I’d like to have a vaccuum bag set up and the experience to work it properly.

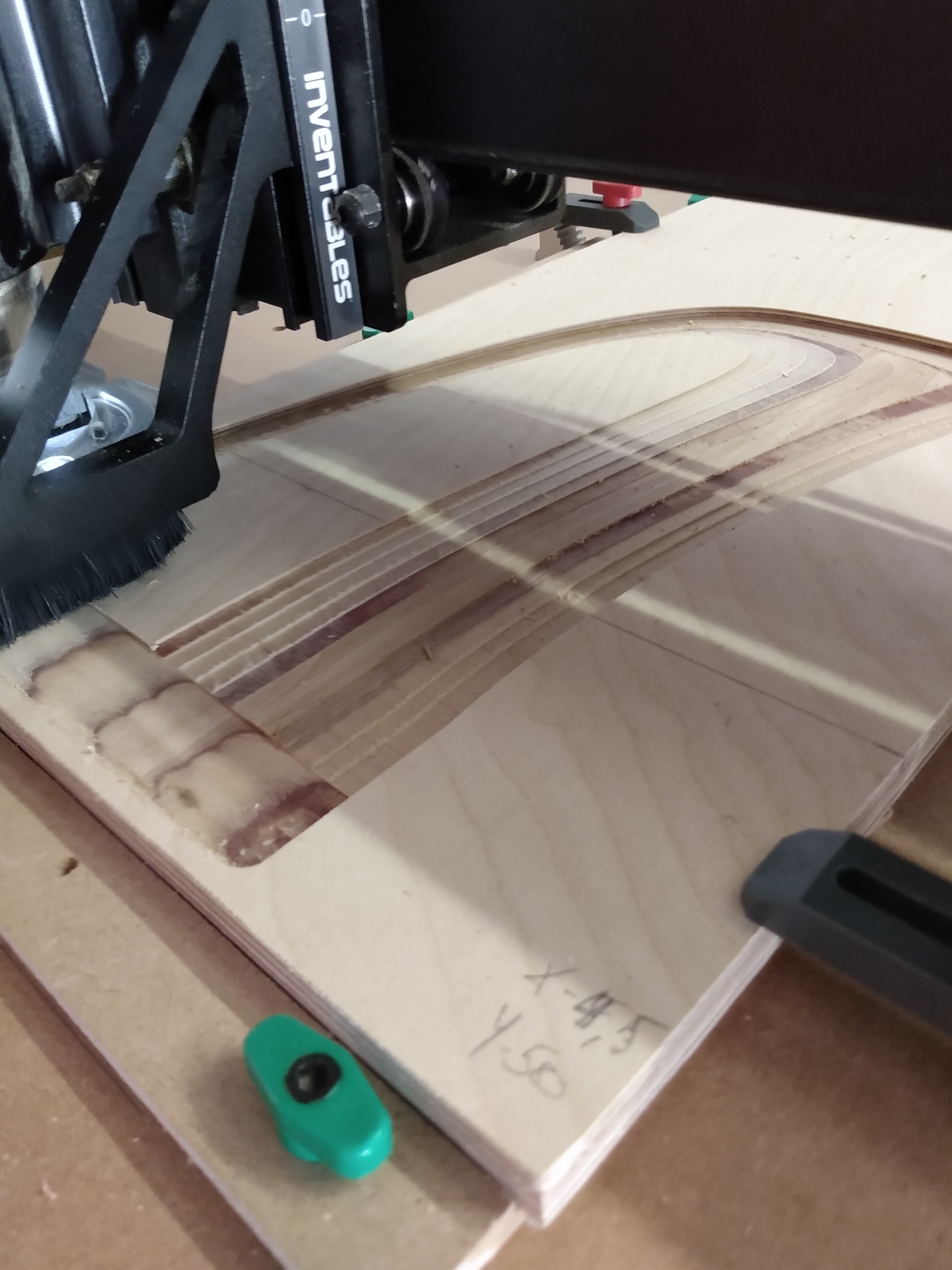

Generally the wood for my fins first go through a table saw, then a jigsaw with a metal hacksaw blade to cut out the outline.

Foiling, I Mainly use a 4.5 inch angle grinder, with Flap sanders of various grits. Though I will use some flexible disks, often backed up with worn cut off wheels of various diameter to get a certain amount of flex going.

The 15 amp Router Speed controller is imperative with this tool to dial in the speed for the wood being foiled.

I find I rarely use my Milwaukee on fins, especially multifins, but do have some old powerpads reduced in diameter.

A contour gauge helps me eliminate flat spots in the foil I can’t see properly with the shadow method.

A dremel with a drill type chuck and tiny drill bits are often used around the halo to help epoxy penetrate and lock in. I have carved a groove in the perimeter to lay a roving halo within too. Tab reinforcement for multifins the dremel is quite handy to have, and the right angle attachment on the dremel increases the precision of the tool immensely, in my opinion.

I use an old mirror for waxed glass, and a heating pad under it to get the glass and the wood of the fin upto temperature before saturating wood or cloth on the fin, then turning it off as epoxy starts to thicken. This helps epoxy get sucked deeper, prevent bubbles, and make the cloth clearer which has always been an issue.

My Fin making has been way too many steps, and I’ve rarely built any fin the same way twice.

My current endeavors are using a tablesaw to form perfect thickness tabs to just barely slide into probox inserts without the grub screws having to push the fin against the opposite side of the receptacle, but merely keeping it from ejecting from the board. I want as much of the fin base touching as much as possible of the receptacle’s interior. I feel this makes for better performance for a solid finbone to footbone connection. Think of the load on the grub screws alone, on FCS 1 or fusion.

I mave made a fin holder fence sled to accomplish this with 50/50 foil fins, Flat sided rail fins can slide against the fence nicely. I have some 6 inch long drill bits in 1mm increments and some 5mm pulltruded carbon fiber rods to insert up into fins from fin base for tab reinforcement.

A drill press and a precise fin holding jig, would be nice to have for this process.