Hot topic at the Winter Olympics is the new suits worn by USA speed skaters. Something about using Lockheed Martin dynamicsists to optimize surfaces.

Who’s going to do this kind of stuff in the surf industry??

Oh, I forgot.

We do.

Hot topic at the Winter Olympics is the new suits worn by USA speed skaters. Something about using Lockheed Martin dynamicsists to optimize surfaces.

Who’s going to do this kind of stuff in the surf industry??

Oh, I forgot.

We do.

You forgot the hotcoat ![]()

One of the lightest boards I’d ever felt was an old Hana Crew epoxy board that didn’t have a hotcoat. It looked really similar to what you guys are doing now. I was surprised it hadn’t soaked water but the guy had been riding for a year at that point with no water intrusion. He didn’t use wax on the deck either because it was grippy enough without it.

The Lockheed building is in Cape Canaveral across from United Space Alliance, some good tech to be had outta there too ![]()

cheers huie

For anyone else who wants to try boundary flow

This finish has no positive effect on planing surfaces, since the boudary layer seperates at the end of the board. So it is impossible to postpone the separation further by forcing a turbulent boundary layer.

Theoretically the dimples will only increase drag on a surfboard.

But I these dimples can have other good effects, like increased sales due to good marketing.

I have been riding this new tech for 1 1/2 years now and I do believe it does give a little speed advantage.Don’t knock it till you try it.

Anybody remember the boards from about 1985 that had dimple bottoms?

I was thinking the textured peel ply.

Those were more like divits than dimples.Willis brothers made those I belive.

The boards lawless is talking about we’re about 12-15 years ago. Surface was a little different but the lack of excess resin in finish coats was similar.

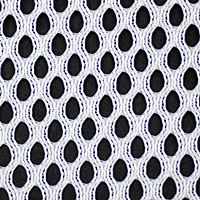

As I posted when we introduced Kick, when we eliminated the “hot coat” and sanding we knew we’d again have a surface unlike conventional surfboards. And we wanted to maintain certain physicals in the lam structure. So Kirk set out to optimize that surface and meet the other criteria. It’s a simpler process and the result is the highest strength/weight ratio anywhere.

Tripping the boundary layer and tripping conventional thinking at the same time. Surfboards move through water in too many ways to be viewed purely as planing surfaces.

Yes I agree. I was hoping that you were thinking further than just comparing with lockheed martin and the olympic skaters. But offcourse you do ![]()

Your boards look very good, and the surface definately gives them something special.

Yes. They were done by the Willis brothers and the dimples were comparitively large. A few inches across, as I recall.

Atomic skis has been doing a dimpled top sheet on their race skis for years. In Ski racing 1 hundredths of a second can mean a win ora loss. Marine Architects are looking at surface patterns to make large hulls more efficient. saving millions in fuel and adding speed.

There by allowing those boards from China to get here faster. ![]()

Im not sure about the highest strength to weight ratio. The 3d of the open voids helps in strength to weight, but that mesh is a pretty open weave, and not the strongest fiber. Since fiber is stronger than the glue, a tighter weave, and stonger fiber would get you there.

Didn’t we have this discussion last month?

http://www.swaylocks.com/forums/rough-might-be-goodsee-i-tol-ya-so

I would say that Coil’s lamination is the strongest in the surfboard industry, even if I couldn’t feel the difference between the kick and normal lam. But I’ve never owned a kick lam’d board and I can’t feel much, either (unless I ditch the middle fin/anchor).

Yes.

The mule is beyond rigor mortis …

My brother and I started using this woven bamboo material about 5 years ago. I have several boards with this without having the weave filled in completely. This is a very strong build and quite light. I don’t think the top or bottom will get punctures like most other skins do. The woven bamboo is very hard compared to any cloth, then we add a layer of cloth over it to finish the lam. This allowed us to use very light EPS for the cores. The weave has a fixed pattern, so the texture is fairly symmetrical. It costs about $35 for a 4’ X 8’ sheet here.

I think this would beat the coils for durability.

lockheed martin? pffft. Give me a break. Until you post your coefficient of friction vs. relative angular impact of water flow across your elliptical surface, you will have to buy my beers at the next meeting.

Pompano, I know you can read. I said that the US Olympic team was helped by Lockheed Martin, not us.

Funny I talked to Michael and Milton today in Oceanside. Michael gave me a bear hug and they are both still physically strong. What amazed me mostly, was their physical appearance both with a ton of hair and dreads. I love those guys and they are stepping to their own beat.