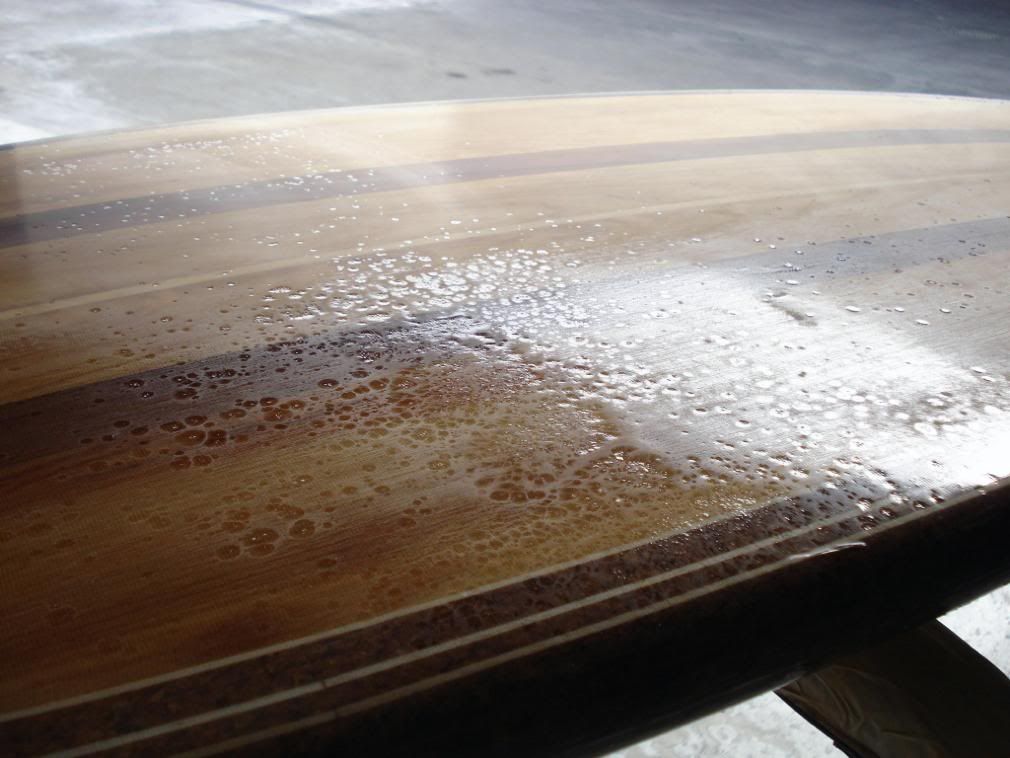

Hey Shifty

I had the exact same thing happen to me.

I haven’t quite fixed that board yet, but you will need to gum up a few sanding discs and sand it almost right back to the cloth and start again.

I have since constructed another board with exellent result.

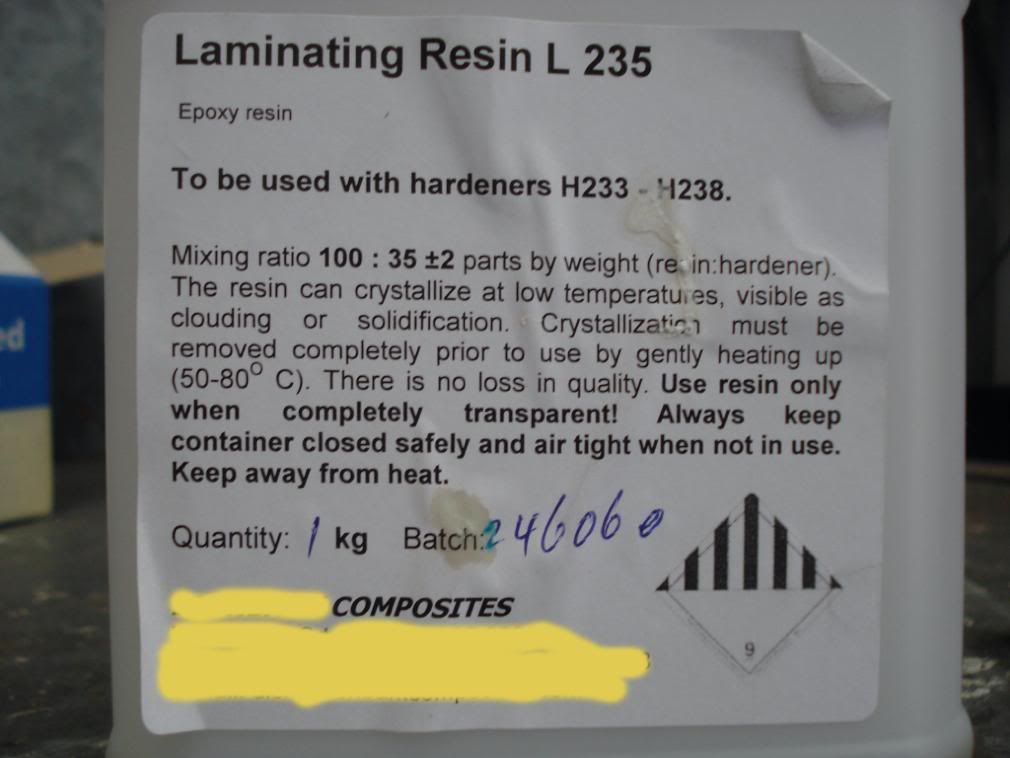

I rang the guy from the resin company (ATL Composite) and this is what he said about the resin.

After your lam has cured, scuff with a scoth pad with water and rinse thoroughly to remove any blush or contaminants.

Give your lam job a quick sand with 80 or 100 grit.

IMPORTANT: Make sure you scotch scrub BEFORE you sand.

I made that mistake. Resin guy told me if you sand first, you sand any contaminants into the resin and makes it harder to remove before fill coat and will result in what you have now.

Make sure your temp is right. (I put a little blower heater on and get it to about 27 degrees C. then turn it off before I coat so it doesn’t blow dust around.

I give my boards a good clean with “wax and grease remover.” Gets rid of any contaminants.

Sounds like you are in the auto panel business so you will know what i’m talking about.

ALWAYs use new mixing pots and sticks. I get mine from woolies. (chinese take-away containers. 5 for about $3.50)

ALWAYS use new brushes. I get them from bunnings for $1.99 each then toss after one use.

Make sure your mix ratio’s are correct and mixed thoroughly.

Fill coat as normal but get it spread evenly then LEAVE it alone to cure.

If you keep trying to fix little imperfections, you end up making it worse.

That should keep you out of trouble for next time.

As for your situation now, you have already sanded so give it a good sand, give it a GOOD clean with the wax and grease remover then re-fill coat.

One thing I have learned about epoxy is that you CAN’T take short cuts.

Good luck

Cheers