By pour foam I mean the marine urethane stuff. I’m going to cover my hole with a clamped thin bit of wood to give it something to push against. Does anyone know how badly it sticks. Would it be a good idea to put a bit of wax paper on the underside of the wood? The hole is fairly deep, and it’s polystyrene. I don’t want to fill it in the “usual” manner as it would probably generate too much heat as well as use up heaps of my epoxy. Anything else to be wary of as well?

Put the wax paper or a sheet of plastic over the timber as the foam will stick to it pretty good. Keep the pressure on it too or you’ll end up with a mass of honeycomb looking foam.

Regards

Daren

Thanks.

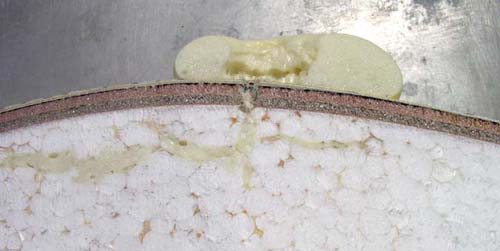

The pour foam here in the US (from US Composites) sticks even to wax paper. Worse, it’s honeycombed with holes that must be filled (lots of filler) before you can glass over it. I don’t know how big of a hole you’re repairing, but for either EPS or poly, I do this: Cut out the hole to a uniform size, shape a piece of poly foam and glue it in with white Gorilla glue (foaming urethane, water activated). You’ll need very little filler if any over this. Pour foam is structural to a certain degree depending on density. The problem is you may not get uniform expansion in a raw hole to fill all the nooks and crannies. It just follows the paths of least resistance and foam out the top (even if taped over). If it isn’t filled completely, you have voids and it isn’t structural at all, just a covered up hole.

I’ve done some sailboard repairs using the sprayed version of the marine PU foam. Clamped down a sheet of ply, the ply needs a release agent, PVA, plastic foil whatever. You also need a couple of holes to allow excess foam to escape, otherwise you get too much pressure and it will ooze out from udner the clamped wood causing major goo gunk on the board. Best to tape off the area around the cavity with some good thick tape first.

Boardlady has some PU fill shots on her website:

I forgot to ask, what density foam are you guys using? Pour foams come in different densities just in case you were unaware.

Use polythene plastic as a release

hey i prefer to just route into the eps and inserta new piece with 5 minepox

and shape it back to the glass

almost invisible

I used if I remember correctly, 8 pound for rails on flex-spoon kb’s. Stuck like crazy to most everything (definitely to wax paper) but no voids or gaps at all and i had to shape it down a fair bit to get those inside curves on deck. I think if you use the higher densities and (8 being semi-high in my book) and mix well and get it poured in time and evenly fill bottom of space it will foam up pretty evenly. At least that was my experience w/ probably 10 or 12 pours.