Awright, lets do this the damn near invisible way.

Carefully, with an x-acto knife* or better yet one of those dental-pick-like tools they have at good hardware stores, pry the crunched in glass away from the foam and just get the bends out of it. Do NOT go nuts with a saw or knife or similar foolishness, think plastic surgeon, not lumberjack. Save as much as you can of that original glass, it’s your friend.

Now, said glass will come pretty close to its original shape. That’s good.

Next step:Fuc# Cabosil-

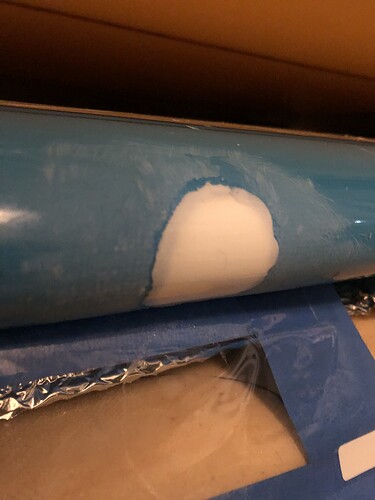

Behind that cloth, squirt a little bit of fresh water, let it drain out, then squirt some White Gorilla glue, Amazon has it**. It expands nicely, but tape your crunched glass over it. Said glue will foam and expand about 3x the original volume. And look just like the original foam.

Or, do it the hard way, don’t tape the crunched glass over it, sand the foam to shape, then stick the glass on it. I warned ya.

Lightly sand. If you weren’t a cut-crazy idiot, at worst you may see a little white in a crack or two, you can live with that.

Next step - glassing.

Make two patches, 4 oz cloth will do, one bigger than the other. Apply using a chip brush and clear sanding resin.

Fuc# pigment, dyes and such aggravation. Nobody ever gets a perfect match, especially when you are putting pigmented glass over original pigmented glass. I sure as fuc# didn’t in over 50 years at it.

On the other hand, your original glass is the perfect color, right? Use it. Clear glass over. Sand lightly, combined hotcoat/gloss, wet sand, polish, call it a day.

Remember, plastic surgeon, not lumberjack.

hope that’s of use

doc…

*Use a new x-acto knife blade. Any rust on an old one will come off in your repair and look like hell.

**Gorilla glue is water-catalysed, the moisture in the air that gets sucked back into the bottle after you squeeze some glue out will make it go off and make it into a paperweight. squeeze all the air out before replacing the cap, you may get a second use out of said bottle.

good luck.