Hi there, working on my next project and got a machine to do my Aku design. I see the board comes with grooves out of the machine and wonder if anyone has used this to the advantage of the design. This is for example not to sand them out on the nose to increase stiffness and reduce vibration - or shape them to the tail on a V shape to cotrol flex only on the tail while keeping the front rocker more rigid. Thanks, WP

I do not understand how it would increase stiffness.

It will only increase air bubbles.

The same as when you fold a piece of paper and you create an edge. Do channels on surfboards create bubbles. Thanks for the comment though

I think the “bubbles” comment was in regards to the laminating.

Lamomating channels should not be that dissimilar.

that is not the same principle mechanically.

It won’t increase the board’s stiffness. A surfboard is a sandwich structure (http://en.wikipedia.org/wiki/Sandwich_theory) and a paper isn’t.

Laminator and sander will NOT be your friends!

True, but the board will be grooooovy!

I thought the term"Groove Smoothin’" meant removing the grooves.

Indeed they do - there is an art to well-laminated channels, and you’ll need to see a machined shape to find out why it’s going to be incredibly difficult to laminate.

Channels however are used as a stiffening device in some designs - such as the rail grooves by Cole Simler. I’ve also seen clinker-style channels shaped in the DECK side for the same reason.

JD

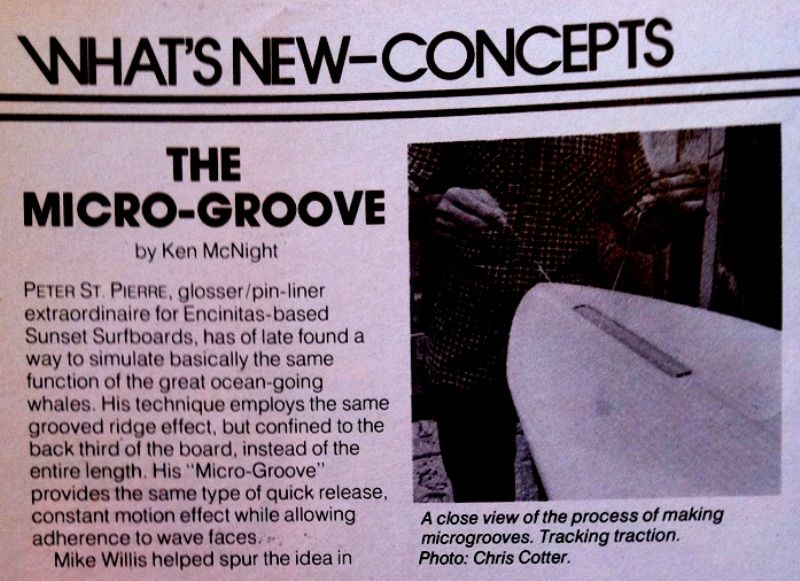

peter ‘pinliner’ st.pierre [nowadays he and son J.P are the ‘moonlight glassing’ guys …]

" micro grooves " …

( …"google " can be your friend ! … )

Get a blank off the machine and glass it. Take for a spin at your local beach break and let us know if there are any revolutionary results.

Things only become possible by trying first. And to those willing to make the effort. I will laminate, sand and patent - but you will be the first one to know.

Things only become possible by trying first. And thanks to those willing to make the effort. I will laminate, sand and patent - but you will be the first one to know. Fins will get it for free - thanks for the pics and micro groove text.

How about making 3 of the same board? One as a control with no ribs, one with some strategically placed ribs, one with ribs to spare (aka the Sparerib, 'taters and 'slaw optional…). Use the same blank material, approximate foam volume, lam schedule, fins, etc… Now you have a test ride quiver and can validate how the design ideas are working in different conditions.

Best wishes on the new design.

Yo, Peckerwood! You’re fixin’ to plow a field, that is fallow. If, and I say IF, micro grooves REALLY worked that well, would you not expect that in the following 40 plus years you’d see it as a near standard feature of surfboard design? Think about it. It’s not out there for a reason, and it’s not for lack of exploration. But, soldier on, if you must.

You should try it. It will add valueble information to what can and can’t work. This is all new because shaping machines are fairly new, and I doubt anyone has tried glassing an “unfinished” board. You may end up with something that works well.

I think you should sand the deck smooth, and maybe the rails and where the fins will go. Glassing will be a chore, but I think you could do it with UV resin and take your time to get the glass down into all those grooves.

Ever since I saw this M-ship, I’ve wanted to make a board with channels that start at the front and terminate before the tail. Not this drastic, but similar idea. I know a guy doing something similar with concaves, and guys that have ridden them say they are really good.

Actually, this has been done before.

I see poorly sanded machine shapes all the time.

Little more elbow grease boys.

Im sure they show after board is finished.

maybe not is Hot-coat was thick.

Seeing how almost all machine cuts are eliptical.

I see no usefulness.

Channel bottoms are a different subject.

ummm…How on earth do you plan to glass a surfboard straight off of the machine? Nightmare city!

I take it you have never glassed a surfboard and you have never seen a machine shaped blank…my oh my…