didn’t want to clog Greg Tates great post so I started a new one on a similar topic.

Seems like there’s lots of questions about the stuff

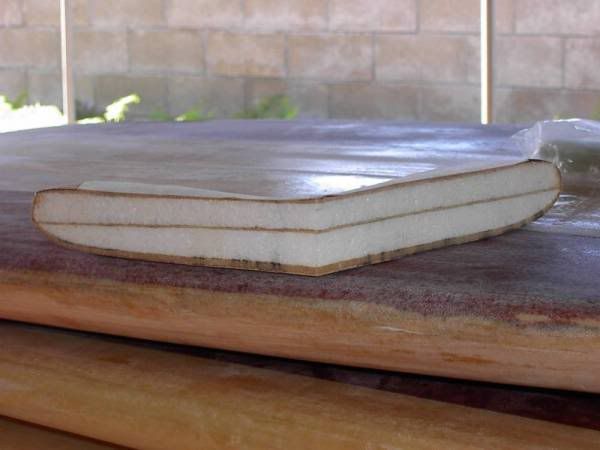

I’ve probably messed around with the stuff more than any regular poster here going back 4-5 years now. First of all here’s some pictures of the stuff we’ve done over the years and then I’ll make my comments on the experience. Pictures are always a good way to start.

Okay here goes

#1 its crap to work with

#2 its hell easier than glueing up strips

#3 its hard as a rock but will still flex ( I once told Brian its nature’s version of carbon fiber)

#4 it will not puncture like glass when banged

#5 equivalent to 1-2 layers of 6oz glass

#6 because of #3 and #4 its prone to delams

#7 because of #3 and #4 its makes one hell of a deck patch versus a glass patch

#8 runs $30-$40 for a 4’x8’ panel enough to do both sides of an 8’ including material for springers

#9 you cut it with tin snips

#10 you need to sand the coating off before laminating it

#11 it will not wrap a rail like balsa

#12 harder to use and thicker than the flat cut bamboo veneer

#13 creates a cross axial bias with the weave especially when sandwiched between two layers of glass

#14 we use 2oz under and 4oz over

#15 its available here in Hawaii at Homedepot, Lowes and City Mill under the brand name Simlopan(sp)

#16 it can be purchased at Franks Cane Supply on the mainland

#17 the best way to do veneers is to bag the entire inner glass+veneer+outer glass on at the same time

#18 we’ve moved on and only use it sparsely nowadays to lock in fin boxes to the blank and as deck patches

#19 if your can figure out how to do it it may make one hell of a thin and easy to mount perimeter stringer I’m suprised the flat veneer folks haven’t thought about this one yet, You can create a super stiff super thin and light perimeter band and then a layer of PU or high density on the outside of it.

Oh yeah you can make one hell of a light and stiff board when you use it as a shell over 1lb EPS. If that’s your thing.

In the end, we now understand that proper design is way more important than materials.

Hope this helps