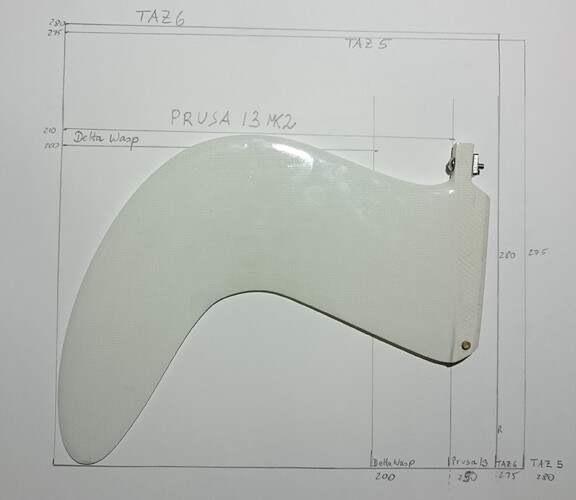

My minimalistic approach to the 3D Tough Fin Base design: One extruded polygon and the rest are all cylinders.

Unfortunately it turns out to be quite expensive to buy a suitable 3D printer, and online printing is surprisingly expensive, too.

It could cost around AU$200.- to print both halves of the split mould, and a suitable printer would cost AU$1300.- .

For now, I’ll try a bit longer to manufacture a near perfect TFB by hand. But it’s only a matter of time before I will cave in and buy a printer.

//194mm x 194mm to allow 3mm thick mould walls on 200 x 200 printer.

difference() {

color("blue",0.1)

translate([-3,-100,-3])

cube([200,200,7.5]); centre=true;

color("red",0.25)

translate([0,97,0]){

rotate([90,0,0]){

linear_extrude (height = 194, centre = false, twist = 0)

polygon(points=[[0,0.05],[0,8.95],[24,9],[24,0]]);

translate([40,8.95,93])

rotate([90,90,0]){

cylinder(h=8.9,r=40);}

translate([80,8.95,80])

rotate([90,90,0]){

cylinder(h=8.9,r=35);}

translate([100,8.95,70])

rotate([90,90,0]){

cylinder(h=8.9,r=35);}

translate([130,8.95,60])

rotate([90,90,0]){

cylinder(h=8.9,r=33);}

translate([160,8.95,60])

rotate([90,90,0]){

cylinder(h=8.9,r=28);}

translate([169,8.95,68])

rotate([90,90,0]){

cylinder(h=8.9,r=25);}

translate([177,8.95,58])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([153,8.95,43])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([153,8.95,75])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([146,8.95,41])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([110,8.95,46])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([120,8.95,83])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([77,8.95,58])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([57,8.95,66])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([70,8.95,106])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([26,8.95,66])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

translate([26,8.95,124])

rotate([90,90,0]){

cylinder(h=8.9,r=15);}

}

}

}