Howzit Ogre, First off in my mind you haven’t screwed anything up, you are just trying to help so no appoligies needed. Sorry to hear about your wife and kids, I am just getting over the same ailment which hit me last Saturday after getting home from judging the Volcom contest at Pine Trees. Still having some stuffiness in my head but feeling much better. Well now that you say we have met I have to wonder when and where. I came to Kauai in early 73 after 3 years on Oahu so it sounds like we’ve been in Hawaii for about the time, and yes we have seen lots of changes over the years. I agree The Bay is a whole different place since it seems that all the people who have bought property seem to think they got a spot in the line up also which has turned it into some what of a circus and they even try having an attitude towards the boys who have been there for years and years. Well I hope we meet again some time and you won’t be forgotten by any means. Aloha,Kokua

I’m no local at any spot but my home break is cb and it pisses me off how some people that i know are not locals just feel the need to drop in on me or just show no repsect for any one or anything.

ogre what are some simple ways to get rid of fish eye?

p.s. hope your family feels better woodogre

Skiny, Check the shellac thread. Aloha Wood_Ogre

Back again. Got the glass laminated. This is the first time I have done a lam with West 207 hardener. The 206 has always been easy. This 207 is a lot thicker and a lot more work and it goes off faster. I wasn’t satisfied with it. Got to many shiners but no air or anything. Had a frightmare. I was two thirds up the bottom when the neighbor descided to mow his lawn with his riding lawnmore. Before I could run up and stop him I had all kinds of bugs and junk floating on my resin. What to do? Well, I descided to pick off what I could and just leave the rest . Well the bugs are now fossils in my glass job.! Oh well! When I flipped the board and did the top things went somewhat better. Didn’ take any pictures of the glassing. Didn’t want to resin up the camera.

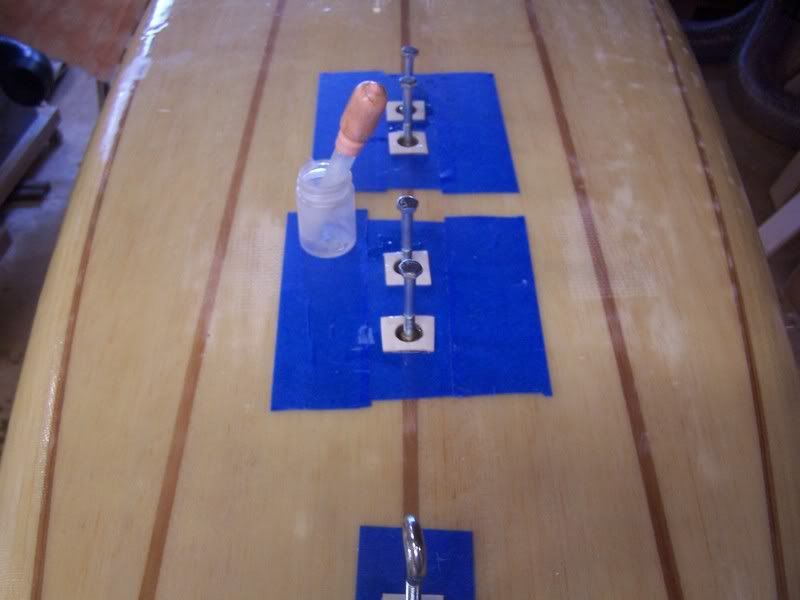

done with that I drilled the holes for all my foot strap inserts, vent and leash insert too.

Taped around holes then assembled bolts,jigs,and inserts. Centered inserts in holes then hot glued the jigs to tape. Pulled up bolts and filled holes 1/3 with resin mix. pushed the bolts back down so the inserts are in the resin.

After the resin set I unscrewed the bolts , took off the jigs and tape. Re-taped the holes. And put on resin dams. put the waxed bolts back in the inserts and filled the holes to the top with resin.

Wood-ogre

Keep it comming, I have learnt heaps from you posting and pictures, excellant way of doing the inserts… The jigs for doing the rails great.

I am hearing you about the bugs, doing my lam last night in probally too humid weather i had a board full of midges (sandflys) brushed most of them out and remembered to shut the door…

Thanks for sharing…

cheers

Hi Ogre,

I really can’t believe that your balsa was still a tree in July and now a surfboard in November. From harvesting-milling-shaping-glassing, this must be one of the greenest boards out there. Considering that there was not alot of used up materials to process your board. Truly amazing and inspiring.

Rio

Drilled out the holes for the FCS. The hole saw bit I have is a little bit to big but good enough. The inserts where put on the wood jigs. I did a dry test and when I was sure every thing was OK I filled the holes about 1/3 with resin. Put the inserts into the holes. used clamps to hold them in alighnment and used a couple wedjes under the clamps to adjust the angles. When the resin had set took the jigs off.Re-taped the holes and used some 1/16 inch balsa with holes drilled in it for dams. Sprayed the dams with 3M adhesive and stuck them down to the tape. Filled the hole to the top with resin. The reason for glueing to the tape is the tape is easy to remove and does not contaminate the surface in anyway.

Very nice work…but,

I do some sailboard ding repair from time to time, including the adding (not replacing) of footstrap inserts.

I had bad experiences when filling cilyndric holes with resin+milled glass for that kind of footstraps inserts. It seems a good idea till you screw the bolt tight to hold the footstrap in place: you screw it too hard and the resin cilyder loose traction and starts to turn in its place.

It’s a lot better to route 1 rectangular hole for 2 bolts than 2 cilyndrical holes for 1 bolt each.

It’s a lot better to route 1 rectangular hole for 1 bolts than 1 cilyndrical holes for 1 bolt.

I hope it helps.

Hey Orge.

have you tried a quad setup for kiting, I have heard its a good fin set up as it gets the fin out on the rail. sounds good in theory.

looking foward to seeing it done and hearing how it stands up to kiting abuse…

cheers

Howzit Ogre, I see you have installed 3 pluge per side, Are you going to use the wooden FCS keel fins? Aloha,Kokua

Thanks. These brass insert have a groove in them that fills with resin so they wont turn. I have had five or six wind surf boards that were polyester glassed and had same inserts and had one twist out. You shouldn’t be over tightening anyway. Put a drop of Locktight on the bolt snug it down and let it dry.I wounder if using milled glass in insert holes is a hold over from polyester days? From my research in Epoxy Works I think it is not needed with epoxies. Have never seen an insert pull out of an epoxy board. In your picture is the orange color an insert or the resin around an insert? I have seen comercial inserts that are rectangular with two screw and one screw, They are molded out of the same stuff as fin boxes and even thought about buying them.(The threads sometimes strip out). Anyway I went with what works for me and I allready have these brass inserts in my shop. Polyester resin has a shrinkage of 7% , brass is close to 0, so the brass and Poly will fail.Poly is not a good adhesive. Brass 0, Epoxy less then 2% shrinkage and epoxy has an excelent bond to brass. So time will tell. Ill test it out and if they fail Ill let you know. Aloha Wood_Ogre

Kokua , There are three per side. The fin or keel combonations I will be trying are many. They will be made from glass and resin. I can all so use a combo of standard FCS fins and experiment with splitters in front of the fins. If it looks like the out side fins are a bit to far in from the rail that is intentional as I want to experiment with rail fins. I will hot melt them on for expermenting and if I find they work then I will put inserts on the rail or glass them on. I have never much been satisfied with fin set up for Kite surf board. The Wind surf guys did a lot with fins and I think I can take some from wind surfing and surfing and use it on my fish. Dosen’t make any difference if my ideas work just as long as I am having fun playing. My best friend from kid days is an Engineer and he figures out all kinds of things on his computer programs. Most of what he dose never work. I do it just by what looks kool so at least I have an excuse if it dosen’t work. If this project is a flop Im sure the board is still a good wall hanger. Aloha, Wood_Ogre

Hola “Ogro del bosque”,

The orange areas in my picture are resin filled holes.

From your pics and explanation I thought you pretend to screw the bolts directly to the resin.

When I said that overtightening is the cause of failure I meant that the resin is what dettaches from the surrounding material (foam or wood, in your case) and both bolt and resin cilynder turn together.

But now you say there is a brass nut sunk into the resin??

So the bolts pass through the resin but are directly attached to that brass nuts, aren’t they??

OK, that’s another method.

it has been GREAT so far , and THIS is the part I am looking forward to even more …

" Kokua , There are three per side. The fin or keel combinations I will be trying are many. They will be made from glass and resin. I can also use a combo of standard FCS fins and experiment with splitters in front of the fins. If it looks like the outside fins are a bit too far in from the rail that is intentional as I want to experiment with rail fins. I will hot melt them on for expermenting and if I find they work then I will put inserts on the rail or glass them on. I have never much been satisfied with fin set up for Kite surf board. The Wind surf guys did a lot with fins and I think I can take some from wind surfing and surfing and use it on my fish. Doesn’t make any difference if my ideas work just as long as I am having fun playing."

[that last sentence is worthy as a signature , too, I reckon !!]

cheers

ben

Rough sanded and washed board real good. Aftere it was good and dry took my heat gun to it a couple times and was ready for fill coat. Mixed up the 207 hardener and went to it. Fill coat was was easy. Aftere the top was dry enough turned it and did the bottom.

fill coat

Over night and I was ready to sand the fill coat. Started out with 60 grit 3X dry.power sand.Good side lighting and as soon as all the shiners were gone switched to 100 grit by hand and only lenthwise and then 150 by hand. Easy sanding job. This 207 hardener sands better than anything I have ever done.No clogged paper at all. A lot easier than any wood finishes I have ever done and much faster then Poly. Took the board out and washed it down with water and a green pad and then hung it up to dry aftere wipeing with a old well used white towel. Then made sure it was good and dry with my blow dryer. Now the fun part. I descided to use a two part clear Urethane. OMNI MC 161 High Solids with 168 Slow Hardener. This is the stuff the car shops use here on Kauai and I have used it from time to time in some special wood working projects. Another reason I used it is because I had a quart in the back of my paint locker, left over from a job 4 years ago.Love shooting this stuff! It is so easy and so fast. I use an HVLP gun so there is allmost no over spray. My eyeball told me I needed about 180 ml.(3/4 cup) . This is where many years of spraying is helpful ,I can get it darn close on any job just by eye ball. Did the spraying in the lait afterenoon when it was cooling down. Heated the board up good with my heat gun then mixed up the Urethane. Shoot, wait 5 minutes,shoot again,wait shoot again. 6 times. Clean up and finished for the day.

Hung out for finishing

How to hang a fish

So now its finishing time. Dry sanded 100 grit 3x by machine. Hand sanded with 150 3x length of board then took it outside to my special sanding table. Sanded 220 wet, 400wet,600wet,1000wet,1500wet. wash off well between grits. Then dry with soft towel. Rubbed out with Turtle wax Heavy duty Rubbing compound . Then finished with Turtle wax Polishing compound.

Wet sanding

completed polished board bottom

One more wet sanding picture

Top of board not sanded or polished. Off the gun finish will hold wax well.

Aloha Wood_Ogre

A-M-A-Z-I-N-G!!!

What a beatiful work!!

I hope it works both as a kiteboard and as a surfboard.

Any chance of knowing final weight before any gear (pads+footstraps)???