That shape looks fun. Hope you have enough foam to make it without having to add any.

gavz ,

this is only me ....

BUT !!!

...... I would leave it the size , and shape, that it already is !!

and thin it down to 3 and a bit inches

WHY ?

By the looks , what you have there is / looks like a really fun gun shape , in good nick !! Lucky you ...SCORED , mate ...25 bucks ??? wooweee !!

A GREAT board to use as an alternative small wave mal in summer , 'if' it won't get used in any large stuff , perhaps ?

the very most I would take off would be to get it down to 9' , possibly

q:

What are the nose and the tail rocker measurements for it , as is , please ?

Me , I have always regretted having boards that were too flat because I cut them down too much when , if I had stuck to the original boards rocker , I would have had a MUCH better surfing board , for a wider variety of conditions .

......here's a true life story , as an example for you and others to consider ?

I once reshaped a perfectly good [if old! ] 9' longboard blank , into a 5'5 x 19 1/4" flat-as-an- ironing-board "fish" , which didn't work at ALL !

How I wish I had that 9' blank NOW ...the shortest I would go would be 8'6 , if I had it now [as I already have a 9'4 , which , apart from TINY days , I find waaay too long , really .]

so...

WHY did i shorten that blank so MUCH ?!

That is a very good question , really [that I probably needed to ask myself , BEFORE putting saw to foam !]

the only things i could think of , now , are

because ...

1. i was much younger , naive / narrow-minded , and thought at the time "you will NEVER catch me riding a mal !" [?!] ["never say never ", is the lesson to learn there , i think ?!]

2. a mate gave me the blank [free ]

3. i wasn't thinking

4. 'Swaylock's , computers , and the 'JC shaping and glassing' videos were not yet available , then

5. i had no clue ! / was stoopid !

.... [hopefully , I ] live[d] and LEARN[T] , eh ?!

cheers mate !

ben

Haha shit… I already committed the offense and cut down the blank last night. I see what you’re saying, though. Next time I stumble upon a big blank I’ll fit something more size appropriate into it. The original sailboard had a crazy amount of rocker in the nose, probably something like 6 inches. Zero in the tail. The board im shaping is 4" nose and 2" tail. Before I cut down the blank, I moved the template around a bunch to try and find the spot that best accomodates the rocker and the width of the board and I think where I ended up will work out ok. I might have to sacrifice a tiny bit of nose rocker. Now I’m just waiting on some stuff from foam ez and trying to figure out wtf to do about the sail box smack in the middle of the shape. I don’t mind it aesthetically, but its going to make it a pain in the ass to take down with the rest of the foam on the deck. I cant think of a way to take it out without destroying the two stringers its wedged in between. Any suggestions would be much appreciated.

the last one I did I just when right over it with the planer slowly. Or you could route it out beforehand bit of a bitch that way though.

[quote="$1"] ...Or you could route it out beforehand bit of a bitch that way though. [/quote]

Maybe not. I could see setting a board on either side, about half inch thick, setting the router depth at 3/4", and routing a clean quarter inch off the top, box and stringers. Then just plane the rest of the board down to meet it.

[quote="$1"]

[quote="$1"] ...Or you could route it out beforehand bit of a bitch that way though. [/quote]

Maybe not. I could see setting a board on either side, about half inch thick, setting the router depth at 3/4", and routing a clean quarter inch off the top, box and stringers. Then just plane the rest of the board down to meet it.

[/quote]

That would be fine was thinking more of a fu box I routed out because some idiot had glued the fin into with the plate still in it.

I guess I wasn't paying close attention - I was thinking about taking it down, he mentioned taking it out, which you were referring to also. I guess I was just thinking of taking it down because that's what I would do. Taking it completely out would be trickier, for sure.

I have found it makes the shaping much easier to remove the box.

On the first few I drilled a series of holes along the bottom of the box, then stuck a fin in the box and broke it away.

On the last one I set the router as deep as possible and it ended up in the box breaking away too. Both mehtods leave a little bit of damage to the stringer and surrounding foam, but nothing that cant be filled with an offcut from the tail that has been lopped off.

Sorry, I only have an ‘after’ photo.

Picked up two boards plus sails fins etc for 50 bucks today.some of the bits will go to my dad. Interesting possibilitys for the fins. Theirs a nasty looking alloy one.

Thinking probably 7’3ish rounded pin single bigger version of a much repaired trigger bros from one not sure on the other yet.

Pics in the double post now ![]()

The thing people throw out aye this ones had a hard time to, also a 6’4" but a winged pin single. Some earlier owner had made repairs with silicon not 100% sure my repairs are any better haha

darnit double post

....good score , mate !

got a shot of the metal fin , too , please ?

Trigger Brothers , eh ?

I had a 6'4 winged swallow singley , which became the 5'11 "prawn' I had for quite a few years here . The trigger's underside was pretty smashed , when I picked it up at the local 'dump' , for 7 bucks ...

So took 30 minutes to remove the glass from the boards then another 30 to get the later of dcell and glass under it off the bottom of one arrgg don’t want to do that again.

Have one mostly shaped filled the holes from the foot straps today used gorilla glue and some of the many pu off cuts.

I will be able to sand them down tomorrow then I need to get some cloth to glass it.

Nice! Can't wait to see it glassed.

Total first-timer here (both Swaylocks and shaping) but thought I'd share my adventure all the same…

[QUOTE=Masterkook;1299964846]So, I promised to give an update on my steps through recycling an old windsurf board into a surfboard…

I started off with a Mistral Diamond Head SST. An old slalom board of 2.95m. I soon found out what the SST stands for: steel stringer technology. Those thorough Swiss stapled a load of steel wires onto the EPS foam. No fun when stripping the skin off the board: the staples tore holes in the foam and the steel wires cut into my hands…

After surveying the damage done to the board, I decided my surfboard needed a stringer. So layed the board down and cut it in half:

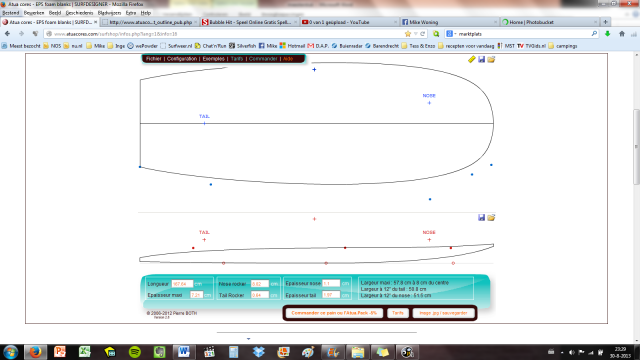

I checked Swaylocks and made up my mind I was going to make a Mini Simmons-like board: lots of volume, wide, short, no rocker. Went to Atua.com and wipped up a shape to work around:

(in the end I changed the outline a little, but pretty much stuck to the rock line).

The foam core was pretty wrecked after I tore the skin off the board, so had to do some repairs and fix some holes. I fixed the holes with EPS foam I bought at the local DIY, that is normally used for isolating roof and such.

(the lady in the shed with heart torn out and in general pathetic shape… at this point in time, I’m seriously doubting wether I can pull this off)

Pre-shaped the stringer and cut it out of thin plywood.

Stuck some glue on both sides of the stringer and clamped the two halves of the core onto the glue. Let it all set for 24 hours or so.

Drew the outline onto the foam but it turned out the core was more damaged than I initially thought causing my outline to touch on some torn out parts. I thought I would be able to compensate later on in the proces (I didn’t realise this would be hell). Managed to forget to get pics of the glued up ‘blank’ (doh!).

Carving the block down to the correct thickness (foil) was a bit of a hassle having only handtools. So I used the saw quite often. It’s hard to keep the profile nice and symmetrical with a saw then shaved the ultra raw deck and bottom profile down a bit.

Then came endless sessions measuring with a level and calipers and touching up whatever part of the board wasn’t ‘flat’. After quite some time whittling away the blank was as good as I was going to make it (and my patience shot) so I called it a day and sawed out the outline.

(still raw but slowly getting there)

Lots of whittling, shaving, sanding, and rasping later, I was happy with the deck and bottom, so put in the rail bands (talk about nerve wracking). One proble I ran into was that I read a lot about rail bands but as I was shooting for a slightly different deck profile (S-deck) I had no idea how to draw the rail bands. In the end I jotted a start line and a few reference points and kind of free handed it.

Lots of sanding later and the blank is starting to look surfboard-ish. 5’6”x 22”x 2.75”, about 5” of tip rocker and 0.25” of tail rocker, light single concave from about mid-board down out the back.

Filling the holes with spackle (allesvuller) now; then another sanding and buffing out session and then it’s time for glassing!

Meanwhile I just heard that my 'real' custom board is ready for glassing too (6'4" Holanda Cruiser)… So stoked about it (as I'm coming off a 'playmobil' NSP)

[/QUOTE]

[/QUOTE]

Cool to see its coming together.