Hey – first post, first board. I was hoping to avoid posting completely, but I’m at a point where I’d rather ask and get slapped around a bit than go back to learning the hard way. So, on to my question…

I’ve looked around here a bit, and while I’ve found information on how to trim down the stringer (spoke shave, sharpened-beyond-belief block plane, block plane with angled blade, block plane with custom-cut convex blade, packing tape on both sides to help save the foam from damage, finish sanding to help the block plane slide, etc), I can’t seem to find anything about tolerances. Mainly what I’m looking for is, if the stringer is 1/16th or 1/8th of an inch above the foam, do I still run the risk of the board delaminating, or will the fiberglass and epoxy combo make this difference a non-issue?

Ideally I’d be able to plane the stringer down to perfection with a block plane and call it a day, but I’ve tried this and had to completely reset using an electric planer to remove all the chunks and crappy spots that resulted from my attempt. I’ve got the board back the way I want it as of this afternoon but the stringer is, yet again, just a bit too high. I know my first board(s) will be imperfect in a lot of different ways, but I’m not sure if I can afford for this to be one of them.

Help?

Update:

With all the help and advice that was given in this thread I thought I’d follow up with some details on what I ended up doing.

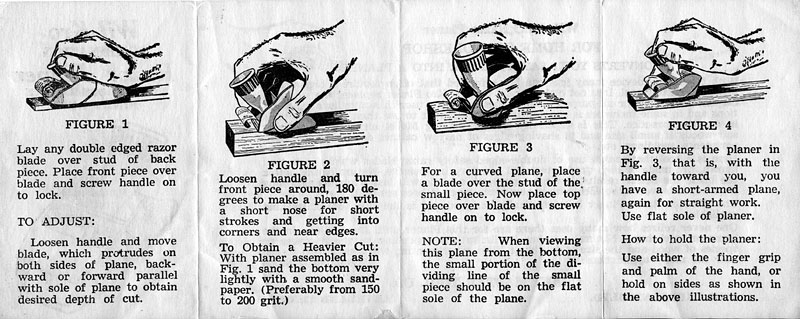

First, I ordered a Wilkro razor plane.

Next, because I’m impatient (it wont be delievered until a few days from now), and because I found what I felt was a workable sharpening solution for me, I put together some sandpaper and honing compound so that I could sharpen my Home Depot block plane.

In case anyone wants more details, the two black pieces of sandpaper are 400 and 800 grit, the greys are 1500 and 2000. The green mush is the honing compound, and of course I had to get a honing guide to help with precision a bit. I used some 3m spray adhesive that I had lying around and a piece of plywood to clamp the sandpaper to marble tile so it would be as flat as possible. It’s not perfect, but it seemed to work ok for this.

I took the blade out of the plane, sharpened it (per some youtube videos and an instructables article), and then tested it out…

The results were better than I expected! With very little pressure, very little exposed blade, and a good angle, I was able to get the plane to cruise fairly gently over the foam, cut curly-q’s out of the stringer, and not cut big chunks or divots out of anything. Success!

My technique still isn’t perfect, and as you can see the foam around the stringer is still a bit on the rough side, but this is leaps and bounds better than what I was able to pull off before! Not to mention I now understand that it is possible to get the stringer lower than the surface of the foam.

SO… big thanks to everyone who commented on this thread and got me pointed in the right direction! I think I may still grab a spoke shave for the nose, and possibly a higher-quality block or japanese plane, but for this first board I think I’m good to go.