For those of you who were waiting for this, sorry for the delay as I’ve had some distractions.

I really hope this thread helps those budget back yard shapers who are curious of some simple mods.

First off, this is the stock Hitachi and I found it on Ebay for about $60 + ship. Pretty good deal.

This has been the new generation workhorse power hand planer in the surf industry.

I did 3 basic, yet very fuctional MODz to this guy, 1.) Heavy Duty power cord install 2.) Base & Shoe resurfacing

and last but not least 3.) Handle relocation and positioning

This image shows the handle already cut, and we’ll touch on that in a minute, but more specifically I’ve installed a

heavier gauge 3 prong power cord. To do this with the handle relocation, you’ll need to drill out a hole on the top of

the handle. Gauge the hole you drill by the thickness of the rubber collar on whatever cord you desire. Then re route

the power cord wire behind the trigger assembly(tight fit). If you wish to leave the handle stock position, no worries.

Front shoe has been modified in the respect of eliminating hard edges and rounding corners as needed to allow for

faster performance planing while minimizing the chance of gouging the foam with the factory stock hard edges and

corners. Also the blade side of the shoe has been honed out and smoothed and polished to help flow of discarding

planed material.

The same has been done to the rear base plate. This all was accomplished with a air powered angle grinder and

finally smoothed and deburred with a scotch brite attatchment to the grinder.

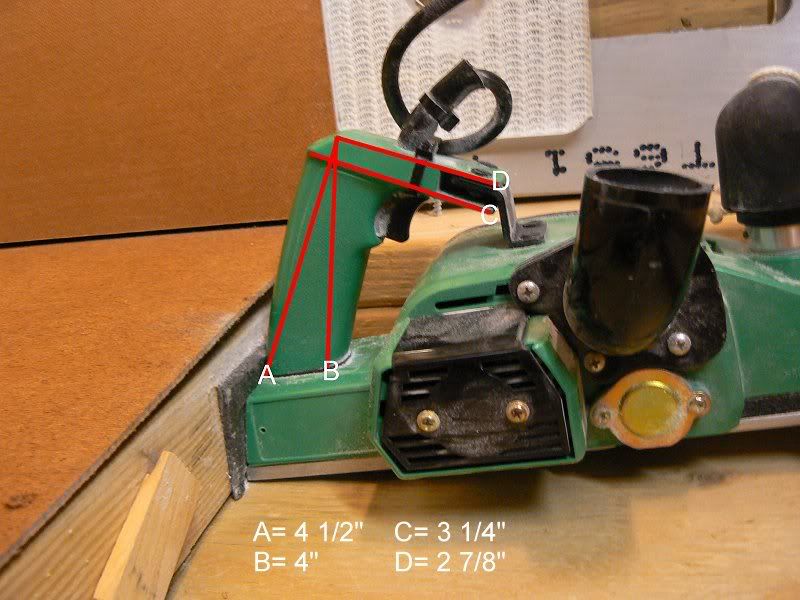

For the handle relocation, you’ll need these DIMS. Use these as a reference, as they were taken from a Clark Foam

modified Hitachi, but of course adjust as needed.

Stock and newly modified handles.

Finally I used gorilla glue to tack the modified handle in place, and then used a 2 part 3M epoxy bead around the base to hold it in place. Then fashioned a metal bracket and adheared the same way to ensure stability.

Overall the Handle mod made me the most nervous, but was very easy and is absolutely sturdy as one could possibly hope.

More on this to come soon.

I encourage other planer mods whether hitachi or not as feedback!

Tyson W Dougherty

Dave_D

Dave_D