

The reducing amplitude and increasing frequency of the tubercles cause counter-rotating vortices between pairs of tubercles (as always), but in this case the vortices have multiple (different) frequencies.

Therefore a fin like this will likely encounter several different resonance frequencies as the speed of the surfboard increases, causing variable but almost always present drag. And the better the tubercles are arranged for gradually changing frequency and amplitude, the more consistent the drag from induced vibration will be across a range of speeds.

And the more varied will be the tune that it whistles.

.

If the fin is consistently draggy across a range of speeds, then it’s well tuned, but just too floppy.

.

Stiffening (carbon tubes) and dampening (partial infill areas that bend but don’t ‘swing’) might well fix this issue.

This newly printed ‘Tanker’ tester holds both UTFB6520 and UTFB 4203 fins.

.

It is designed to detect extra drag caused at the fin / board interface, To test half-tubercles fore and cutaway aft, and such stuff.

.

I started the print before finding out about the massive drag from the carbon tubes, so the next iteration will have foiled towers like a submarine to cover the tubes. I might also include a handle for hand-holding under water, without carbon tube extension.

Hopefully I can integrate it all into one design.