I’m all for math Dave, I just want to know what it is about the thickness of the rail as a percentage of the thickness at center you find of use - aside from scaling… Then again, you could do that math as you saw fit.

Only new here but Ive never seen a rail volume calculation before so Im impressed. Its just got to be refined a bit. Onya Dave !

cheers for being open to learn other methods guys, actually scaling the board with the 3 programs commonly used keeps the same percentage figure…

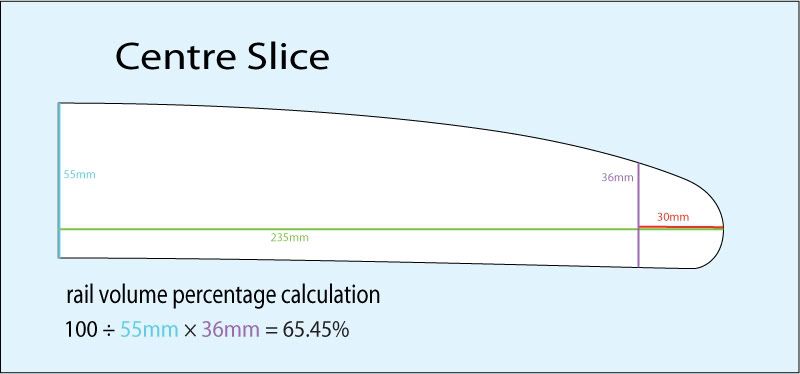

I find it most useful as a teaching aid for educating customers as to the difference between deck shapes and rail volume on different models, also refining custom boards over time with long term customers.

the basic centre measuring setup i have displayed is a good common base. over the last couple years i have gone right into detail with the measurment over different areas of the board but this one in the centre has the most change and the simplest to work with for everyday people… maybe replacing the old pick it up and put it under your arm measurment for me…

here is three different models with the Rail volume shown… you can see the obvious theres a lot more going on than at 30mm in… but it certainly helps understand a bit more about my shape models (and the method of my madness). as we all know theres way more going on to a board rails than this… but this measurement is what i am posting about!

Hey Dave, maybe these guys are right and we should dispense with all this measuring and math, etc. Let's get rid length, width, and thickness; let 'em guess.

These foams, resins, and fibers are all made with math and (gasp!) chemistry, let's get rid of them too. Throw away the computer. No more science!

Hey Dave - great stuff ! - I’ve been doing the same thing but in just past the bottom tuck - so my distance in is 3/4" in. I’ve been using a T square and ruler to measure but I like you’re calipers better. I always have to remember to subtract a 1/16" when I measure a finished board to account for the glass job. Keep it coming - regards.

Okay Mike.

I’ll cut up my rocker sticks for tonight’s fire. My rail contour caliers won’t burn but I guess they will take them in the recycle bin, and all those deck and rail tracings and castings for customers can get shredded. I may as well get rid of 40+ yrs. worth of templates too. I’ll trust what vision I have left…do it ‘by eye’.

I feel better now, lost, but better… really, I promise!?

Now where’s that “Oingo Boingo” song?

Hey Dave

Good idea.

What should my rails @ centre be like for me in height and or percentage?

5ft11 * 20.25* 2.5 thick groveler... whatever that is, but flat bottomed 3-er for knee high to waist high waves.

My weight is 78 kilograms

Cheers

Interesting thread, rail volume is a design factor sometimes overlooked, probably usually overlooked by the board buying public I imagine.

[quote="$1"]

Hey Dave, maybe these guys are right and we should dispense with all this measuring and math, etc. Let's get rid length, width, and thickness; let 'em guess... [/quote]

This comment lost me, 'tho - which "guys" are you referring to?

The guys who think there's no science in surfboards.

Time to get your measuring devices out Wouter…

check all your favourite boards, take notes and get an idea of your optimim rail volume percentage…

lets get everyone to post up thiers and we can start to find a common ground to work with…

darn, i though i could cheat time here

i have tried this before, but there is a problem with this sort of measuring:

if you slide your measuring device on the rail, it want to go a bit sideways, with opening more towards the ceiling.

that is sort of the downside of this way of measuring, it is not very 'fixed'.

but... i will go about it and post results, hopefully tomorrow [too little time in the shaping room]

---

Maybe a circle inside the rail contour with a certain diameter is a better way of measuring!

Because if you make the board thicker, the percentage number gives the appearance of a thinner rail, which is wrong. And rail surfing is what it is all about for HP equipment you talk about, right???

[quote="$1"]

Hey Dave, maybe these guys (who think there's no science in surfboards) are right and we should dispense with all this measuring and math, etc. Let's get rid length, width, and thickness; let 'em guess.

These foams, resins, and fibers are all made with math and (gasp!) chemistry, let's get rid of them too. Throw away the computer. No more science!

[/quote]

Science, meaning bascally a "systematic enterprise that builds and organizes knowledge in the form of testable explanations and predictions", is a tool that can be and has been used in surfboard design.

Surfboard design, however, has eluded complete explanation and prediction based on mathematical equations alone. There are just too many variables to be quantified - and so, a lot of surfboard design has been by theory, conjecture, aesthetics, trial-and-error, etc. A bit of art and bit of science.

Measuring rail volume with a mathematic formula will be of interest to some, less so to others. I realize your comment was made in sarcasm, but I really don't think either viewpoint is "right", just different ways of looking at it.

The most scientifically influenced surfboard design to date, is I suspect, the "fat penguin". In the words of its designer, The deck draws on "Bernoulli’s principles" to create a narrow waist to encourage the fluid flow to hug the body form e.g. Spitster boatail bullet, SR.71 Blackbird, Migs, f16 ...The hard science used to evolve the FP project is the same as NASA and Japanese Aerospace Engineers used in designing the space shuttle and NASP pressure wave gliders. There is also a mathematical formula to describe the flow shape that took over two years to assemble using the theories of Archimedes, Newton, Freude, Reynolds, Chung, Burt, Rutan, and Helmholtz..

Yet very few surfers have embraced the design, or even tried it. Often times this reluctance is based on nothing more than aesthetics. So science sometimes takes a back seat to fashion, but somehow we still manage to paddle out and catch a few fun ones!

LOL. You can’t be serious.

The "Fat Penguin’’ was a hoax.

Don’t clutter Dave’s thread with that bs…

[quote="$1"] LOL. You can't be serious. The "Fat Penguin'' was a hoax. Don't clutter Dave's thread with that bs.... [/quote]

Really - a hoax? BS? Please do clarify - do you have a link to the story?

I don't know much about it, other than what I've encountered here on swaylocks, and surflibrary.org. I think one of the Hawaiian swaylocks bros was making one awhile back IIRC. What about is a "hoax", and how was it exposed?

Here's a link to an Austrailian news story from 2009 on Paul Cole and his unique surfboard design. No mention of a "hoax" - was the hoax exposed sometime after 2009? http://www.theleader.com.au/news/local/news/general/surfs-up-for-fat-penguins/1634944.aspx

I searched internet for "fat penguin surfboard hoax" and wasn't able to find anything. As noted on another thread, there's a two page spread on Paul Cole and his fat penguins on page 100-1 in Smorgasboarder magazine (current issue). No mention there either of fraud, 'tho.

I'll be waiting for the explanation / clarification of your "fraud" allegations, sounds interesting, if its true.

Not so much, 'tho, of course, if its just careless slander without any basis in fact, LOL.

…hello Feraldave and MD; I refer to what possible can occur, as well Wouter say in his last comment

I hate F#$King Computers ha ha ha

Hand Shape

e.g

thickness 2 1/4" x 25.4 = 57.17mm x 0.6 = 34.29mm (this is your rail thickness @ wide point) then bevel the rail at desired angle towards the stringer (I have 3 angles that I use). bevel (off the rail), flat (off the stringer) and then the other bevel between the two is a give me (ease) just blend them all evenly.

This works with all thicknesses.

As long as you can blend a smooth foil off your bottom curve from middle to nose and tail, then bobs your uncle, easy peasy. Thanks for coming!

As long as you can blend a smooth foil off your bottom curve from middle to nose and tail, then bobs your uncle, easy peasy. Thanks for coming!

jeez yorky, you make it so easy,lol, im making one right now and trying to blend the deckline so its smooth from my bottom curve and thats not so bloody easy, lol. I hope you can remember the pain of trying to learn that skill, though its fun to try to get it right.

ok so here is a scenerio…

customer walks in my shop… he picks up board with concave deck like this…

he thinks the board is too thick for him as he thinks its at least 2 1/2 … but its actually 2 1/8 in the centre…

he then picks up a hp shortboard thats 2 1/4 and says this ones about right…

these diagrams are tools help to show him the volume and what different deck rolls do to volume distribution!

im all for educating my customers to help communication and understanding of how we arrive at what works for them…

Gotta get a set of those coordinants about every foot…