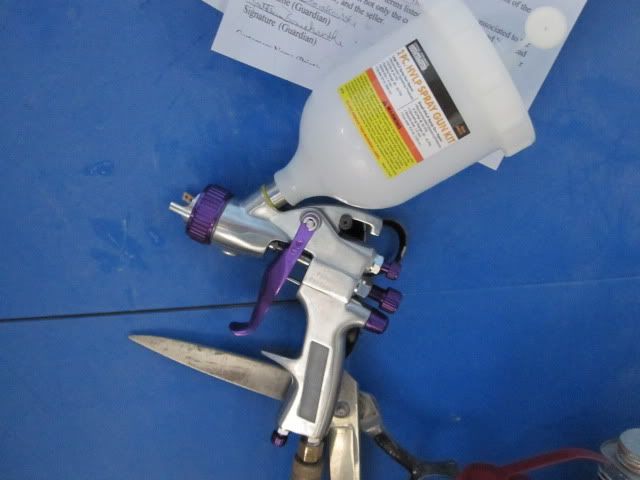

My good friend Rick DeJainne or known as rdj asked me if I wanted to try Matt Cambell's aka Resin X new gloss coat system. I said sure Rick and I purchased a 5 gallon bucket of the stuff and had it delivered to my shop. This is the first time I ever spoke to Matt and he is a great guy and told me the steps to applying this stuff. This is compatible with poly or epoxy by the way. The board is an Ice 9 blank with epoxy resin for lam and hot coat, the pinlines are just plain old Wal Mart acrylic craft paint applied with a brush straight out of the bottle. If you are doing pinlines with this gloss coat you will have to do a second hoat coat over the pins since the product is very thin. Sand to 320, wipe board down, run tape along the length of the board to pick up any particles, Tape off leash plug and fin boxes mix the uv clear with the catalyst and water and you are ready to go. Rick being a chemist got the ratios spot on for smaller batches. I mixed 20 oz of uv clear with a 1/2 oz of catalyst and a 1/2 oz of water, it was easier to measure the water first and add equal amounts of catalyst to the water and mix it before adding to clear. I used a hvlp Harbor Freight spray gun pictured but I switched to the primer tip that came with it, 2 guns came with this set $39.99 plus $10.00 insurance for a year. Sprayed 3 single coats going perpindicular to the board not length wise overlapping each pass as I go making sure to get everything wet but not soaked so you have no runs. After each coat I waited a minute before applying the next, it took a total of 5 minutes to spray 3 coats. Let the gloss smooth itself out and dry, flip the board and repeat the process, I also sprayed the rails with thin coats as I went along with each coat.If you have any runs wet sand with 1200 sand paper then just medium compound and polish and the pics are what you get.You can use a brush but I suggest you only do it on short boards because this stuff dries quickly. Any other thoughts or questions hopefully Matt will chime in with his knowledge. Much easier and faster then any gloss coat out there and it's even faster if you don't put pinlines for the added hot coat. Just my 2 cents on this stuff I'm very pleased with it and will be using it from here on in Thanks Tom

My good friend Rick DeJainne or known as rdj asked me if I wanted to try Matt Cambell's aka Resin X new gloss coat system. I said sure Rick and I purchased a 5 gallon bucket of the stuff and had it delivered to my shop. This is the first time I ever spoke to Matt and he is a great guy and told me the steps to applying this stuff. This is compatible with poly or epoxy by the way. The board is an Ice 9 blank with epoxy resin for lam and hot coat, the pinlines are just plain old Wal Mart acrylic craft paint applied with a brush straight out of the bottle. If you are doing pinlines with this gloss coat you will have to do a second hoat coat over the pins since the product is very thin. Sand to 320, wipe board down, run tape along the length of the board to pick up any particles, Tape off leash plug and fin boxes mix the uv clear with the catalyst and water and you are ready to go. Rick being a chemist got the ratios spot on for smaller batches. I mixed 20 oz of uv clear with a 1/2 oz of catalyst and a 1/2 oz of water, it was easier to measure the water first and add equal amounts of catalyst to the water and mix it before adding to clear. I used a hvlp Harbor Freight spray gun pictured but I switched to the primer tip that came with it, 2 guns came with this set $39.99 plus $10.00 insurance for a year. Sprayed 3 single coats going perpindicular to the board not length wise overlapping each pass as I go making sure to get everything wet but not soaked so you have no runs. After each coat I waited a minute before applying the next, it took a total of 5 minutes to spray 3 coats. Let the gloss smooth itself out and dry, flip the board and repeat the process, I also sprayed the rails with thin coats as I went along with each coat.If you have any runs wet sand with 1200 sand paper then just medium compound and polish and the pics are what you get.You can use a brush but I suggest you only do it on short boards because this stuff dries quickly. Any other thoughts or questions hopefully Matt will chime in with his knowledge. Much easier and faster then any gloss coat out there and it's even faster if you don't put pinlines for the added hot coat. Just my 2 cents on this stuff I'm very pleased with it and will be using it from here on in Thanks Tom

Does this save sanding time? How is the clean up with the gun? Are you using solvent to clear the gun?

tblank

There is no sanding if done right, if you have a drip you wet sand with 1200 then just medium rubbing compound and then polish. This cleans up with warm water, when done spraying put extra in a seperate container for next time and clean gun with water

Tom

No Sanding??? I’m all for it.What is cure time? Clean up is good…no MEK! How’s the cost on resin compare? Thanks for getting back.

ps. That light blue triple stringer on your site looks nice, great outline. Specs?

Tom,

Beautiful board! We have been testing this stuff for Matt for a few months and it is definitely neat stuff! It is unreal how fast it sets up and how hard it gets in such a short time. Unbelievable that it cleans up so easily with water.

To clear things up a bit the product is not ResinX but was introduced by Matt Campbell who is the developer of ResinX. It is compatible with Poly, Epoxy and ResinX.

regards,

Dave D

tblank,

Your welcome, yes no sanding just medium rubbing compound and polish it, you use very little, this board is 8 ft and I used around 20 oz for the entire board thats with 3 coats you can do only 2 coats if you want, it adds very little weight and cures in a couple hours for flip time it hides weave burn great. as for the price since Rick aka rdj is a chemist Matt valued his opinion on this stuff and gave him a special one time rate you can e mail Matt at cambellscoatings@gmail.com for pricing. It's more expensive but you use so little that a gallon goes a long way, plus your saving on sand paper and a lot of time. Thanks for the board compliment the triple stringer is 8' x 23" x 3 1/2 " . I'll send you the outline on resin paper if you want.

Tom

Thanks for clearing that up Dave I worded that wrong, sentence structure is not my strong point

Tom

is it available in less that 5 gal volumes? Looks like even I could apply it with good results.

Hi this is Matt Campbell.

We sell gallons but do not brake the catalyst down only to pints. A pint is enough for a 5 gallon kit. Fiberglass Hawaii may be breaking down the catalyst for gallon size kits. There are sheen choices as well Gloss, semi-gloss, satin, flat and dead flat.

This product has been extensively tested over the last couple of years with great succes. The product has endured over 2000 hours of of QUV testing along with constant saltwater spray. Without peeling, cracking, or yellowing. This product is socked with UV inhibiters can also be used to seal a PU blank to slow down the yellowing of the blank. Even on a paddle board that was heavily used and draged around the Beach for 18 months nothing chipped peeled or cracked. The prouduct also seals and hides weave on sand throughs. Like Tom said, it really goes a long way too. Adds very little weight. If you catalize the material it can be simply put back into the main bucket and get re used later. I have had something like 6 different versions of this sense I started development. We Just kept on making it better.

Some people really like the product. It is a little more unconventional to surfboards but many people in other industries use products that are applied to like this with great succes.

I’ll order some from FH. Thx

How much time at what temp to I have to work with? Roll it with a foam roller as an option? Quickly walk it out with brush? Or only spray? And how safe?

Greg

Matt said optimum temp is 75 degrees, my shop was around that temp when I tried it. I tried a sample with a foam roller and it puts it on to thin and if you try to tip it off with a brush it drags cause it sets up quick. I did try 2 coats with a Purdy Sintox brush on a board with success but you have to work in 1 foot increments and put it on pretty thick and work quick, you cant go back and walk it out or it will drag. Best results are with a spray gun, I lay one coat down to where it looks completely wet, wait a minute and repeat wait a minute and repeat. The reason I wait one minute is the coat starts to set up and stops flowing out but is still wet enough to soak in the second and third coat. when all 3 coats are down it all levels out and gets very smooth and if done right just medium compound and polish, if you have a run wet sand with 1200 before compound and polish. It's water based but I still wore a mask when spraying and clean up with warm water, maybe Matt can chime in on the safety data. Hope this helps

Tom

Greg, this is about as safe as it get's and green too. It's a waterbased product. Not even a true Waterborne, which are higher solids. I would honestly like to make a higher solids version for more filling capacity in deep scratches but it might flash of to quick in dry climates plus people like it the way it is right now. You do still need to wear a mask when you spray anything. However you can handle it all day long with the lid off the can with no mask or offensive order. Not only that but you can re use the product meaning that there is very minimal if any environmental waste. This the kind of product even epa types in Ca. are stating as a great alternative in clear coat markets. Way before the auto industry had to get waterborne OEM compliant I have been working on this kind of tech in other industries and trying to create a Marine version. I have made some of these coatings that can even work on top of powder coat surfaces for added protection. The Catalyst stands to have the most danger if it gets in your eye. That is only 2% of the product and you cut 1:1 with water to break it down. To get the best UV protection you want to have 3 coats on it, which includes sanding after two coats. Best results are spraying the product. You should spray about 5-6 wet mils per coat. If your board is machined perfectly you may want to tape of the rail as to maintain that perfect edge in the back. A 50/50 type rail would not need to be taped. Tom said he waited a minute to shoot the second coat. Depending on how the coat flashes off, you may want to wait as long as 15 minutes. If you have imperfections you can also go lower than Tom's suggestion of 1200 grit and go to say 800 grit. to get out deeper issues. You can also touch up areas with a gun then use sand paper to blend areas in easily. Note this is only Top coat. It is NOT a structural type resin for building composites. This is a very safe alternative to Linear Polyurethane or Polyester Gloss because solvent is not the carrier. Water is. What the catalyst does is keeps the waterbase from reactivating in the water and makes the product that cures out very hard. Also Note at 70 degrees and 50% humidity you should let the board sit 3 days before going into the water. After 7 days the product is even much harder. You can brush the coating out; a foam roller is a bad Idea. Spray provides the best possible finish and gives your air brusher more work helping the economy.

where can I get this product in so. cal.?

and does anyone know the price

I’m def going to try it. Fiber glass Hawaii. But no idea on the price.

Hey Huck, you could get it from Fiberglass Hawaii in Ventura and they can ship it to you in a day or you can order it direct from C3D industries at 248-830-4122. I can not say exactly what FH is selling it for with the catalyst. You are going to need to call for pricing from either one of us. Like I said before they may be breaking down the catalyst into smaller quanties. Which is going to be nice for the customer. We only sell the catalyst in pints because we don’t want to deal with breaking down into smaller quanities. A pint is enough for a 5 gallon pail. The product has at least a 2 year shelf life and there is a big insentive from either one of us to by 5 gal. instead of gal. FH is all set up to make different sheens too.

Hey Guys

Australia????

Cheers

And Europe?

Not at this time as far as distribution goes yet, but we might be able to get it there. However something might be happening soon in both those area’s.

::