Once a pigmented lamination is performed, is there any way of adding color after that? Like could paint be applied to the lam coat before the hot coat? Like a dip or something?

-Alex

Once a pigmented lamination is performed, is there any way of adding color after that? Like could paint be applied to the lam coat before the hot coat? Like a dip or something?

-Alex

Zip cut is easy but ya need to reinforce the zip with more cloth. The other way would be a reverse lay up. Doing the deck first then wrapping the clear bottom to the deck which would reinforce the zip in the tail. Sanders would have a better chance of getting a flatter sand if done the standard way bot then top. The reason is grinding a flat bottom is easier then a curved deck. The other thing is you could see a bit of color discoloration where the lap is blended into the color on the deck. You would see that more with colors like tan, brown or any light colored pastels opaque. You will see it more when ya mix white with tints to make opaque colors. Best to mix opaque pigments with white to create pastel colors. Not saying it can’t be done but you’ll have better luck mixing color properly.

Kind of got off track but if ya want to do a lot of color work it’s good to know what colors to mix and the ones not to mix if ya can help it.

The zip cut is easy but to wrap the wide nose is a bit of a trick. The wide round nose lap is. Ya want to cut your lap a little longer so ya can fold such a big flap of cloth.

I wouldn’t suggest painting a lam. It will bleed and you may have bonding issues with your hot coat. Pigment you hot coat. A few people have done swirls with them on the rails and such. And they came out pretty amazing its in the show us your swirl thread Or paint the hotcoat and gloss it.

don’t do paint. I have done it with bad results, but then again, I could have just done something wrong

Thank you for the heads up guys.

A2tall, you said that I could pigment the hoatcoat and then gloss it? Should I pigment and barely sand it, as to avoid streaking and swirls? Then gloss? I have never glossed before, is it pretty intensive?

I’m not sure what your trying to hide but take it from the Oops king. If weight is not a issue then prep the old lam for a 4oz acid splash/swirl over the first one. If weight is then finish as best as you can. Then break out the Posca markers and get funky. Sometimes its better to slap some lip stick on her and go out anyway.

hey xander,

glossing is just basically a hotcoat that is thinned out. nothing really different. you dont even need to polish it if you dont want to. why exactly are you trying to hide your lam?

I havent done the board yet. No mistakes yet Sanolocal! Haha. I ask because I saw a rad colorway done to a board and I cant find the picture. Ill just try to explain it as best I can. So there were two colors: brown and black. The board was definately polished. The top 3/4’s of the board were an opaque brown resin job, top and bottom. towards the tail there were grading black stripes. Sort of like this

Sorry, I did that in a couple minutes. But that was the basic jist of it. I figured he either sprayed the board or he pigmented the lam then somehow painted the stripes on after. But I ruled out the fact of him spraying it because You could not see the stringer.

I also have another question. How did they glass this board? Was the top lam just wrapped all the way around with a huge piece towards the nose?

Thats a reg color lam but zip cut at the tail with a wide nose lap. It could be air spray. Hard to tell but sure looks that way

Is that zip cut hard to do?

ugh, alright so the zip sounds easy enough as long as I go with a dark color. The wide nose lap is the part i dont follow too well. Where would you cut the lap? Would it all lay flat or would it overlap when trying to get it all the way around the nose? Like would it fold on itself? How could you cut it so that the color would stay consistent and the lap wouldnt be very visible?

Alex

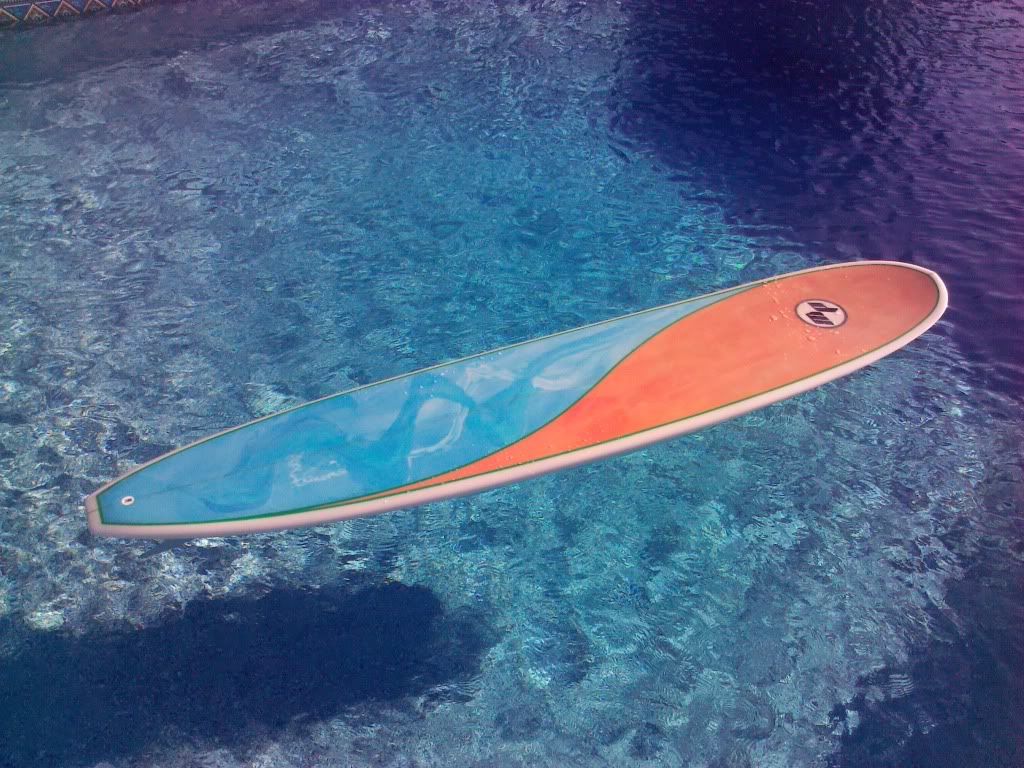

Xander…look at this board. It’s all tinted resin…The bottom is one piece resin swirl cut lap. The colors on the deck are layed up separately with 4oz panels. Just taped off and cut like a cut lap. Pinlines hide the cuts. Then the whole deck has a clear 6oz lam over it all.

This board is essentially done the same way. Clear cutlap bottom, two panels for the deck. I have used cloth as light as 1.5 oz on several boards to achieve color with resin vs paint.There are easier ways to do it. I just like the challenge of doing all my color with resin when possible. It fades way less and I just love the richness of the color.

Also you could do a foam stain to acheive those dark stripes toward the tail of the board you want to build. Then glass it with a lighter “tint” not a “pigment” Just remember “tints” are translucent and “pigments” are solid or “opague”.

Woody, that is very impressive. Thank you much for the info. I didnt know that once you lam’d the top, you could go back and lam it again. That makes thing way more simple. I have one more question though, how would you cut the cloth on that little Tyler Warren in order to achieve that really wide nose job. I know for sure that they used pigment, opaque right?, to color the deck and when they wrapped it around, the made it come way lower the normal.

Thanks Sano for the information as well.

Any pics of the other side? Just guessing but it could be a foam stain (pigmented resin applied like paint under the first lam), could be what sanlocal said and be a reverse cut lap, or just one piece for the color. Then lam over the whole thing with clear. There are guys who do their colored rails this way...looks like a cut lap, top and bottom. When you don't have equal thickness patches meeting each other...you can press the edge into the foam very carefully with a tongue depressor or a wall paper seam roller. I use the wall paper seam roller. If I was asked to re-create that board I would tape it off like a cutlap (I call them panels or patches) I would run it to mid rail, cut it at a tape line...if the top is a similar design or solid I would repeat the process and overlap the midline very slightly. I would acheive a small bump vs. a big bump at the overlap by pressing the edge of the first one into the foam. Remember that these panels are just for visual appearance and have little if any structural benefit and do add some weight. Once I get it to look that way I want then I lam the board as usual. Most any board with a 6oz deck and a 6oz bottom will be plenty strong.