I posted up in the What I’m Working On thread, but I’d rather not clutter that thread with constant updates. So I’ll start my own. Comments are always appreciated, and I hope it will serve as a guide for anyone else starting to build in their garage. I’m also shaping the whole thing by hand (no electric planer).

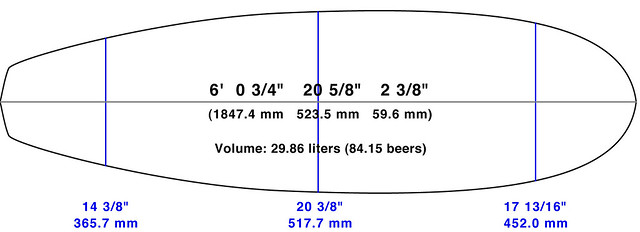

I printed it out and taped up the pieces of paper. Took 5 sheets of 11x17. I printed each sheet with a border to line up the pages. Without the border, it’s hard to keep the pages straight with just the board outline.

I traced straight from the paper. I probably should have traced to masonite, cleaned it up, then traced to the board, but I didn’t have masonite and I don’t even know if I’ll like the template enough to wanna keep it. Tracing from the paper wasn’t too bad, and I’d end up cleaning up the outline with a sanding block any ways, so I didn’t think it needed to be perfect.

I traced the template on the deck (didn’t know any better) and was quickly corrected by a forum member. He some great points about why I should trace and cut from the bottom. I also wanted to re-do the template and pull in the tail a little, so I did it on the bottom.

Tools. Marked my nose, tail and wide point and aligned my template. I ended up grabbing an EZ- Square Pro from Foam-EZ after dealing with a square and ruler. The square and ruler work fine, but it’s not nearly as simple to deal with. Slapping the EZ Square Pro down is so much simpler, and leaves much less room for error.

I cut it out with a saw, and left like an inch of buffer around the outline. I’ve only worked with EPS before, so I wanted some foam to play with before getting to the outline. Then I used a soft sanding block and 40 grit to get to the outline. Then 80 grit to fine tune and square my rails. The softfoam block was kind of difficult to keep square, so I wrapped some 120 grit around a wood block to square up my rails. Worked well for me.

Here’s my outline as of now. Once I smoothed the outline and did my best to clean up the highs and lows, I skinned the bottom with a block plane.

I started at the stringer and worked my way out toward the rails. It cut fairly smooth, but near the rails it got a little chunky. I suppose it won’t matter much, since I"ll be shaping all that foam away when I work the rails and thin out the volume of the board.

So that’s where I stand now. The blank I got was a second from Foam-EZ, so it has a bubble hole on the bottom. They told me to fill it with some extra light drywall spackle and distilled water to thin it. I was thinking of filling it tonight before going farther. Would you guys recommend filling before shaping? Or fill before glassing? Also, the hole has some skin on it, should I route it out? Or will it be ok to just pour the spackle in there?

Also, this is what happens when I’m too lazy to move my bikes out of the shaping area before sanding. Doh!