…to be continued !! …

…to be continued !! …

Nice work as usual ben, keeping busy i see!.

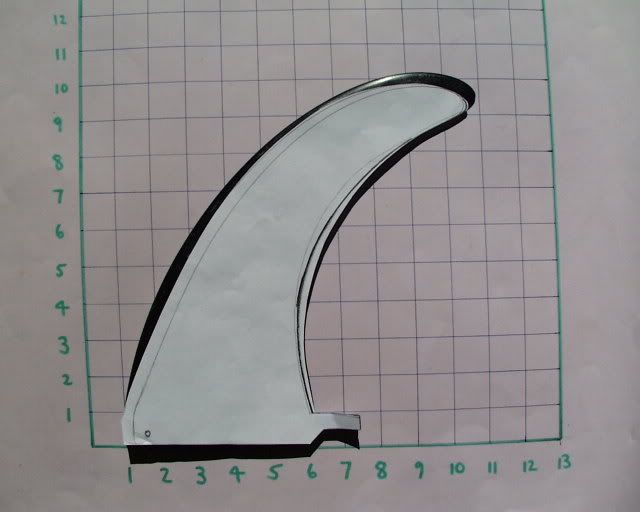

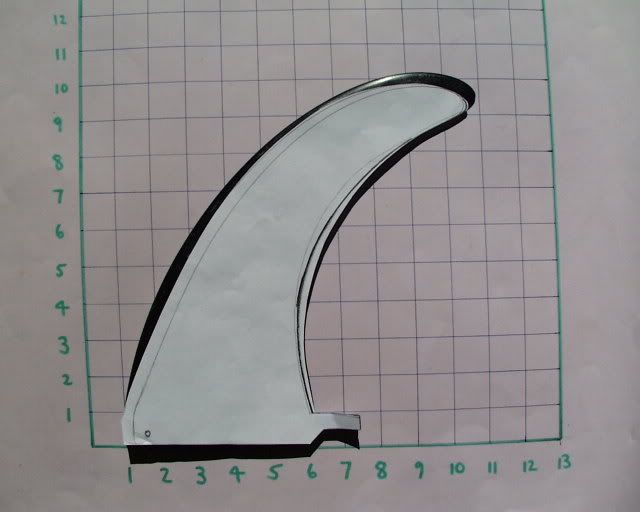

WHat do you think about this fin?? I find it too stiff in both my diamond tail, and my new egg. WOuld cutting it out like i have shown loosen it up???

I was just going to trace 1/2’’ off the outline of the fin, and then refoil it. I may even thin out the top 1/3 of the fin, so its a bit more loose.

Any ideas??

hiya Mark !

how did you go with that fin modification , i’d like to hear / see? how it went ?

okay …

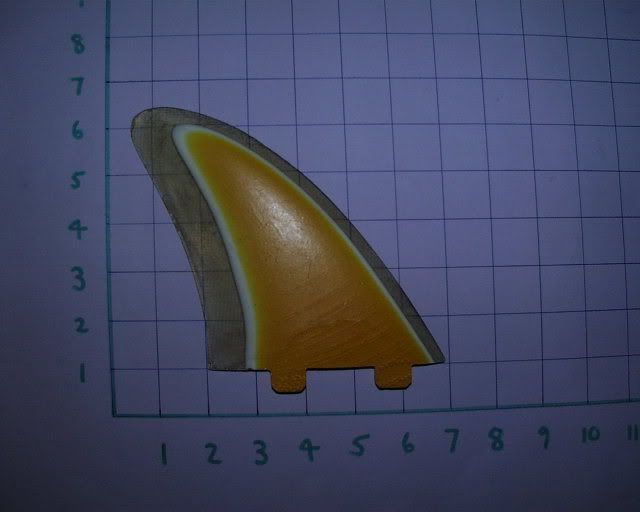

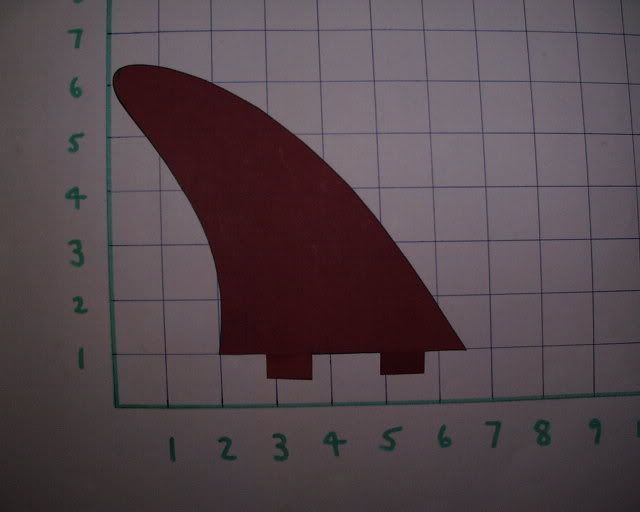

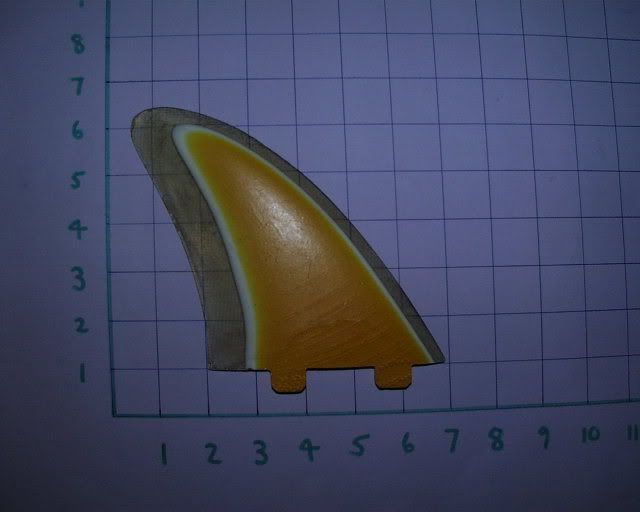

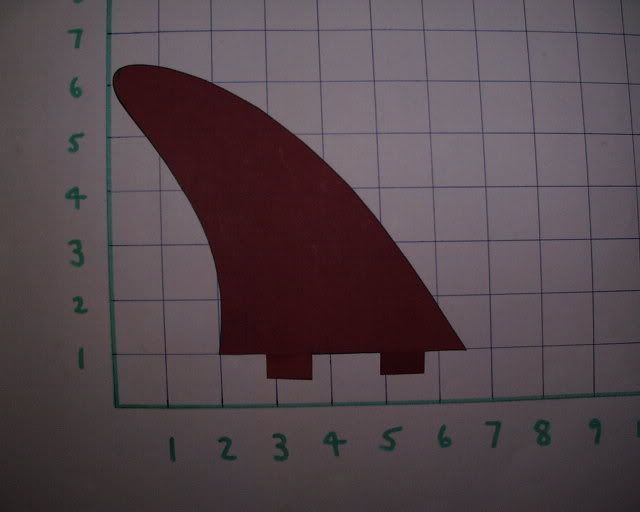

… here are some recent projects…[kevlar one , on the bottom right …]

i have also resized the red len dibben twinnys

…to be continued …

My “Fred Flintstone” trailer fin with “tail” was the best thing I ever did. By cutting off the last third of a normal fin, it effectively moved the in fin forward a bit. I have no skills and no tools other than a hacksaw but this little fin electrified my board.

hi Chip,what do you normally use to cut out your fin panels? i ask because i normally struggle with a jig saw or coping saw but i just bought some grit coated jig saw blades and it just goes through the fibre glass layup with ease, pete

The fastest way to completely change your boards performance.

G10 is the go for fin tweaking.

Chipper,

Taking some pictures and sending you some stuff and information this weekend via Clipper Ship.

Lavarat,

I think I asked you this last weekend after a couple of beers, but forgot. Where do you buy the G-10 stuff? Mike

heyo Chipfins61,

you mentioned the Kevlar fins…

Kevlar is a real bitch!

How are you going to foil/sand them down?

Hey Mike! I was inspired by Ian’s fins and the G10 also, just got some from this company:

http://www.redarrowhobbies.com/fin.htm

1/16"x 1’x2’ just under $40. I have futures boxes so got the 1/16" to give the fins a bit’o’cant then add the balsa for thickness and looks. The company’s fast, I ordered Tuesday and got it yesterday.

Les

Thanks, Les. Mike

Hi mike,

Hope you got some of that swell today it was 12"@20 and dead glass at OB.

I got lucky and got out in 10 minutes.

The g10 sheet I got is from Industrial Plastic Supply 12"x24"x.250 for $44.5

Just get a grit blade for the jig saw,paper painters suit and go to town. The g10 has so many layers of glass that is easy to get a nice smooth foil. With the G10

you can go very thin and still have instant twang.

Have fun,

Ben, it works MUCH better, much more manouverable, more “twang”. Love it now, especially this setup. Keen to try that setup on my shorter single fin, but it doesnt get wet much lately, im getting into the egg in the pic. I have a spitfire in it at the moment, but i havent got it into many waves yet, the twin keel seduced me the other day and i got rewarded with the nicest waves we’ve had in a while, had a ball.

heyo Chipfins61,

you mentioned the Kevlar fins…

Kevlar is a real bitch!

How are you going to foil/sand them down?

hiya lee !

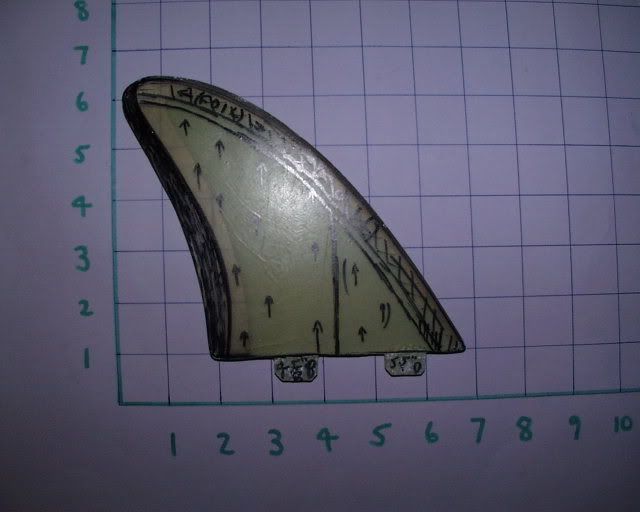

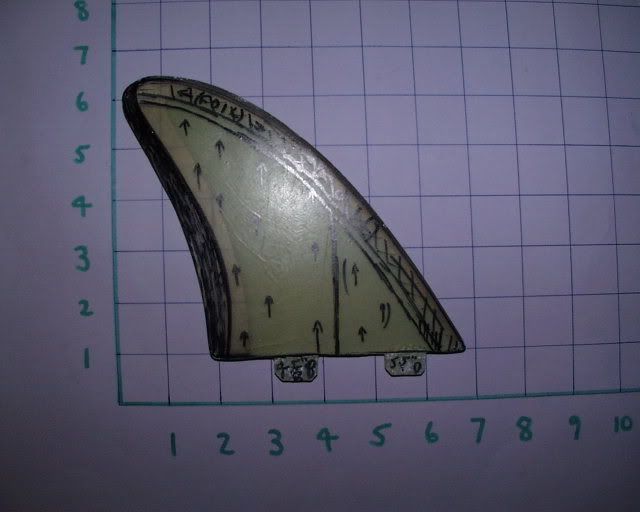

i inlayed only one layer of kevlar in a 40 layer of 6oz panel , so cutting it out was fine [with the carborundum blade in the jigsaw]

entity said kevlar was a mongrel to lap the rails with [he did a kevlar board]

my mate noddy puts strands of kevlar either side if the stringer [and sometimes routs it into deck rails , too…

anyway…

here are some shots of laying up the kevlar inlay panel in question …

enjoy …

cheers !

ben

…still to be further cut out , and foiled [there are two little one-tabbers of kevlar too, for a twinzer setup] …