As a garage hack who uses UV poly, I could see this not only being ridiculously useful in terms of mess, but also possibly a way to conserve resin even further. Do y’all think the resin left behind on the tarp would be clean enough to be used in another lamination?

I was always taught that a cheater coat was put on at least while the lam was still somewhat soft, if not immediatly following the lam. I always assumed the reason was a better bond. Most guys that use a cheater coat in my opinion do so because they are afraid they may have pulled too much resin off the board. My experiences with cheater coats has only been with Poly and in "busy" surfboard factory atmospheres. Originally I was taught to do an adequate lam, so no need for a cheater coat. But after being around differant factory setups I saw that quite a few laminators applied a cheater coat on every layup. I think your table method has merit and I certainly will give it a try at some point. I usually lam five at a time, first two then three or vice/versa. So room and wetout of the multiple layers, rolling them up etc. seems to be too much work given my circumstance. I can dress the bottom of two or three blanks. Lay them up. Move them off the rack. Do likewise to two or three more. Flip 'em. Grind 'em. Lay up two layers on the deck. Hotcoat the deck. Flip 'em. Hotcoat the bottoms. The only extra steps being that as each blank is moved off the glassing rack it spends a few minutes under UV. I lam several at a time, because I shape several at a time. I like to concentrate on one phase of the build at a time. Instead of jumping back and forth from shaping to glassing, to shaping. If I do a good tight lam on the right blank; I get a strong, light board. I think that the reason alot of guys have problems getting a good wetout with Epoxy is that they haven't learned to listen to their Squeege. It'll tell when you're getting enough resin on. Lowel

Yeah. Unfortunately I know their sort of M.O. oh too well…

Thanks anyway…

I actually have a lot of fun dealing with these “half wits”…

I’ve had my credability questioned by this group of idiots ever since I joined Swaylock’s

I guess they feel it’s their sworn duty to guard the gates of Swaylock’s…

Woahhhhh… Do I ever feel intimidated,ha,ha,ha,…

The real comedy in all this is the fact that this and many other composite construction technologies that these half-wits claim as their “new” and " proprietary " methods are simply washed down methods that have been used by the aerospace, automotive, race boat building industry etc. for decades…

Finally In regards to these people… A good friend once said to me…

“When it comes to a battle of wits… They’ve come unarmed…”

VanHelsing.

End of hi-jack-rant … Sorry Dwight…

There isn’t enough resin on the plastic sheet. If there is, you poured too much.

But, the resin drops left behind on the plastic sheet, can be scraped up and used to spot fill, like air bubbles at the leash plug, or some extra resin at the nose lap.

Nice

Yeah… Sorry to ALL here…

My bad… Getting angry is not the answer … Is it?

I tried to pull my last post but it’s trapped now…

Time to take a break from this place and reconsider…

**you threaten me in private message and you want an apology? **

<div class="author-pane-name-section">

<div class="author-pane-line author-name">

<a title="View user profile." href="http://www2.swaylocks.com/user/vanhelsing">VanHelsing</a> <span class="author-pane-icon"><img title="User offline. Last seen 1 hour 59 min ago." src="http://www2.swaylocks.com/sites/all/themes/zen/swaylocks/blue_lagoon/images/user-offline.png" alt="User offline. Last seen 1 hour 59 min ago." height="7" width="5"></span>

</div>

</div>

<div class="author-pane-line author-joined">

<span class="author-pane-label">Joined:</span> Jul 20 2012 </div>

<div class="author-pane-line author-posts">

<span class="author-pane-label">Posts:</span> 115 </div>

<div class="author-pane-line author-points">

<span class="author-pane-label">Points: </span> 131 </div>

<div class="author-pane-icon pm-link"><a href="http://www2.swaylocks.com/privatemsg/new/1025526">Send PM</a></div><div class="author-pane-icon pm-link"> ** 6 mnths and you are deciding who should be here**</div><div class="author-pane-icon pm-link">**

**

</div>

</div>

</div>

Well at least you have my apology .FWIW…

And I’ll say it one more time…

I’m sorry to ALL here for my remarks… I should know better.

VanHelsing.

well thank you and i do apoligise for being a bit staightforward but thats me take it or leave it

mybe we could try geting along i does work.

cheers huie

Got to say Huie is a doer, and a thinker, and my elder! Van Helsing, your right, all this stuff is essentially watered down crap from the aerospace industry. Yeah you attacked me in a pm, but that was a while ago, and I really am over it. I guess you misread us thinking you are here to do battle against us like you name suggests, but I can assure you I am not a demon.

Mcding is right, you “got to listen to your squeegee.” Everyone occaisionally airs out a lam because of catalysation or draining, and cheaters have become the norm in production settings, because not only are you pushing the resin around, but orienting the cloth, and taking out the read, and to do so you have to push and pull a bit, and that can air it out like Phillip Rivers on a bad day.

This thread has been affable and informative for several members. Perhaps we could keep it that way as well as on-topic.

I would prefer not to petition moderators to delete specific posts that disrupt the course of the central discussion. Doing so would be as banal as the interruptions.

Getting back to the wet out table, if the cloth has a reasonable resin load when you pull it off the table you don’t really want to pull any more out with perf ply, do you?

Isn’t perf ply used for vac bagging? Dwight’s method doesn’t use a vacuum or perf ply.

True, but I am talking about vacuum bagging.

Dwight, Great thread! Could you discuss how you prepped the blank before laminating. If you sealed the blank and what method(s) you used. BTW that 44" S is some good “stuff”. Thanks, Dave

Dave,

I seal with fast N final. I plan to stop by the cold stroke and say high. I’d love to share stories. You’re bringing a board to my bud Dennis.

Dennis has watched me build a few boards.

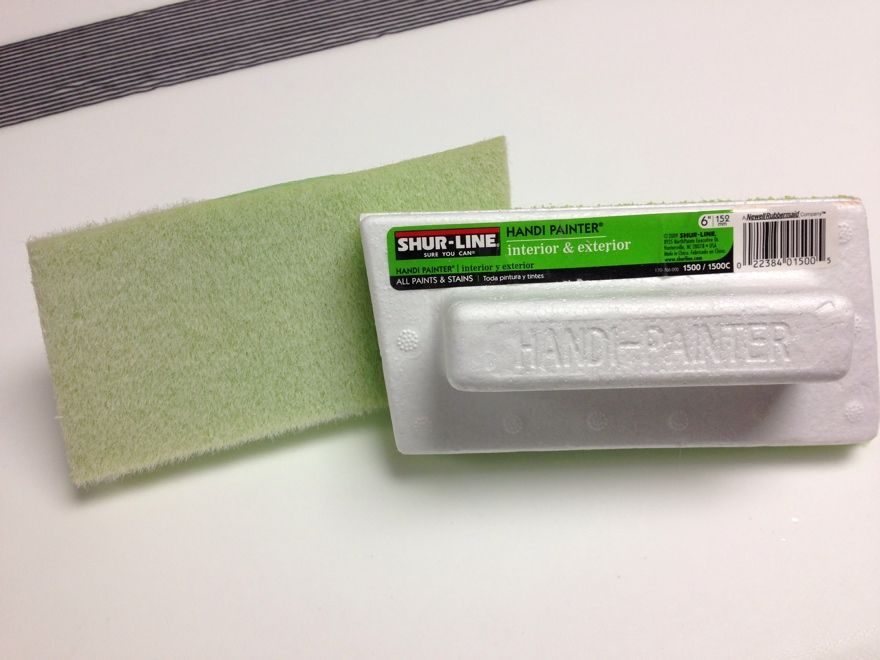

I had some private message questions about pin holes and how I hot coat. This is my secret weapon.

Pushes resin around like a super hero and no brush hairs. Kicks ass on the rails. Only drawback is the cost. $1.99 each (Home Depot) versus $0.50 for a paint brush. But worth it for this hack.

thanks for posting, I’ve learned a few things from this thread!

so at what point are you doing your cheater coat and hot coat? are you laminating booth sides first then doing this or one at a time. Im tempted to give it anouther go but my first effot had pin holes that were a right pain in the ass to get rid of!

cheers charlie