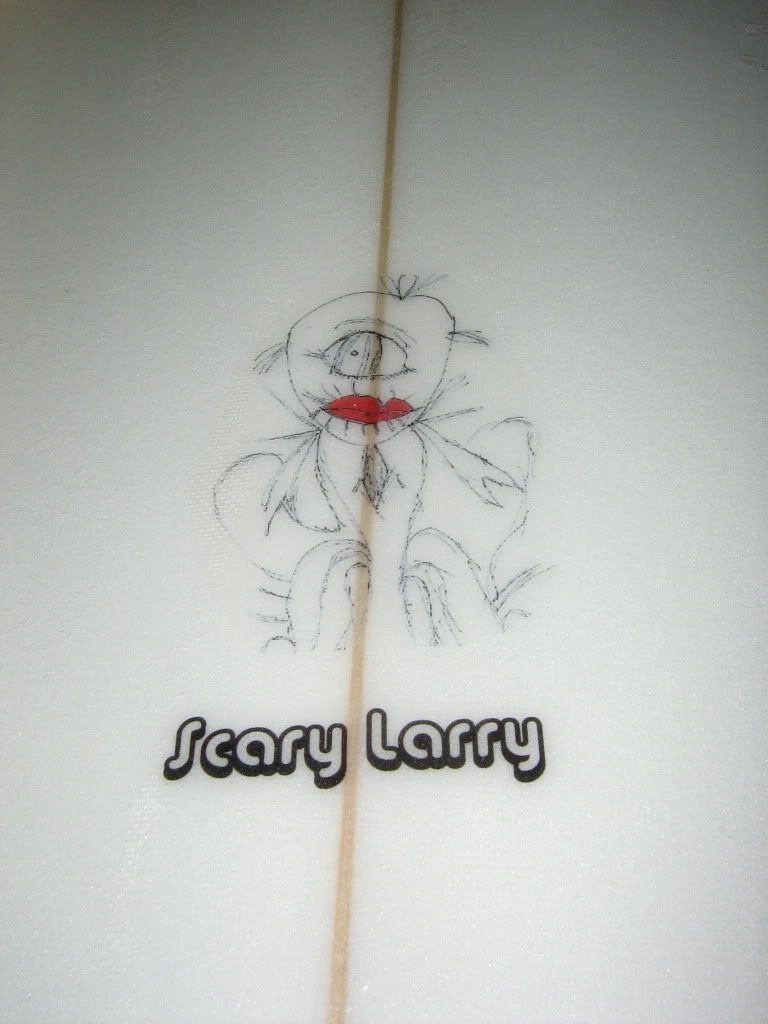

So I recently finished my first board (shaped and glassed) and was searching for a thread to showcase the first timers. Unless I missed this thread, I couldn’t find it. So I’m going to try and start the “first board thread” thread. No real rules, just start posting. While this is actually my second board, I’m considering this my first since I only shaped the first and asked a pro to glass and finish the rest. Also, my first board didn’t require a template. It was ready to go, just needed to sand it and put in the rails. So I feel like this is my real “first” board since I made a template, cut out the shape from the blank, shaped, glassed, hot coat, sanded and put in the finbox. So here it is, my first board: Scary Larry. I made a template from my first longboard and quickly learned the importance of having a good template. First time using a planer on this one and that was an interesting learning curve. The glassing was the toughest step. I used 6+4 on both top and bottom and an additional 4 oz Volan on the top. Wanted to cut the Volan to match the outline of the board but quickly learned that fiberglass cloth is not the easiest to cut in large shapes with rounded edges. Also encountered some air bubbles in the edge. I think trying to glass in a garage was also a frustration; stepping in resin, limited space, dog hair and other particles in the resin, etc. Should have taken more time sanding down the laps. Sanded down the laps on the bottom but didn’t on the deck. Now I know why I should have. Need to learn tha art of pin striping but for now, the art of waxing the deck will do. Hot coat was a breath of relief compared to the lam process but ended up with more paint brush bristles in the hot coat than I liked. Finbox install was pretty smooth but grinding down the finbox wasn’t as easy as I thought it would be. Sanded down the bottom of the board and learned a lot. Left the deck as as is due to fear of hitting the weave (from not sanding down my laps). The Scary Larry logo came from my daughter when she was six. Simply scanned Scary Larry into the computer and printed it on rice paper. Used MS Paint to just color in the red lips. Surfed it this weekend and was pleasantly surprised. Tracks straight, paddles well and stills turn (left and right). Thanks for all the help from on this site and I’m fired up to do another board.

And for all you other first timers with the less than perfect first board, please post your experiences and pics!