hi there " grasshopper " !

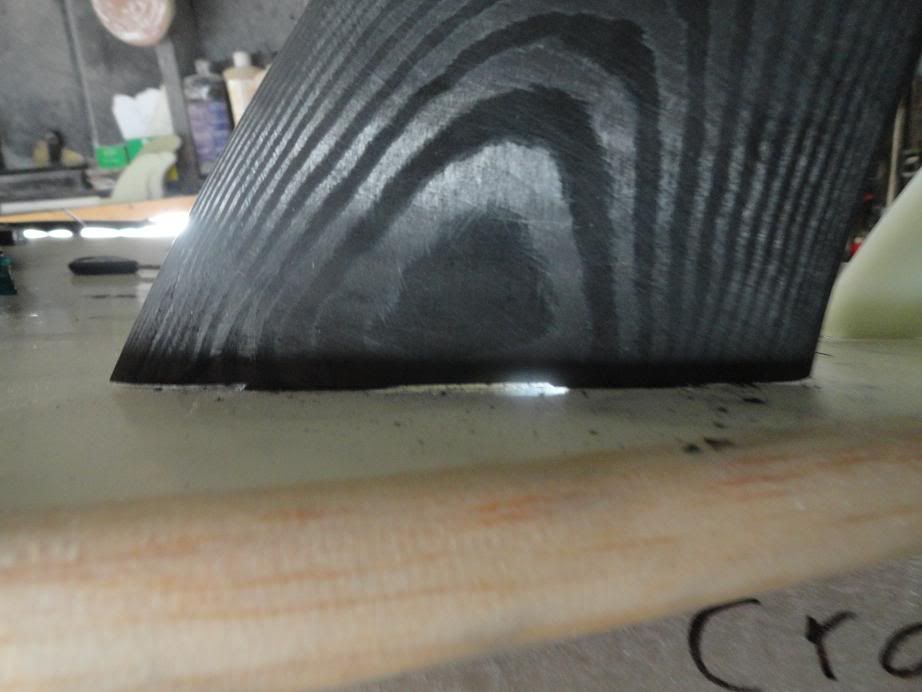

" i cant seem to get an even cut between the two tabs "

yes , welcome to my world! it ain't "easy" is it [despite what some may say ...they are usually the ones who haven't MADE any ! lol , etc]

Anyways ...

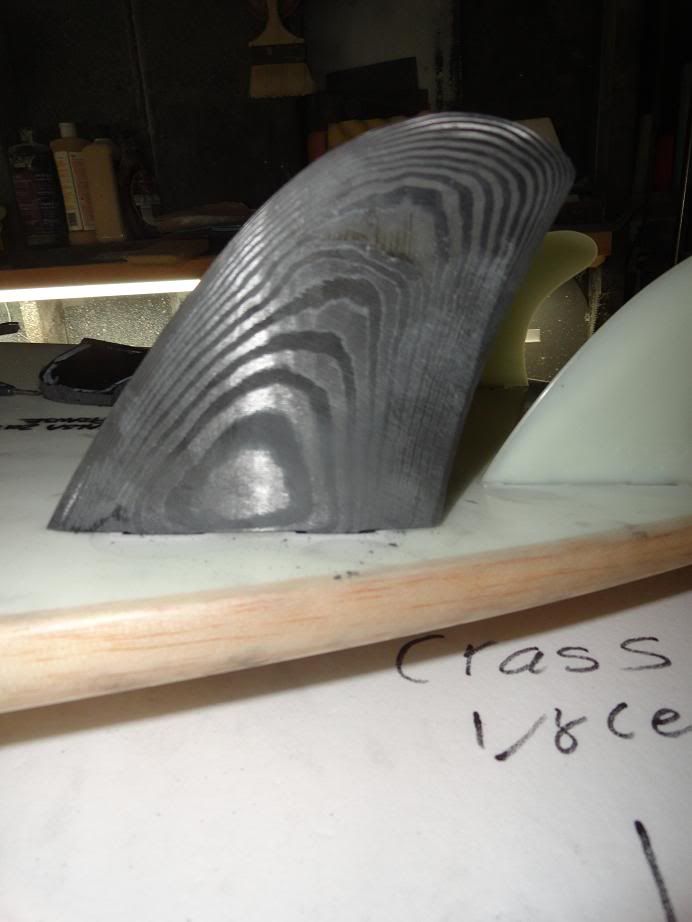

......It's actually reassuring for me , to know that , after making nearly 500 pairs of fins over the last ? however many ? years , I am not the only one who has problems getting the area between the tabs 'perfect' ...(it's one of the reasons I'd like to have had 'proboxes' on all my boards , much less fiddling / fartarsing around ! )

Like you , I also cut them out with a jigsaw with a carborundum blade .

Therein may lie the problem . Hard to get it perfectly perpendicular , handholding it , I find ? [....but maybe that's just me , eh ? ]

I know 'Silly' [ Paul Cannon ] typed once that he uses the much finer-bladed scroll saw , giving more control. I , however , don't have one ...yet.

So, after cutting just OUTSIDE the line , I have to [tediously] file down to the line , to even it up . Yes , it takes TIME ! I clamp them to the kitchen bench , and carefully file away .

I hope 'ruckusman' covers this in his 'fin foiling' video ?

It will help more to actually SEE it , rather than just 'talking' [typing] about it !]

It's really encouraging to me , to see someone else making / having a go at fcs fins ... good on ya mate , keep up the good work !

....and ....

...how about a ride report on how they go ?

cheers !

ben , the fintinkerer