Hey there swaylockians,

I’ve been bored in the uni computer labs today… I know I should have been doing work but my mind inevitably wondered to surfing, surfboards, building no.2. etc. you see the progression? Well after being chuffed to bits with my first board, and having got over any worries I had about Totally messing it up I fancy making a classic old/nu school fish, god knows when, maybe Easter?

One problem I do have though is that many of the fishes I see either have glassed on fins or are quads. I rather fancy knocking up a twin fin, alas glassed on fins aren’t an option as I travel quite a bit with my boards. Ok so that leaves me with the option of which fin system to go with. I quite like the red-x fin system however it seems like it’d be a bit of a ball ache to get it in the uk. Seabase do 6 ¾” boxes, just shorter versions of the usual 10 ½” center fin boxes as far as I can gather. So it would seem its either these, futures or maybe fcs? Not too sure about fcs though, not such a fan. Unfortunately I have had no luck trying to find fins mildly resembling the keel fins I see elsewhere on this site. Well not to fit these systems anyways.

Trust me this is going somewhere.

Basically after talking to one of the technicians, they have given me the go ahead to knock up some fin templates and use some of the more complex cnc machines to make my dreams reality. Isn’t it great doing engineering?

Well this is what I’ve come up with so far, tried to address some issues I can see though I think it’ll take a more experienced eye than mine to help refine these into workable designs!

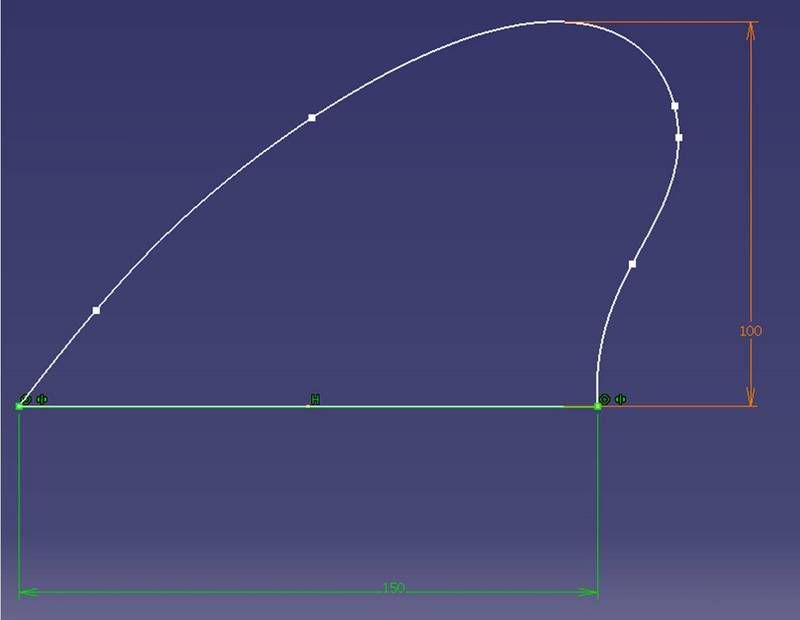

The fin template:

This is just a quick sketch off the top of my head; dimensions are in mm, can change this shape substantially if needs be.

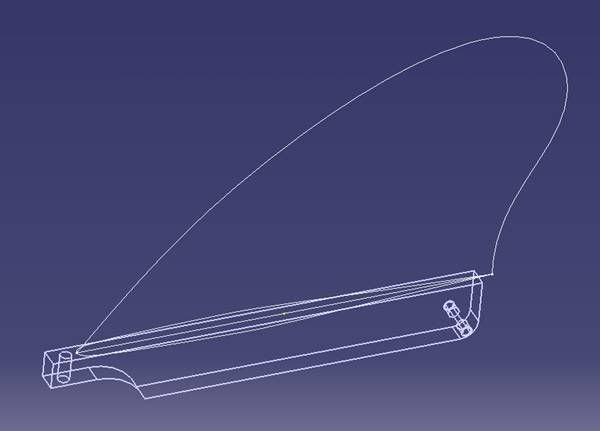

For the standard box:

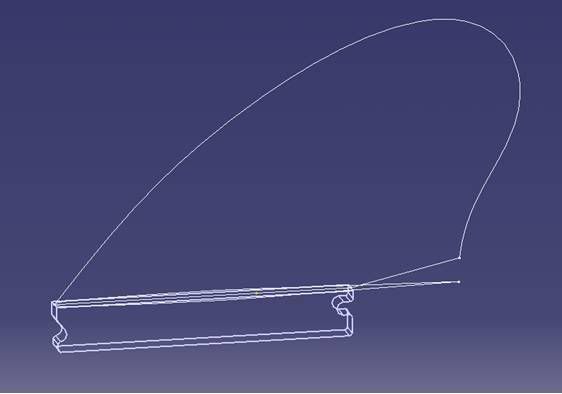

Futures fin system

I have taken an angles section off the back of the fin so you can locate the rear slot into the box due to the extra length. Ignore the foil line. Would this have a substantial impact on the fin? I’m thinking it’d make it flex at the back, maybe slow it down?

Using the fcs system would get round this problem

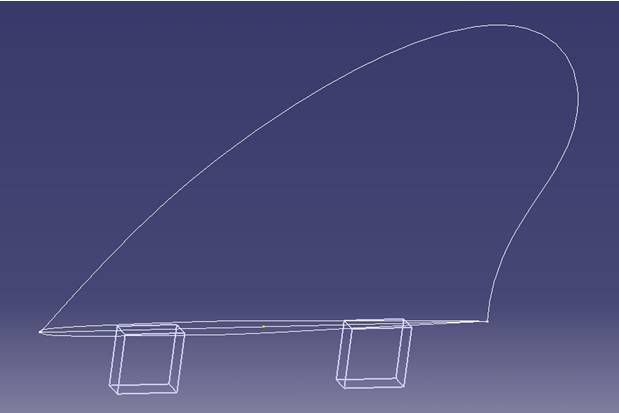

I don’t have the correct dimensions for the fcs tabs, anyone care to enlighten me?

I havent put a foil on these fins yet, though i was thinking that much the easiest way would be to do a simple curves surface wither side then fine tune this by hand sanding.

I also thought about cutting the ends off two futures boxes and sticking them end to end to make a longer box? Innovative? Or just foolish. Shouldn’t be too hard if you can keep them straight while setting.

Anyways any thoughts are, as always, much appreciated

T