routing can sometimes be great

now that i have a variable router with dust extraction i started to use it to try and make some fcs related models

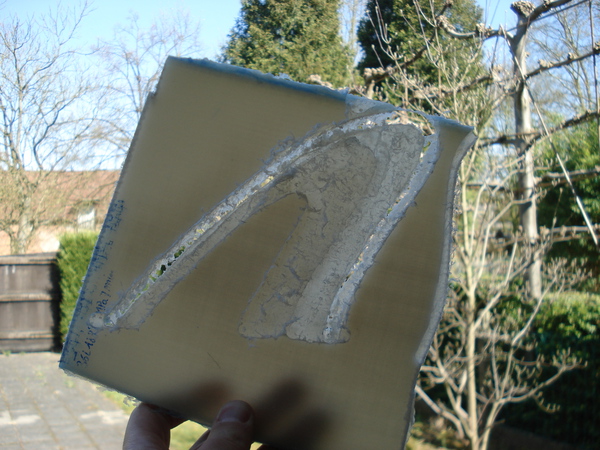

first pic is trying how much or little resin works in xps [that i dont want to laminate anymore]

second is a bit later, when i found you have to add hollow glass balls to add volume - copy router bits need a bit of working area vertically…you want to move the router up and down, to get all the ridges

this here 3rd pic shows the cleaned up work - as you can guess, i used a lot of double sided tape to hold it in place

===============================================================================

4th pictures

an overview of stuff i used

i will make 1 wooden routing template that is thicker, instead of 2 on top, just figuring it all out

==========================================

actually, what i am trying to make next…

is an insert that you can put into the Fusion install template

the insert has the 2 fcs plugs perfectly routed out

that way, you can add your fin markings, draw the fin line

get the router out

route the holes perfectly , no jiggety edges

only nice if you reinforce it all of course, for compsands, or pre-installed reinforcements

but backyarders have time to play with

so what do you all route?

Wouter the router