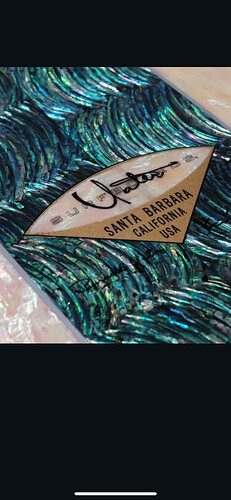

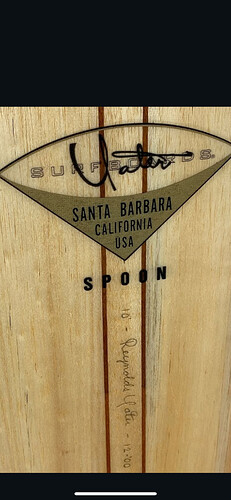

I just came across some gold and copper leaf sheets that I’m thinking would be cool to implement into my logo, like the old Yater logo’s pictured.

Does anyone know how to go about this?

The Yater laminate logos were “Screen” printed. So they were done on a Silk Screen press using ink. Not Gold Leaf. If you were to apply Gold Leaf to a board it would be done during the lamination/fiberglassing of the foam or wood surfboard blank. You would need to design and make an emblem that could be applied under the glass. A one off made from paper backed wood veneer or a cut out and painted hand drawn poster board is where I would start. Kevin Ancell did the Abalone and “Mother of Pearl” that was applied to the Yater board in your pic. He is a highly respected and acclaimed artist. Of course Reynolds Yater(retired) is no less an artist. Just different forms that happened to compliment each other.

The logo in my avatar has Speedball water-based metallic silver printing ink on heavy rice (mullberry) paper. The white background was screen printed first, followed by the silver and black, dried between each color.

do you think it would be possible to use a gold foil under resin? i feel like bonding might be an issue, but I saw Randy had a Phil Edward’s Hobie with a “foil logo” as he said

The issue would be the “surface energy” of the gold leaf/foil.

If it is metal-based, my recollection is that epoxy bonds well with metal. Just be sure not to get hand/skin oils on it.

Do a test panel and peel the glass of the panel. See if the gold leaf lam pulls loose with the glass.

Some sort of test with actual materials would be best.

I am currently building an epoxy-covered table for work and have a sample board with the pigments and clears being used as well as various graphics that are supposed to end up under the clear epoxy.

My recollection of gold leaf is that an adhesive is applied in the shape of the design and then the leaf material on its backer is applied and the leaf transfers to the new adhesive. Once the adhesive is set, whatever else is done like ball turning, pin striping, etc. I have to imagine it gets buried in clear coat as well. Perhaps you have searched and read this all already. Having all that work buried under gloss coat resin might be OK, under fiberglass cloth…there will probably be a loss in clarity, shine, etc. which would make all the effort seem less productive.

I am not Randy , this is what I found looking for that ‘foil’ logo online:

Yes that’s the logo I was referring to, I will make a few and do some tests, leave some in the sun for a few weeks and see what happens.

I will try to report back with any updates

The material used to make party balloons (metalized polyester film) might be worth a try. Sometimes it is challenging to get inks to stick to bare film.

There are also the Cricut-type cutters that are meant to cut adhesive backed films, and those come in all kinds of colors and foils. The places that cut out vinyl lettering for boats might be a place for tips or perhaps even some scraps to try.

I could be wrong.

But I have a vague recollection that somebody somewhere used vinyl for vac-bags/bagging.

i used gold leaves on a few boards…

the below was done with the black part printed on rice paper under the lam and after fill coat was sanded, i added the gold by painting water based size on applying the gold leaf (real gold, no plastic-y one)

with an epoxy gloss coat over everything.

to see the process in details on another board:

look at 13:30 in the video below.

So does the “gold leaf” make that board surf any better?? Cause if it does I’m gonna melt down some of my gold bars. Oh my bad; It’s not a surfboard.

around 11% faster ![]() … and yes, when living in a country without wave, one has to adapt the board making to the available conditions.

… and yes, when living in a country without wave, one has to adapt the board making to the available conditions.

Got my first big professional job decades ago.

Been landlocked ever since.

I still make Surfcraft and ride what/when/where the opportunity presents.