wait how did you get it so… GOOD and smooth with out sanding or polish?

skiny, What do you mean, the top of the board? Well it was sanded the same as the bottom before spraying the 2 part urethane… After spraying the urethane there is really no need to sand or polish. Thats just the way I have allways sprayed finishes on furniture and cabinets. I do know I am one of the few furniture makers that has taken the time to learn to spray polyurethane varnish. No, it’s not easy to learn polyurethane spraying . But aftere I figured it all out it is now easy. As far as spraying 2 part auto urethanes its very easy if you use the right speed hardener and are set up to spray. I don’t, know I guess I’ve been building cabinets and furniture for so long that I don’t much think about it , I just do it. I made a coment about everyone has trouble with fish I but I never have . I guess that’s because I learned to finish at an early age from guys that knew their stuff. I haven’t done much brush finishing since 1985 when it became impossible to get Russian Pig bristle brushes. I tried Camel hair for a while. They dont make good brushes anymore so I don’t bother. Just one coment on finishing epoxy. I use West systems epoxy and it is recomended that it be finished with a top coat of some kind of varnish and I kind of think they know their stuff because they have been around a long time. I understand that some other resins are formulated for surfboard use so maybe they polish out. I don’t know, haven’t tried them . Aloha Wood_Ogre

i really am in awe of you workmanship. just spectacular. i hope you can post pics of your board in action one day in the future.

also, i look forward to you sharing more of your work on swaylocks.

i may never build a HWS, but i like watching people work with their hands.

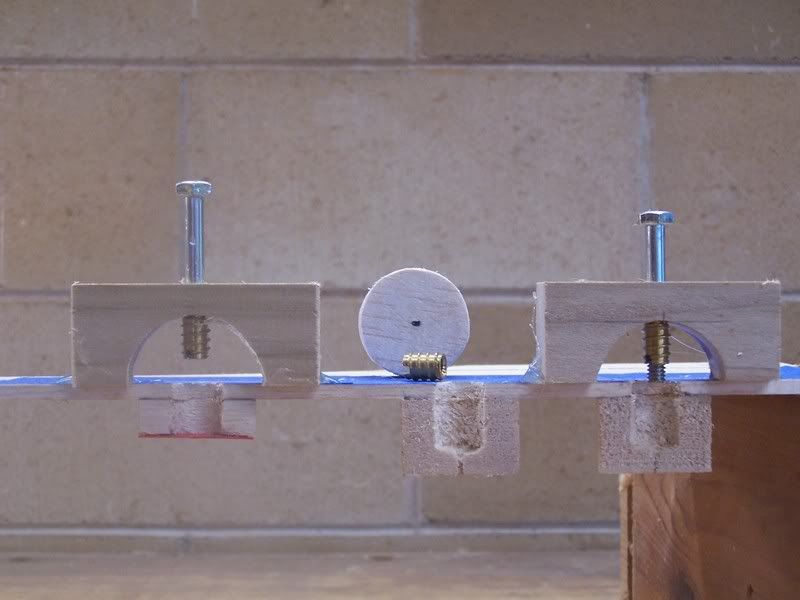

For those that asked about the vent inserts! I did a cut away so you can see how they go in the board. The left shows the vent insert and right is a foot strap insert. The jigs are hot melted to masking tape and the locator bolts are waxed so the resin dose not stick. The vent insert has some red plastic glued to the bottom of the hole to hold the resin and after it is dry the hole is completed by drilling through the insert hole into the inside of the board. The bolts are pulled up so the resin can be put in and then pushed down into the wet resin. After the resin is hard the jigs and tape are removed and the holes are re taped and filled to the top.

Here is the finished board with the footstraps installed the top was not polished and the wax sticks to it real good.

The bottom is polished and I put in the FCS fins to start and will try other fins too. Have not had a chance to do a good test drive yet. No wind ! So will post again as soon as!! Aloha, Wood_Ogre

Dang Wood Ogre!

Talk about going above and beyond to explain a concept. Makes perfect sense how (and why from previous posts) you’re doing it that way. Thank you! If/when my vent leaks I’ve got a good idea how to re-do it. The finished board looks really good, hope you get some wind soon.

Pat

Hi Wood_ogre

This is a great thread. I have learnt sooo much. Please excuse my ignorant question but I am busy building my first board and this is my first woodwork project! How do you locate the wooden inserts on the under side of your deck to drill the holes in after the deck is glued on and glassed? Is it merely done by remembering the measurements of where they were placed or is there some clever trick?

Thanks

Antman

Top stuff ogre, great thread and a beautiful board.

Make sure you post how it rides, is that fin set up how you going to ride it?

Excuse my kiteboarding ignorance but the fin cluster looks the wrong way around. Whats the go?

Have fun, I know you will.

Antman. First you have all your fin and insert locations marked out on your master template. Then after the top deck is glued to the frames you mark the location of all the inserts on the top of the deck useing the master template. Then you drill a 1/16 inch hole in the deck at the center of each insert. That becomes the reference point on the inside of the board and you can line up the plugs on the inside of the deck with this hole . When you are ready to drill the holes you just center on the small hole in the deck and with a depth mark on your drill bit drill. Easy! I hope that is clear enough.

Barb, Yes the fin set up is backwards of a surf board. Why? Because a kite surboard has the kite trying to pull it down wind and you also have lift from the kite so it’s a different animal. Think racing sail boats here. You need a fin keel to go to windward! You don’t have much bite with the rails as they are to fat, thats why the bi directional boards go to windward so well. They have a very thin rail and you sail on the rail and don’t need much fin. The Kite Surf board has a fat rail that dosen’t bite into the water so you need fins. Only fins in the back and you still end up sailing sideways. Taking a lesson from racing sail boats I put the center keel fin forward and the weight of my back foot is directly on top of the fin keel so I have something to bite into the water to keep me going to windward .The two side fins help but they are the guys that do the work when it comes time to turn. Surfboards think light and flexible !. A kite surfboard has a lot of horse power and is going fast and needs weight to cut through the chop and keep it from pounding. Dose not need to be flexible as the rail lenth is short enough to carve turns or you can pivot off the back fins. Does it work? I will know soon. Aloha Wood_Ogre

Hola,

Again talking about the footstrap insert theme.

I’m afraid you made the same error I made lots of times before.

It’s not the bolt who twists inside the brass nut if you screw it tight.

It’s not the brass nut who twists inside the resin cilynder if you screw it tight.

It’s the resin cilynder who twists inside the wood hole if you screw the footstrap bolts too tight. It’s due to its round walls. The resin cilynder offers nothing but surface traction to avoid twisting.

Some boards came to me with those resin cilynders completely dettached from the board.

I came to a solution by making a rectangular hole into the foam (in my cases). The flat surfaces of the resin “cube” offer a lot better opposition to twisting.

I hope wood have better traction then PU or EPS foam and you won’t have this problem.

Ahhhh. So simple.

Thanks.

neira, No I did not make a mistake on the inserts. You are thinking very much like a foam board builder! Yes a retangular hole would give you more surface area on the side grain. Balsa wood is not foam. If you take out a plug and check out the penitration into the balsa you would see how much resin penitrates the balsa. In a foam board we would put in a large balsa block and then do the insert as I show. Been doing it in windsurf boards for over 20 years. Want more information on pull strength and twist strength in different materials, West Systems Epoxy has allready done the tests. You can find this information in Epoxy Works. And to go one better US Forest labs have also done the tests as has Wood magazine. In your case the foam is the weak link. IN fact West systems actually has a size chart someplace for sizing holes for different size bolts. If you drill out a hole in balsa with a forstener bit you will end up with a very eliptical hole and not a round hole.Try it and see. Aloha ,Wood_Ogre

Interested to know how that fin set up worked out for you. I loved the thread, just wondering if you got a chanse to ride it yet.

Wood_Ogre,

I have to tell you how much I appreciate someone with your experience, and knowledge, being onboard and contributing here on the Swaylocks forum. You are a real asset. Like many others, I have learned some valuable techniques from this thread. Thank you.

Bill Thrailkill, I am humbled by your compliment. Thank you! When were you shapeing for Velzy? I have my first surfboard that I bought in 1965 which is a Velzy (surfboard of champions) The last time it was surfed was in August 1967 a couple week before I went in the military. Since then it was stashed in my dads garage up in the rafters. About 1995 my dad sold out and retired to Hawaii. He brought the board to me and I have it in my wood shed and am planning to make a hallow wood copy of it next year. I am amazed that he sold everything he owned and yet kept this old board for me. I have always admired surfboard shapers and always wanted to be one but thought it would be a good way to stay poor. I manage to stay poor enough as a cabinet, furniture maker! Anyway after finishing my Hallow fish I relized that maybe I was good enough to walk with the great Shapers of the world. Dick Brewer and Ben Aipa have been my shapers over the years but now guess I will just make my own boards. That way I can play around with all the ideas that I could never get them to do. Aloha Wood_Ogre

Wood_Ogre,

I shaped for Velzy in 1960, shortly after the Velzy/Jacobs split. Dale opened a total of five shops after the split. I shaped in the San Diego shop, with Del Cannon. Within six months the IRS landed on Dale with both feet, closed everything, and sold all the assets, including the Velzy name, to pay taxes. This was also the period when Dale was driving a 300 SL Gullwing Mercedes. That went too. Keep us (Swaylocks) posted on your future projects. Aloha.

Keen, Since I finished this board the weather conditions have not been condusive for kite surfing. We have had good surf but no wind. I have had it in the water twice one time for twenty minutes and yesterday for about 40 minutes, No waves. All the guys that said hallow wood boards are different were right. They do feel heavy out of the water and they float high when in the water. I was very impressed with the board! It is very responsive and very fast and holds speed in the jibes without stalling making for some big round house high speed turns. I used the FCS fins and had expected to be able to spin them out,but couldn’t. What I found strange,and something I have never experienced before, is that I can pivot the board on the center fin. I am thinking that maybe if I moved that fin up I would be able to spin the board in a 360. Seems to go to windward much beter than my other comp boards. I do know that I will not go back to using my comp boards anymore. There is so much to experiment here that I am going to continue with the hallow boards. The next one will be a little shorter. I had guessed that the fish had a lot of potential for kite surfing and I was right. Now all I need is wind and waves at the same time !! I am looking forward to a lot of fun!!

Here is the fin set up I am using now. I have also made some keels and a couple other fins but want to get some time in with these first.

Aloha Wood_Ogre