I thought i would share a little bit of my work i have been messing around with. I enjoy making my own fins, but never came up with a better way of producing the bases for them. All of my boards are lokbox, so being able to switch out a multitude of fins will be great.

I have to apolgize for some of the how to parts of this thread, i forget about the camera half the time, so there are some gaps.

First off the Molds.

I made some simple forms with paint stir sticks (free at your nearest walmart), and joined em up with hotglue. I prepared the existing fin with a light coating of vasiline as the release. I used a normal wall plaster compound that also has a cellulose addtitive that stops cracking and chipping.

I also repeated the same steps for a standard fins unlimited box. This took a little more time to make sure the plaster completly filled the form without any voids.

Both boxes pulled right out after letting the plaster set with little cracking. Some seperation did occur around a few sides of the forms. I just filled those viods up with hot glue and hoping for the best.

Next up is the bamboo fins via Greenlight Surf Supply.

Finished foiling and base tabs sanded down

I have never had good results with laying up fins by hand, and getting the glass to wrap to the contours so i thought dropping them in a bag would work just as well.

Preparing for the vac bag…

From the bottom, i have wax paper, fiberglass layer, fins, fiberglass, wax paper. I then tape the two ends up with masking tape so things don’t move, and wrap a strip of breather all around the “package”.

The whole set up looks very similar to this, and used here is a huge ziploc bag. (If you haven’t figured it out yet, im trying to keep things cheap on a student budget)

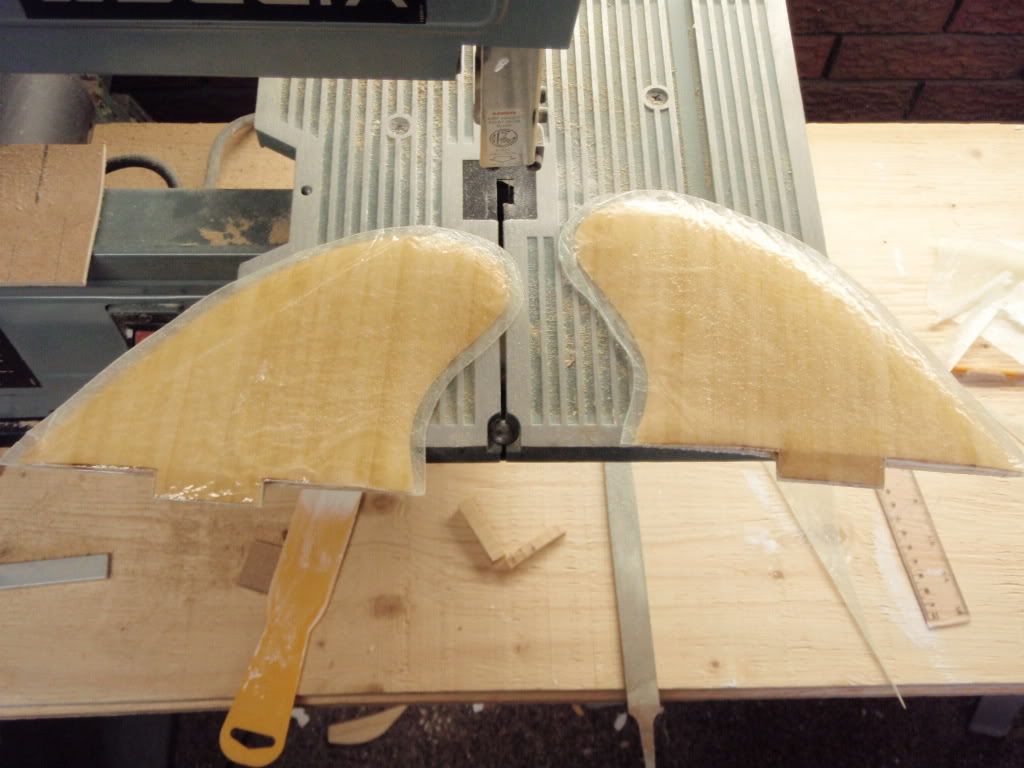

Here are the Bamboo fins out of the bag, and rough cut out.

Here are a set of quad fins for a 9’6" longboard that are right out of the bag.

Finally, here is a picture of the vac setup i built via joe woodworker. Works great and is pulling down a laminated skateboard at 20 mmHg.

Right now, im waiting on a hotcoat layer to dry on the fins and will post some pics of the molding process when i get some time.

Have a good christmas eveyrone!