Does anyone know a method to figure out what water temps my homemade surf wax is most suitable for?

Hi storm, I felt stucked in that same matter…

I made my waxes with differents percentages of ingredients and test them out in the water… After a great time I finally get to the formula I wanted for both conditions…

But of course, this is not the method the great industries uses. I would be glad to find more about it too…

Glad to hear I’m not the only one in this position Yago. Maybe someone will help us out on here.

- comment deleted as duplicated post *

I think you can label it ust about anything you’d like. I tend to use colder temp wax for whatever water I’m surfing in only because I like it more tacky and don’t mind reapplying it often. But if you want to make some subjective measurements…

Buy some commercially available wax at different temperatures, then play around and compare them to your wax. Surf them, rub them on wood planks, leave them in the sun, wax your friend’s car windows, melt them and measure the melting temperatures. All this testing will probably cost you $20 in thermometers, wax and small aluminum pots. You’ll have a fair idea of where your wax falls as far as usable water temperature ranges.

Good luck, sounds like a fun project.

I think you might be overthinking this and putting way too much faith in surfwax companies.

I like Gunkie’s suggestion

Thanks Gunkie, appreciate all the help I can get right now on this.

I was orignally going to label the wax without temps on the box (think Palmers), then I thought about just taking the average temps of all surf waxes and just putting that on the box (even though i knew i hadnt actually tested what temps it was suitable for) but now its really bugging me not being able to accomplish this properly. The melting point is easy enough to find, but ideally i want to find the temp range of the wax when it turns from brittle to soft and then soft to melting point - problem is, the subjective measurements you talk about, i cannot find any tried and true methods to do what i need.

My original post was very long so i simplified the original question in this thread but in my original question, i mentioned i know of some individuals who know nothing about wax (and ive tested their waxes to verify this) but yet they come up with water temps for it. Its just annoying me i cannot do this final part which is incredibly infuriating as i spent a good few years now researching the best methods to make good wax. I will at least start with the melting points but could really do with some more knowledge from anyone who might be able to help.

My thanks again Gunkie!

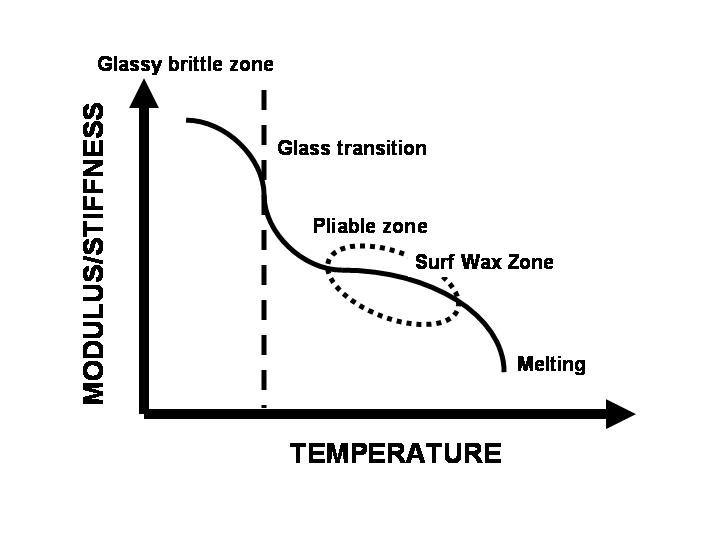

PS. Here is an image which shows graphically what I want to find out:

Chris, you may very well be right. I do over think stuff a lot! I guess I was taking the surf wax companies at their word that they might have actually tested their waxes to come up with the temps. Perhaps it is just BS on their part and they don’t really test that much. So confused right now.

I would say a pot of water on the stove top with a thermometer should tell you what temps are best for each wax. Then check local water temps for each season.

Thanks Huck, and everyone else who has commented on this thread so far. I appreciate the advice more than you all know ![]()

I am hoping to perhaps find a more scientific method however, so shall keep my fingers crossed someone on Sways might have some experience in working with waxes on a scientific level.

I’m with Chrisp on this one. You are probably overthinking it. My guess is wax companies derive their temp ratings the same way shapers refine shapes: trial and error in the water. Softer: colder water; Harder; warmer water. Make a batch, go test it. If it works well in that water temp, that’s the range it should fall into. Give it a 10-15F range so you can sell multiple hardnesses and make more money. Frustrating if you are a data-driven guy, but I bet that’s how it’s done.

Jamie, have been thinking about what you said today and what everyone else’s opinion has been and I have decided that I defintely over thought this one. In my head, the surf wax companies had some specialist equipment or some magical machine which told them the exact water temps. On reflection today though and after having looked up all of my competitors waxes (who use a similar formula), it has become apparent that most of their waxes are falling into the same temp ranges. With that being the case, I am going to mark up the boxes with the same ranges (after having tested them in the water within those temps) and leave it at that. I could probably find equipment to do what I want but it would no doubt cost thousands and the readings I get back would at most be only one or two degrees out so its simply not worth it. Thanks again to all of you in this thread who have helped clear my head on this particular “problem”. It drove me mad for 6 weeks at least! lol. Anyway, as a thak you to all of you who helped me reach this conclusion, I would really like to send you all some free wax. I don;t expect anything in return at all, its just a thank you. If any of you are up for that, if you send me a message with your details and what water temps youre after, I will get those out over the next few weeks. Massive thanks again everyone and proof once again that Sways is always the place for friendly helpful advice. Thanks again boys ![]()

Hi my friend… I agree that you might be overthinking this… But I do that all the time either… It’s the best way to improve what your doing I guess…

Here I got some tips from my last experience: (First of all, sorry in advance for my english mistakes (I’m a litlle bit in a hurry but want to reply you on this)…)

I think a good way to go is to pick up some trusted wax (one that you want to make yours looks like) and make some experiments…

Put the “good” wax and your wax into the same recipient with controled temperature water, and watch how they work (after a few minutes, try to wax your board with each one of them and take your notes)

Another good way to go (for me) is to wax your surfboard with your homemade wax and another (“good”) wax… And then go surfing… You will see how they work in the same conditions… You can feel the difference (one probably would be more sticky than the other, or probably would be harder to get off the board, etc…)

And after you make this pratical experiments, you can go back to your surf wax formula and try to change the amount of each ingredients to get closer to what you want (First of all, I would recommend you to study the effect of each ingridient, so you can manage to get them all together to reach your goal)

Hope this helps a litlle…

Good waves with your wax!!

Thanks Yago. As I have said, I completely appreciate yours and everyones efforts with the help/guidance I needed on this particular matter. One of my main problems was that I wanted to lab test everything before I tested in the water in order to save time. I am pretty happy or more than happy with my formulas so far, so testing in the water is the next step to gauge their suitability within the temp ranges. I will update this post when I have tried them under the different temps just so people can see how it turned out. Hopefully this thread helped you too as I know you were kind of in the same boat deciphering how the wax companies graded their waxes for certain temps. Thanks again and will get wax sent out if it interests anyone who has helped me out. Working on your own on projects like this is great but you can be your own worst enemy over analysing things I guess! ![]()

Hi Storm-

I wondered where you went to after the molding thread…glad to hear you’re still at it!

I think the test method needs to something simple,like the gang has already suggested -a direct comparison by you (no lab fees) at the same water temperature between your brand ‘x’ , national brand ‘y’, national brand ‘z’…

Make some sample panels with fiberglass and resin, kinda like a surfboard deck, say 6" x 6".

Weigh out same quantity of your wax ‘x’ and theirs ‘y’ and ‘z’, rub each wax onto a sample piece making similar sized bumps. Use the same amount of wax on each sample.

Submerge samples in a large pan of water that is in the correct temp range for that temp wax. Leave in there for 5-10 minutes so glass, wax, and water are all equal temps. Record temp of water.

Put out samples, place on table, run three fingers similar pressure accross the samples and determine which one is least sticky, more sticky, and the stickest. Record these results between same temp waxes.

Repeat at each water temp range with similar samples from yours and theirs.

Now you have ‘profiled’ your wax against the competition. Now you can steer your clients towards which of your recipes will do the job or modify your recipes to be ‘right in the ballpark’ for common temp ranges in the wax industry.

I don’t think being any more scientific is really worth it. As long as the wax performs predictabily and is not too expensive, no one will care about its exact glass transition temp or coefficient of friction.

I hope the best for your venture! I’d take a sample if you’re still offering. -J

Besides the printing on the label, I thought the only difference in temperature waxes was the scent. Coconut-tropical, berry/spice-cool. Lol.

Hey J,

Thanks for the advice and continued support mate. Definitely needed to clarify this temp situation and thanks to you and the boys here, I finally have my head around it. I really like your ideas for testing the waxes so I will (try to) keep this reply short and sweet but absolutely say I am going to try as you suggested as whilst I love to get in the water, the idea of testing loads of different formulas is not the most appealing what with removing the wax and re-applying about a hundred times lol. I want to get as close to the temps that I want under “lab” conditions and then take the waxes I think are temp ready to the beach and then get them tested in the water. Its taken me a long time to learn how to make proper wax rather than the coconut oil / pine resin nonsense but ridiculous as it sounds, when I was making comparisons to other waxes, I was comparing the labels (cold, cool, warm, etc.) of similar waxes rather than looking at the water temps. I should of thought about it a bit more really ha. I’ve also learnt a lot about what the wax companies tell you and what actually goes down with the waxes so I should never have really convinced myself that they all had Einstein on the payroll!

I got some new additives today so I am going to be running some more tests with these and if I’m happy with them (and I think I will be), I will start getting samples out in the next 6-8 weeks so shoot me over your address and I wil absolutely get you some in the mail. Should say too that I got so busy during the mold thread that I didnt get time to reply and the longer I left it, the more embarrased I was to go back to it. Having said that, that thread was a big help too so I am going to send samples out to all the boys who helped me on there too. I’ll pop over to the thread in the next few days, just dont want to bombard the front pages of the forums with wax threads! lol. Wow, that was a longer reply than I anticipated - sorry.

Thanks again bro and hope life is good for you.