There was a discussion on another thread, where I said EPS doesn’t make a good travel board, because if dinged, it will suck water. Another sways member mentioned that super fused EPS doesn’t suck water like the regular EPS. So since I know that other Sways member is doing some pretty interesting builds, and has my respect, I wondered if I had it wrong. Maybe the superfused is as good as PU foam.

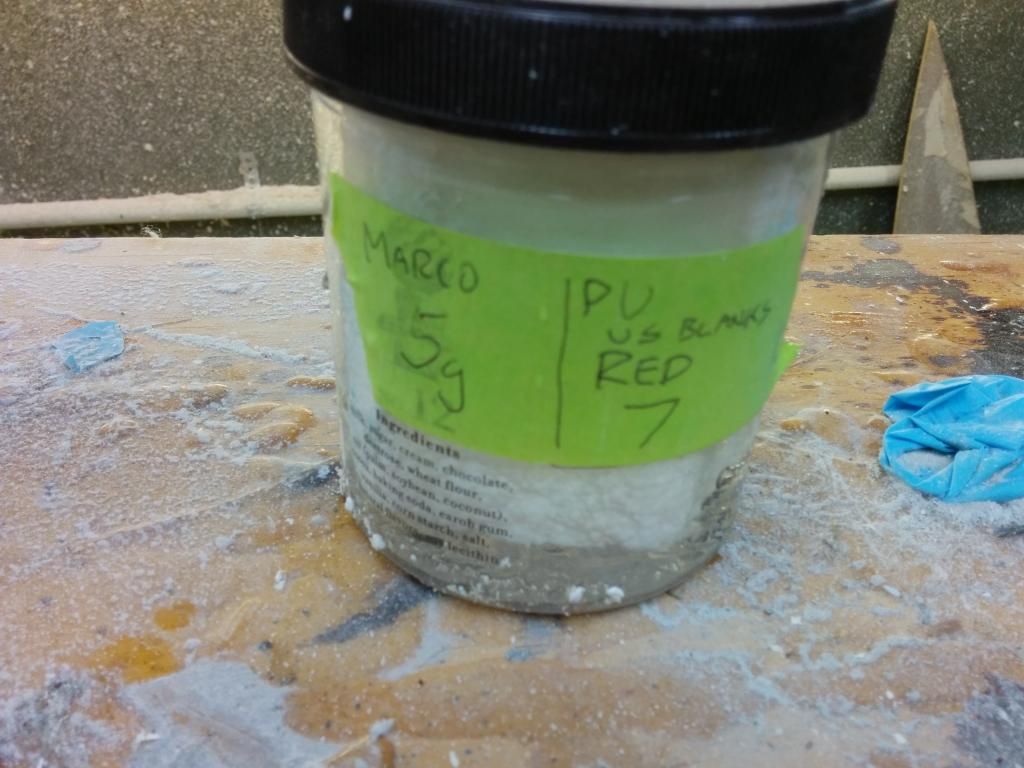

Well, I had a scrap of Marko super fused blank in my shop, as well as some US Blanks Red foam. So I did a little test.

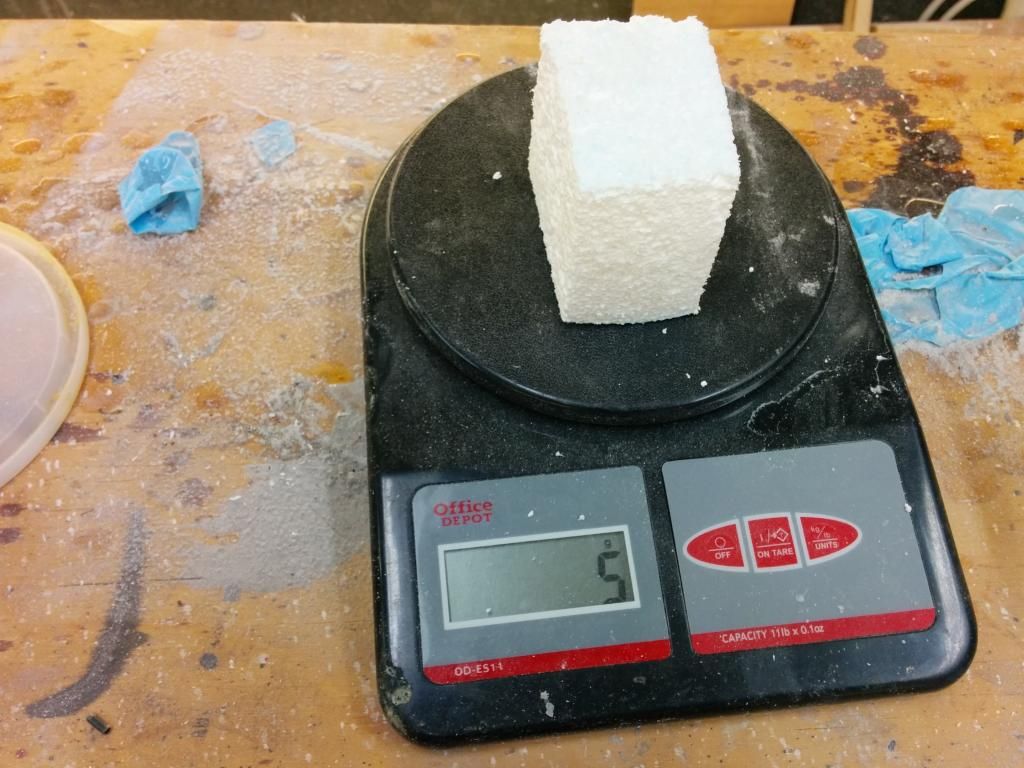

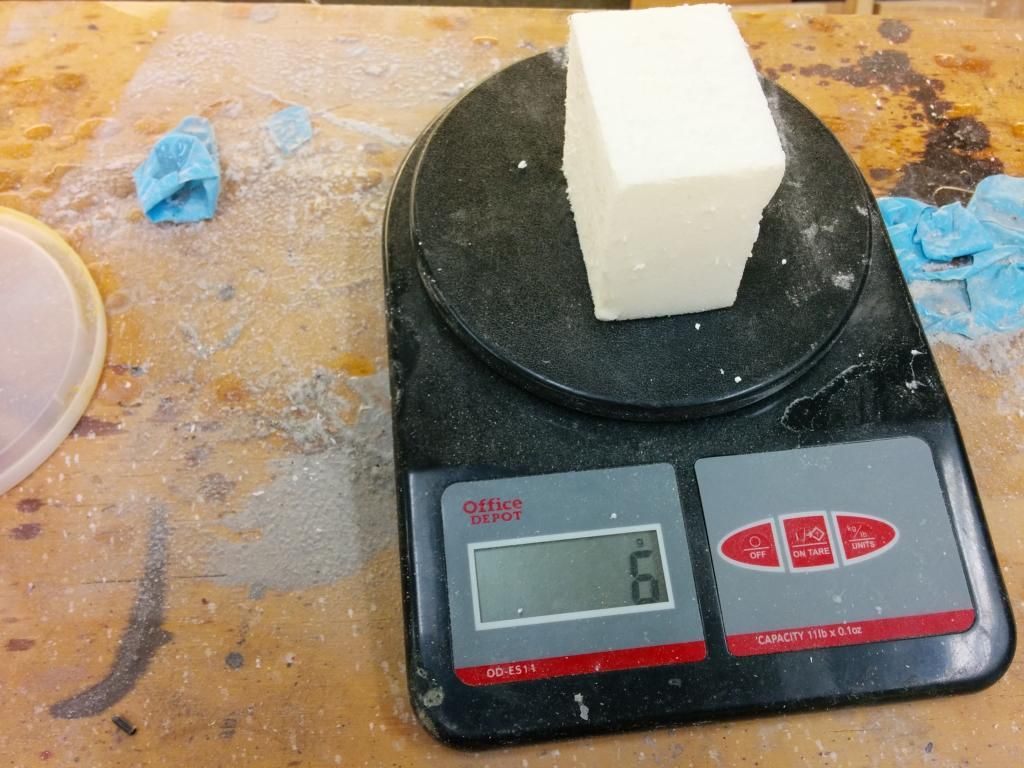

I cut two blocks of foam the same size and shape. Then I weighed them dry.

Dry EPS

Dry PU

The EPS block weighed 5 grams, and the PU block weighed between 6 and 7 grams; the scale kept switching between the two numbers.

I took a jar, filled it with water, and then left teh blocks of foam to soak a couple of hours.

Both soaking.

When taken out, the EPS block weighed 7 grams, and the PU block now weighed 9 grams

Soaked EPS

Soaked PU

So at this point, the EPS isn’t looking so bad. Both foams added about 2 grams of water.

But then I did something interesting. I put them both back in the water, and squeezed them. Just like the board gets squeezed when you stand on it and ride a wave. When the EPS block was squeezed, lots of little bubbles came out. That didn’t happen with the PU block.

Soaked and Squeezed EPS

Soaked and Squeezed PU

So after the real world surfing squeeze test, the EPS block now weighed 13 grams, while the PU block grew to 11 grams.

So what’s this mean? It means that if you ding your EPS board, and stay in the water and surf it, the blank will almost triple in weight, and will draw water through the entire board, as it blows out air when compressed, and sucks water back in when released. It also means that your PU blank will soak in water locally, but not let the water go in as far. It didn’t “breath out” air to suck in the same way. It increased its weight about a half , or 57%

So my conclusion is that for a board that you don’t mind getting out of the water as soon as its dinged, EPS isn’t so bad. But if you are a long way from home, and you want to keep surfing after a few scrapes, go with PU foam.