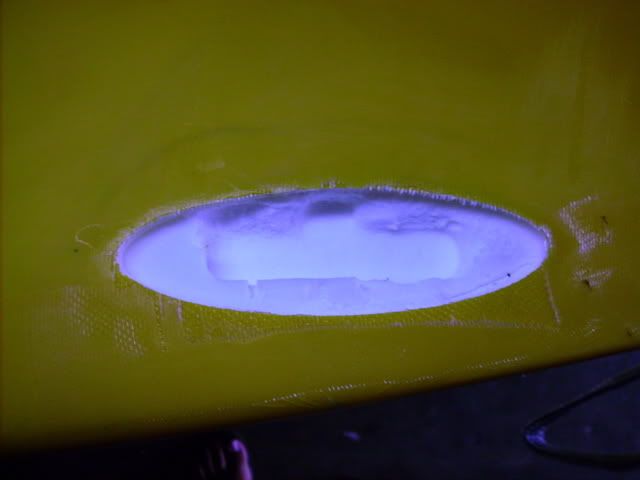

can anyone help me on how to replace the box i have no experience with lok box…just only surfing on it.

thanks in advance

can anyone help me on how to replace the box i have no experience with lok box…just only surfing on it.

thanks in advance

I’m sure everyone here may attack that project in their own way,

My way would probly be the wrong way so lets wait for a repair professional to chime in.

The big question is, Did you get the license plate # of the truck that hit it?

PS do you know Britt Clamp? he’s an I.B. surf cat.

Get one of those yellow cant mesureers and measure the cant on your other fin. Pour resin in the hole and pop box back in making sure you get the cant right. Be careful with your fin and box so not to get resin in or on it. Sand surrounding area and tape off the hole before you lay down a couple of oval or whatever shape you like layers of fiberglass. Feather glass hotcoat and sand. Remember hotcoat fixes everything.

Kensurf, I’d be happy to repair that for you properly. Please PM me your # and I’ll arrange to meet you and pick the board up. Should take about 3 days. Your in huntington correct? Thanks Jim

Nice one, JJR.

How would we repair that properly though? If ya have a minute…

g

I’d rout the hole about 1" deep, then make a foam insert that fit perfectly in the hole(press fit) and re-rout like a first time install. This way you use the same amount of resin to re-install the new box without worries of overheating resin due to large cavities left from the box blowout. Also the overall strength of your repair will just as good as the first box was. You can’t just fill the voids up with cabosil/q-cell it’ll just get too hot and possibly crack unless you set it off super slow. I make the insert by turning a box upside down on top of a piece of foam minimum 1" thick ,then use the box as a pattern. After you make your pencil line around the box you can cut your piece of foam insert down to just at the pencil line (slightly oversized) so it presses in. Sand any raised portion flat. This way when you re-rout it your insert isn’t flying around due to the router bit. Mark 1/2" in from each end right at dead center of the hole, and line up your jig with the center line on the target. After routing remove your insert with your 2 index fingers carefully so you don’t tear it apart, then coat the hole thoroughly with lam resin, insert your insert, coat that, then install the box. Sounds complicated, but with the help of some suncure powder and few drops of catalyst for under the box, I can do them fairly fast, once I actually get to them. Cheers

cheers, JJR, cheers and applause.

yeah kensurf i know britt clamp is i just dont know him too well hah. and believe it or not the fin box ripped out naturally from surfing…wierd.

and thanks everyone for the replies

im pretty sure ive seen you walking around IB with that board. did you get it fixed yet?

It may have come out just surfing, but there was either some (unnoticed) damage from an earlier impact, or the glass was stripped off during the sanding process…or both. Knowing who glasses the OP boards the latter wouldn’t suprise me at all.

you probably have. thats my main board for most of the summer. if i’m not alone im surfing with my best friend thomas who used to be hard to miss before he cut his dreadlocks off.

and im still working on the board i got started on it yesterday, now i just got to put some hot coat resin on it and sand it

yeah it might from unnoticed damage from a while back or the way OP had sanded the board. but i really didnt see any cracks on the glass when i looked at it that morning. hell it could have happend when i was in the water that morning as well.

before i got that board i didnt even know OP made boards hah. i got it 2 years ago in a raffel at a surf competition here in IB(lucky me)

I’d rout the hole about 1" deep, then make a foam insert that fit perfectly in the hole(press fit) and re-rout like a first time install. This way you use the same amount of resin to re-install the new box without worries of overheating resin due to large cavities left from the box blowout. Also the overall strength of your repair will just as good as the first box was. You can’t just fill the voids up with cabosil/q-cell it’ll just get too hot and possibly crack unless you set it off super slow. I make the insert by turning a box upside down on top of a piece of foam minimum 1" thick ,then use the box as a pattern. After you make your pencil line around the box you can cut your piece of foam insert down to just at the pencil line (slightly oversized) so it presses in. Sand any raised portion flat. This way when you re-rout it your insert isn’t flying around due to the router bit. Mark 1/2" in from each end right at dead center of the hole, and line up your jig with the center line on the target. After routing remove your insert with your 2 index fingers carefully so you don’t tear it apart, then coat the hole thoroughly with lam resin, insert your insert, coat that, then install the box. Sounds complicated, but with the help of some suncure powder and few drops of catalyst for under the box, I can do them fairly fast, once I actually get to them. Cheers

sounds like a 12 pack job to me, but you might be able to handle it in 6…

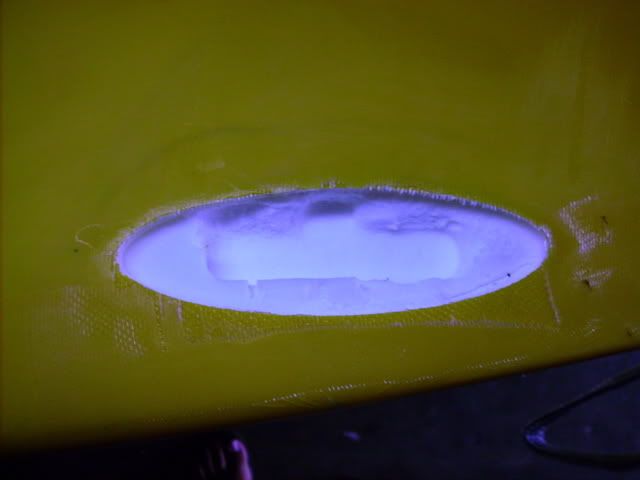

IM DOOOONE! check her out fellas

fish i shaped and glassed in the backround

new fins too

Clean lookin’ job ibsurfer! Please lemme know how she holds up. Cheers Jim