This board won’t count as a summer build (1) because it’s winter down under and freezing (2) it’s largely machine cut and (3) It took about 2 years from start of mess to get into the water.

Anyway, a little photo essay of a litany of errors…

When I first build my shaping machine I used to cut from blocks of EPS. But then I got tired of two boards worth of foam dust for each board so I put in some supports and stated cutting from blanks. The mess below was the result of a slight miscalculation. You can see I waited quite some time before deciding the a 2mm tail thickness was not in fact correct:

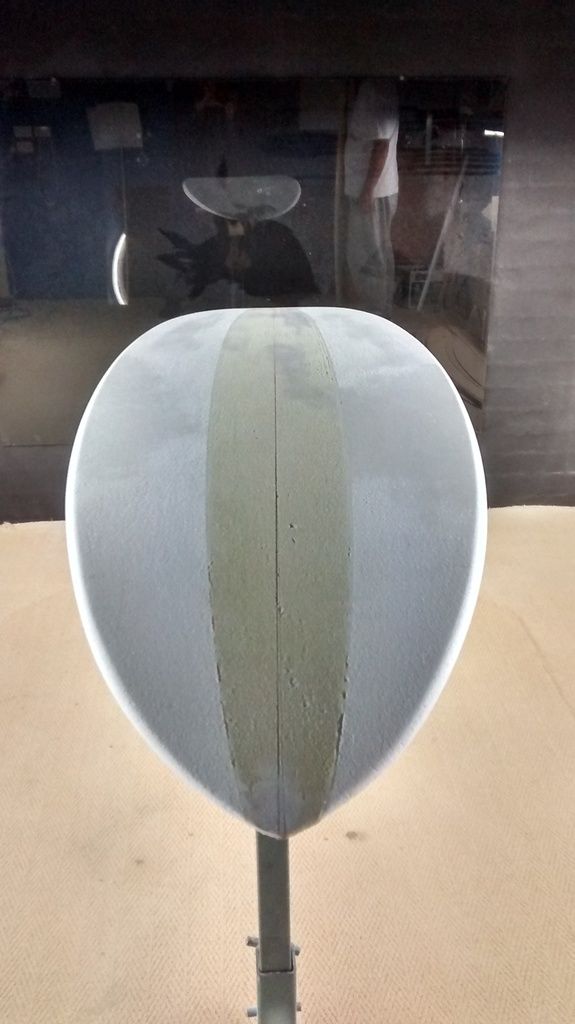

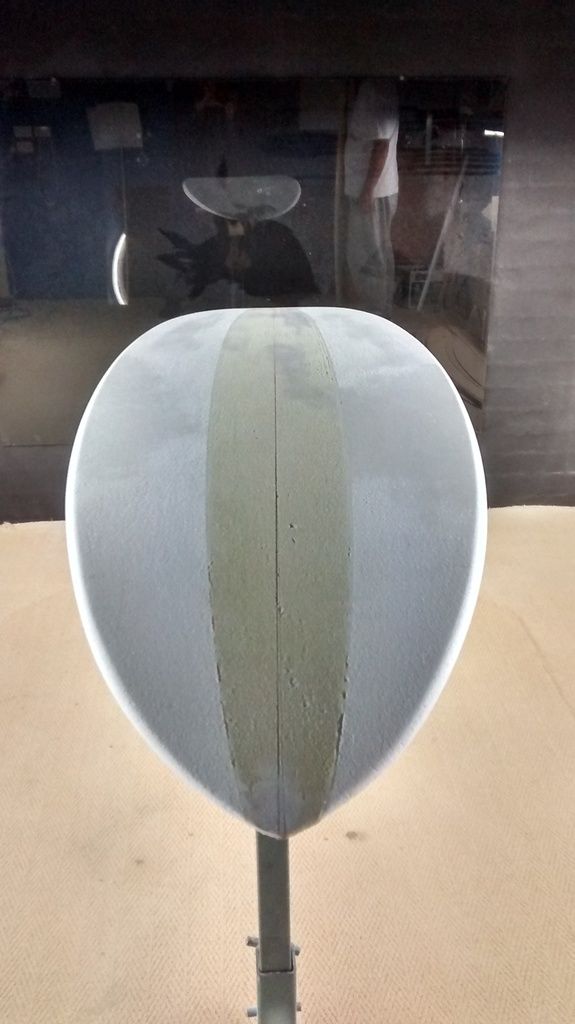

So I had a largely shaped board missing a piece. Of course I made a piece to fit. And being not of sound mind I did the insert out of turd coloured XPS.

You’ll notice the insert needed to be assymmetric. I traced a paper template and transferred the outline to an xps sheet I had lying around and glued it in place using a wood glue-like stuff that ended up rubbery when hard (and that was another issue - you can see in the pic below where I had to pull/cut the excess glue from the join.)

I put is back on the machine and recut the bottom and outline, but the nose and tail still ended up a mess.

I took it down to Stump’s shop and he guided me through taking a couple of inches off the nose and tail using ply templates I cut on my machine, turning the rails and filling the multitude of holes at the EPS/XPS join. Eventually something not too crooked emerged…

A fair bit of filling and dicking around I glassed it under Stumps patient tutelage and ended up with a tidy although ugly board.

No shots of final steps - fin boxes, etc. but I eventually took the beast home and my wife gave it a once over. That’s her signature in the circle.

Gave it a coat of clear acrylic, pulled the tape off the boxes, finned it up, cut pads on my machine, glued them on, and went surfing.

Turns out losing 1/4" of tail rocker and 1/2" of nose rocker has not affected life.

Jury is still out on the half thickness stringer/XPS configuration. Truth be told, in a 5’10" I can’t detect any difference in flex (but them I have been riding an EPS/aerolite composie that has a fait bit of flex).