What tool and grit are you using to sand the hot coat?

I do a lot of my sanding in this situation with a sanding block & 60 grit.

Thanks for the thread Huck, nice work all around!

I tend to never throw anything out i think i might someday use. Its a blessing & a curse. Today it was a blessing. I’ve had these chunks of foam laying around the shop (& getting in the way) forever.

Peices a little short but i will improvise on the rest of the indent. Saved the logo, might be able to scan it.

What you are doing for that board, (which I would not attempt) is a tribute to your determination, AND your skill. Bravo !

Thnx Bill no humility just honesty to say more determination than skill at this point, but that’s one reason I jumped into this, I really WANT to improve my repair skills.

The reinforced fill coat is getting in my head. Instead of doing that in an additional step, why not add that extra layer of 6oz during the laminating process. Wouldn’t it still serve the same purpose: to get sanded away but ‘fill’ in any voids, etc?

I’m not against the idea, I’ve done it before, but only when color work or fabric was underneath the lam and I didn’t want to sand into that layer. If it’s clear, why a secondary step?

Also, beautiful work on those boards. What category would they fit under: repair or restoration?

It’s not an additional step, the fill coat, or hot coat, is a basic necessary step that can’t be avoided.

Restoration has a different connotation, so I say remedial work.

Looks good. What did you use to color it?

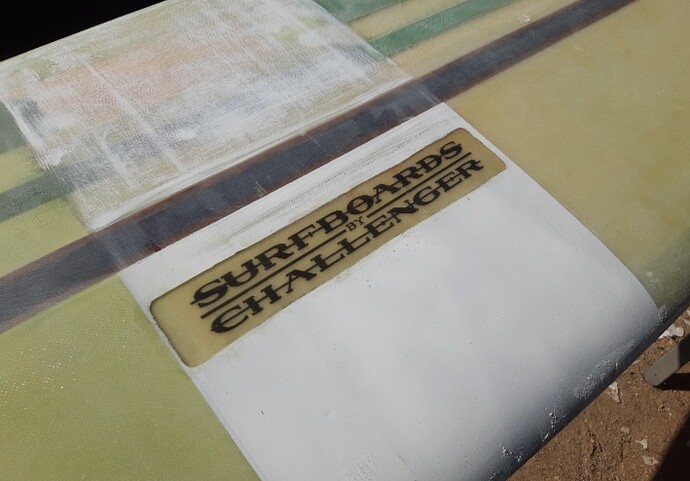

So today, a week after I picked it up, I am just taking a few minutes to reflect on the 10 - 6 pig by Challenger.

I bought the board off Facebook Marketplace, but it was a few hours away, and I wasn’t up to the drive at the time I saw it. The owner (a young woman who’s father was a collector and had owned the board) said it had damage on the bottom, which wasn’t shown in the few poor quality pics.

But she referred me to a surf shop which was handling the sale. I called to discuss the condition. What they said is that it has a channel on the bottom that looks like a car ran over it, about 1/4" deep 6" wide, and 2’ long. Otherwise pristine condition top and bottom.

The sales person assured me he knew what he was talking about, was a collector himself with over 300 boards, knew Randy Rarick, etc etc bla bla bla. Based on his description, I purchased the board over the phone and arranged to pick it up later.

When I picked it up, I immediately noticed a lot of undisclosed defects. First of all the bottom indent was worse than described. There was a big concave on the deck, directly over the big one on the bottom. Both top and bottom had a cupped channel, running the entire length, along both black stripes, but deepest (up to 1/4" in spots) along the wide black stripe (leading me to believe the damage was from heat, being left in very hot sun while the black acted like a heat magnet, melting the foam).

But I also noticed the rest of the board was remarkably clean for a 60 year old board. And they didn’t charge me tax, as I thought they would, because they said it was figured in already. Plus, I figured I bought it as a challenge (no pun intended), and so I figured that hadn’t changed. So I let it slide, and just made the pickup without complaint.

The sales guys in the surfboard department asked me what I intended to do with it, and I told them fix it up and surf it. They laughed, and made it clear they thought I was an idiot, with comments like “yeah I don’t think so”, “where do you surf, do you even know how to surf”, and “be kinda hard with that dent on the bottom”. I just shrugged it off and said yeah I intend to fix it first before I paddle it out.

When I got it home and really looked it over, the board did look un-fixable, and I contemplated just forgetting my refurbishing plans. But I had those foam scraps from the tail of an old blank sitting in the shop, and started thinking about using them. They weren’t long enough to replace all the big dents, but nearly so.

The remaining 12" or so would have to be filled with what we call in woodworking a dutchman, as they were just too big for filler. A band around the board at that area was required, to hide the glue line for the tail foam, to hide the dutchmans, and to visually break the front from the back, as there was no way I could blend the patch so well that you wouldn’t see it.

The channels along the black stripes could be filled with thickened resin and built up fiberglass layers. The fin was original but had been altered.

Considering the extent of the repairs needed, I wasn’t going for a “restoration” as most people use the term. My goal was to take this old board, headed for the landfill, or maybe to hang from somebody’s ceiling, at any rate pretty unlikely to ever hit the water, make it look presentable again, and bring it back to rideable condition.

Not really aiming for 100% authenticity, but keeping as much original foam exposed as I could (not painting over with opaque resin work) and keeping any necessary changes looking pretty true to the era, respecting the historical value of the board.

I have had to remind myself repeatedly not to obsess about certain things, my work will have its flaws, my repairs are not going to be a perfect blend, but just keep my goal in sight, and focus on the improvements I can make, without looking too hard at the many ways I miss my mark as I go.

Jim Philips said, in another thread, that restoration work is a slow and deliberate process, and that a good job is worth doing well. So those words are ringing in my ears. Along with the words and example of master craftsman Gene Cooper, who said I never build a board to be just a wall hanger, I expect every board I make to be ridden.

I like to think that the original shaper, and maker of this board, would be stoked to see it getting fixed up to ride again, despite the fact it’ll look a little different with the band around the tail, and the original stripes a different color (no more black!). I also like to think that someday I may drive by the surf shop where I picked it up, and say “yeah I had a blast on that old board I bought here, now that I got it patched up, I have it with me if you want to check it out”, and blow the smug smartasses away. Maybe that’s just a fantasy, but it helps keep me going on this, haha.

And I’m just grateful at this point to have made it this far without any terminal errors.

Magnificent thread.

Inspirational.

Same thought occurred to me too; 'be even better though if you bumped into them out in the water after they’d just watched you catch the ride of the day on it.

Nice one Huck - will be very interested to see how it turns out once you’ve finished it.

Thumbs up & Cheers all!

Are you painting in a new ‘stringer’ or are you actually using wood? Nice job.