EDIT: 8/29/06

So tonight we foiled the fins.

Tools Used: 80 grit sandpaper, Grinder, Hand Saw, Spring Loaded Hand Clamps, Vise Grip

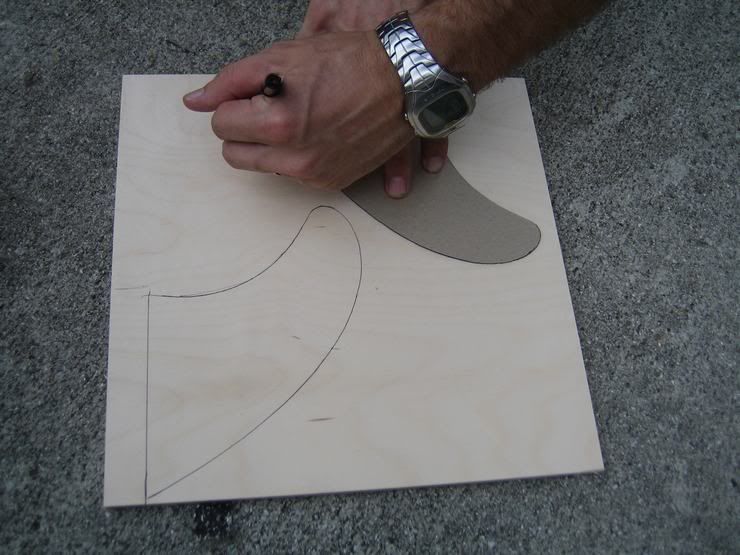

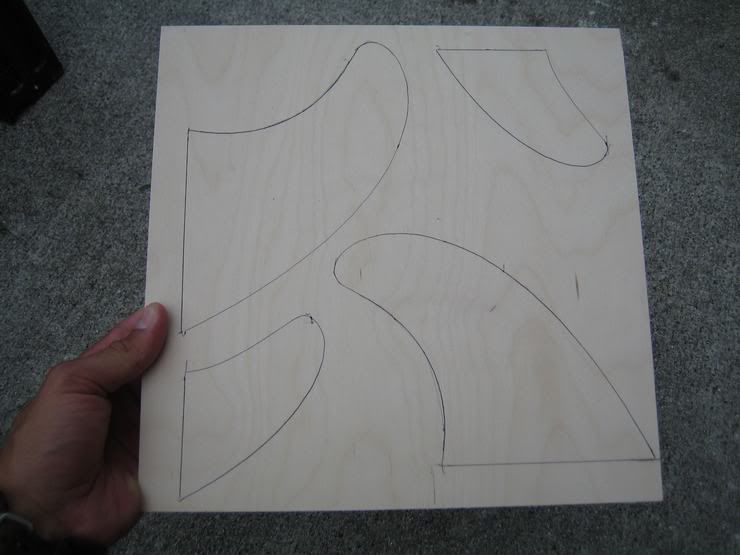

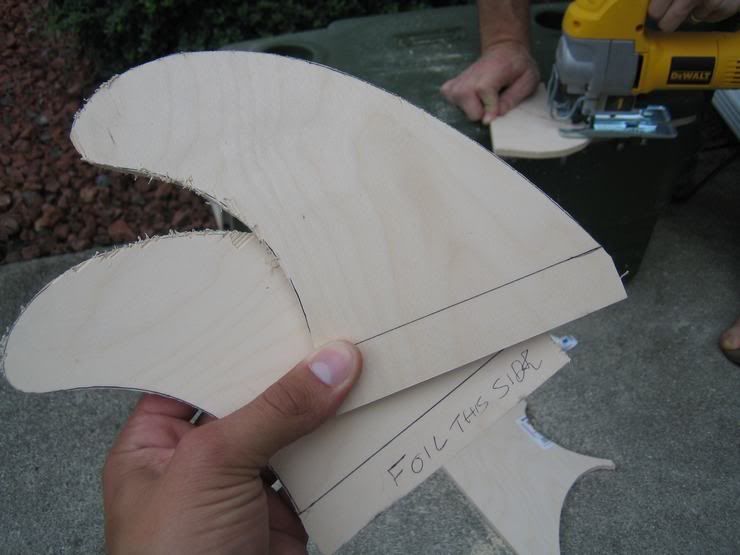

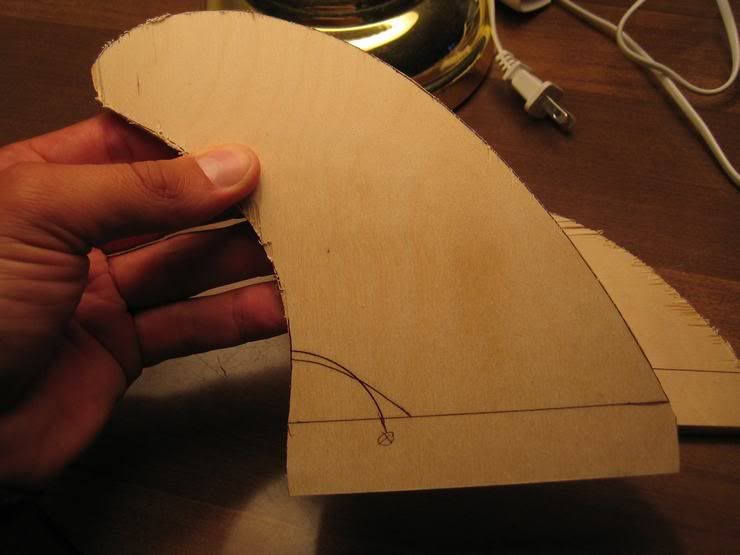

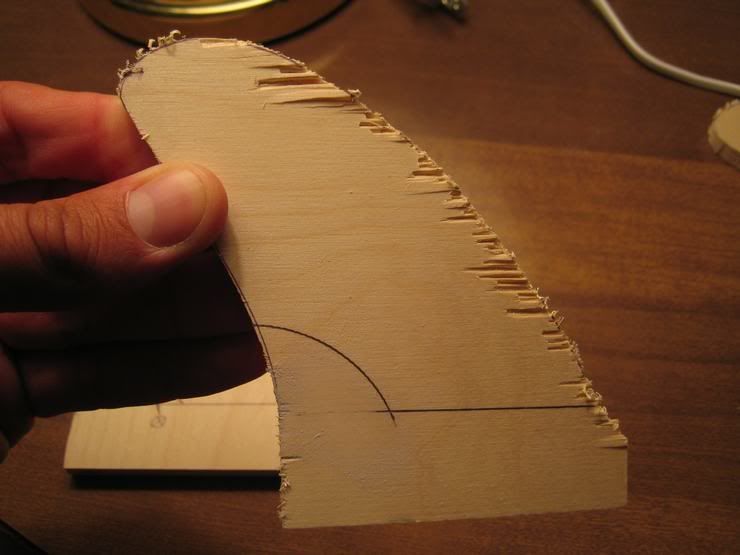

After I cut the shape of the fins, I clamped two like fins together (clamped the two small fins together and two big fins together) using some spring loaded hand clamps, and “trued” up the edges (basically sanded them until even) making sure they were flush and equal all the way around the fin. After each fin matched its twin perfectly, we foiled one fin at a time. Using a vise grip and a hand grinder/sander, we started grinding away at the fin ever so lightly. Hunter has unprecedented skills when it comes to foiling…just look at that craftsmanship!

During this part, you basically want to pull the trigger and let go. As the paper is spinning, you apply the spinning grinder to the fin in short bursts. Never hold down the trigger because the slightest pressure can grind right through it and break it off. Take your time. This is the part that you need to be very detail oriented about. Keep pulling the trigger in small bursts and sanding little scuffs at a time. Since this is all done by “feel”, it may take a few times to get it right.

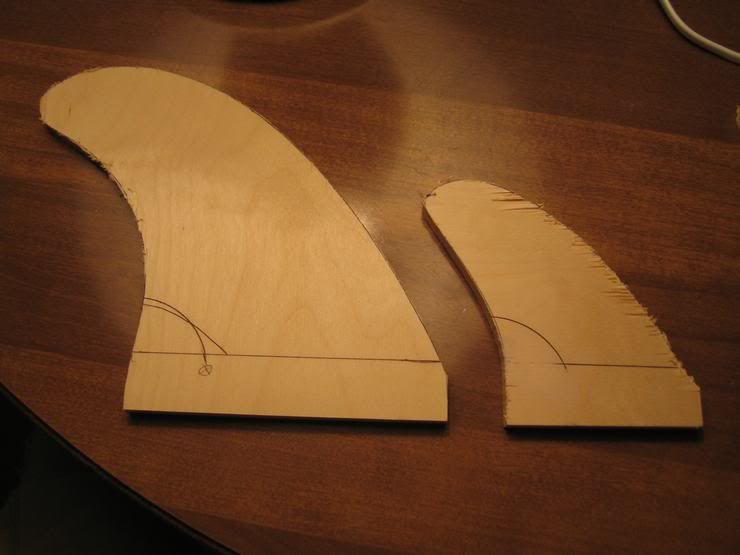

**Please Note: Make sure you foil the correct side of each fin. You want two fins (one big and one small since I have a Twinzer) with the foiled side facing outward to the left of the board and two fins (one big and one small) with the foiled side facing the right of the board. If you screw up, you have to re-cut a fin and true it up again. Just save yourself the time and make sure you do it right the first time!

After the fin is grinded to the desired width/thickness, hand sand the fin from this point forward. That way you won’t break it since it becomes more fragile as it gets thinner. Once the fins are completed, we took a saw and cut off the base. This was also a judgement call. There is no certain area that needs to be cut so you will have to feel your way on this one as well. Hopefully the pictures can help!

Here are the end results. I believe the subtle “cutaway” in the fins looks really cool and hopefully will give it the magic touch. I’ve experimented with everything else…why not the fins! Hopefully we will have them glassed within the week and then glassed to the board.

Since we have a hurricane (well actually a tropical storm that could be a hurricane) heading up this way from Florida, I’m stoked that we might get some good waves! Too bad the board isn’t quite done.

More pics to come so stay tuned!