When people step into a forum /site like this, make alot of noise etc. they are usually full of $#!t. That appears to be the case with holderin. Gave him the opportunity to "put up or shut up" and he promptly ignored me. The guy's full of shit! Lowel

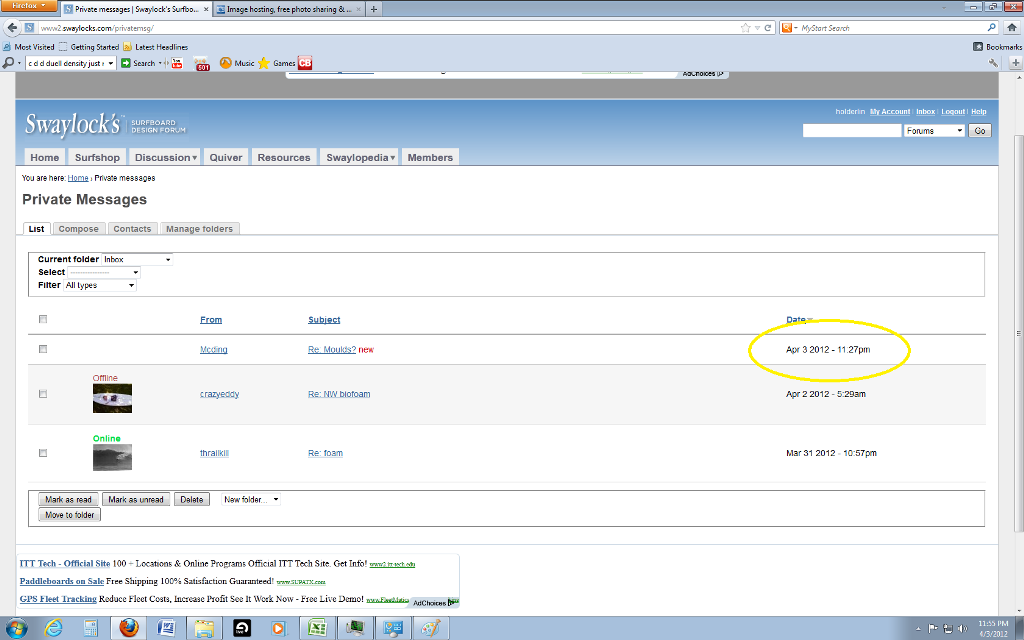

You never PMed me liar.

bullshit!

Great sounds awesome. Good luck with that.

I don’t know

So, the company that was interested went out of business? I see.

I’m a materials scientist. I know how to formulate and process rigid structural foam in ways that many others do not. This, and an interest in blanks, is all I claim.

I will be sure to send you a sample. Maybe I’ll actually come down and watch you shape it, but then I’d have to post pics on here. Now that would be comedy hour.

[quote=“$1”]

[quote=“$1”]

Great sounds awesome. Good luck with that.

that was in answer to dead shaper not you

I don’t know

what about supplying foam to the surf industry good luck with that

[quote]

So, the company that was interested went out of business? I see.

you have no idea what your talking about

[quote=“$1”]

You sent that 20 min ago in response to my post saying you didn’t PM me.

[/quote

wow posting up private messages low form that?

i would not bother lowel how the fck is this guy gona get a decent plug to gether let alone the rest

OK.

If it’s really so offensive that I would come in here and claim the know how to make good foam, I’m really sorry.

It should be noted that there’s an entire industry where people formulate and synthesize foams to solve a multitude of problems, many of which are far more complex than moulding a curved plank of uniform density and hardness.

I really don’t know why this would piss someone off. It’s not like I’m rolling in here talking shit claiming to be a badass surfer and shaper.

Actually I’m starting to visualize Huie as the surfer on Angry Boys, and it’s getting amusing. Aussie’s must be really proud of “their” foam.

GUYS...........HELLO...........Why not take Holderlin at his word? What IF he can produce as high, or higher quality blank, than is presently available? Is that a bad thing? The proof is in the product. I'd like to see what he can do. It's not like he's asking for investors. The question is, ''Foam. How do you like it?'' I had my say, about foam in general, what are your comments about foam?

Aussies are a great breed of folk.

They back up their mates.

Like New Yorkers, if they think you’re full of sh-t, they’ll tell you so.

OTOH

I don’t see the merit of attackng somebody until I hear what they have to say or offer 'on an OPEN FORUM.

The creation of poyurethane foam ISN"T exclusive to surfboards. Even Clark Foam had a program offering sheet foam in densities ranging from 2 lb to about 20 lb.

In fact 6 to 8 lb. polyurethan sheet foam as been used quite a few times over lighter density foam to create surfboards, sailboards and no doubt some SUP’s. Isn’t that ‘dual density’?

Isn’t bonding PVC foam, cork, Divinylcell/Airex/Cleducel or the skin of a Morey Doyle, Mason & Smith, other brands of soft boards, dual density?

Wasn’t the manufacture of the original cross linked polyethelene roto molded “Windsurfer” dual density?

**Ice NIne tried and went out of business. Rogers, Foss Foam, East Coast Foam…no doubt some others have come and gone. I can’t confirm if Foss or someone like that didn’t try hard foam in the early days. When I first started back in the 60’s we bought cheap rejects from Greg Noll down in Hermosa. G&S also blew their own foam. Jeff White poured their own foam in Summerland. A bunch of other guys poured their own. **

None of them were Australian. At the same time there were South Africans, Europeans, and South Americans working and experimenting with foam.

**This is just historical, not a put down on anyone from anywhere. **

**My understanding was that it was Hobie that nudged Grubby into creating polyurethane blanks. **

My understanding is that Midget has been developing foam for surfboards in Australia for decades.

I recall Bennet advertising that his blanks were blown using Dion Resin.

I seem to recall being told Ted Wilson (Fiberglass Hawaii, now partner in U.S. Blanks) sent containers of resin to Australia that was used in the production of Burford Blanks or perhaps it was later day Bennett. Not sure which one.

**

I thought this thread might actually discuss some facts about polyurethane foam with some merit. Things like:

1. WHAT CAUSES “SHRINKAGE” POLYURETHANE BLANK?

2. WHY DOES GASSING HAPPEN?

3. IS THE FORMULA “REACTED” BEFORE SHIPPING ELSEWHERE TO BE BLOWN?

4. WHY DO THEY CALL IT BLOWING FOAM?

5. HOW IS “DENSITY” DETERMINED?

6. HOW ARE INDIVIDUAL PHYSICAL PROPERTIES OF P.U. FOAM DETERMINED?

7. WHO ACTUALLY DEVELOPS THE FORMULA THAT SURFBOARD BLANK FOAMERS USE

8. WHAT PERCENTAGE IS RESIN THE MAKEUP OF AN AVERAGE BLANK?

9. GIVEN THE SUPERIOR MOLECULAR LINKAGE OF EPOXY VS PU, OR EVEN VINYL ESTER LINKAGE VS PU, CAN BLANKS BE ‘BLOWN’ WITH THOSE MATERIALS INSTEAD? IF NOT, WHY?

10. WHAT DETERMINES WHITENESS IN THE FOAM?

11. ARE BLANKS UV RESISTANT? HOW?

12. CAN CELL CONFIGURATIONS BE MANIPULATED TO WITHSTAND GREATER LOAD BEARING, LESS RESIN ABSORPTION, LESS WATER INTRUSION, ETC. . TO WHAT DEGREE?

13. WHAT DETERMINES HARDNESS OF FOAM?

14. WHAT CAUSES ‘TEARING OF FOAM’ WHEN CUTTING OR PLANING FOAM?

15. WHAT ELIMINATES TEARING OF FOAM?

16. WHAT CONTRIBUTES TO FOAM DELAMINATING FROM PE, VINYLESTER OR EPOXYFIBERGLASS SKINS LAMINATED ONTO IT?

**…I’M HERE TO LEARN, NOT PISS. I CAN DO THAT AT HOME OR BEHIND THE NEAREST TREE…

**

**

**

**

**

**

**

No need to apologize. I think others should apologize to you. This forum has always been based on helping. For sure subjects go off the rail but for most parts it’s all about sharing information and giving others assistance. This subject never should have gone out so far away from it’s original intent. If anything take it as lesson as how stupid the sufboard industry can be. So many petty grudges, squabbling over peanuts, so funny really for an industry based on toy making for adults.

Even if this guy is just some pot stirrer, which I doubt, give him some help. Real help, not history lessons.

Oops, sorry got to take the kids to school. Be back later with something positive.

Your posts are so dense I don’t know where to begin, but I appreciate all the productive feedback, from you and others.

Probably cell collapse

In what sense?To get a foam in the first place you need to have a blowing agent. I use only water—>CO2, but different low boiling organic compounds can also be used, I think the “gassing” you speak of may simply be a result of breaking cells while shaping/cutting and liberating nasty molecules.

No, when you react the resin foams and sets up, then it’s done, good to go. See below.

Blow moulding is typically used to make hollow plastic shapes/parts. I don’t know why you would do this with foam, especially given the extreme expense of the equipment, which is why I think people are misusing the term in this context. I think people are mixing “blowing” as in a “blowing agent”, and the basic moulding process to form a term that actually means something else entirely.

I have an instrument that I use, but if I wanna measure a larger sample I just weigh it and then measure how much water it displaces wt/volume = density.

You mean in the formulation? Or when you measure physicals like compression strength and tensile strength? The former consists of adjusting the different reactants, catalysts and additives to yield the desired property, the details of which are highly technical, and the latter is performed with instruments.

They may have consultants, guys like myself, or they may actually just call up BASF, Bayer, or some bigger company and have them send formulas. A few may actually have chemists, but I don’t know. It’s unlikely based on what I’ve seen and heard.

Resin is an ambiguous term. Urethanes are two component systems of Polyol+Isocyante, I typically refer to the polyols as the “resin side”, but really the total liquid volume can be called “resin”. So I’d say 100%.

This is where the non-technical person begins to get in over his head. “Superior molecular linkage” doesn’t make sense to me. Terms like crosslink density, molecular weight, hard segment morphology/content, and polymer back bone do. It’s hard to explain 8 years of school in a paragraph. In short, I would say that PU has an edge on all of those materials based on physical versatility, which can be adjusted in formulations, and the convenient fact that water—> is a natural bowing agent. If you’re going to blowing anything else takes expensive processing equipment, and I don’t think the physical properties are as good. To my knowledge the only other polymers being blown on a large scale are polystyrene and I think polyethylene.

Primarily the iso used, but resins can be dark amber as well. e.g. soy derived resins.

No they are not. This is complex photochemistry, but it’s because all the iso’s used in foam synthesis are aromatic. And EPS is completely aromatic. They will all yellow in the sun to varieying degrees.

To some extent; closed cell vs. open cell, cell size, crosslink density etc.

Crosslink density, and stoichiometry (index).

Physical subtleties, typically too low crosslinking.

“”

De-lam is all adhesion. Adhesion can be promoted in a variety of ways. Adhesion loss is a result of debonding which is related to surface energetics, H-bonding etc…

I appreciate it.

So you want to make a better blank. I think that for practical purposes lets just say your going to make a small batch or maybe just one or two. Forget distribution, rockers, stringers, etc. just better foam.

The list above by deadshaper is a good one. You are going to have to take into account the interplay of some of those listed properties in order to be successful in your mission. An example would be that lets say you could come up with better blank for shaping, uniform density, little tearing while shaping, no voids, but have it yellow in the sun quickly or have compatability issues with resins then its is for nothing.

It sounds like you have a good grasp of the chemistry and mechanics behind the foam. So a better starting point would be to improve on what is already available. You are going to have to buy some available blanks and figure out how to improve what is currently available. As an example if you take a Arctic green and make it harder (less prone to heel denting) and lighter somehow but it tears really bad while shaping then it will be a tough sell. A lot of established shapers are used to shaping at a given speed. They know how long it takes to make a given board. Their time is literally money so to slow down their process is a bad thing.

Not knowing the chemistry and not really caring to know my guess is that you can’t make a non tearing, crispy, dense, easy to shape foam. Also not knowing the terminology of foam blowing, I can only imagine that the hardness has a direct relation to the density. Making a hard light foam is a contradiction. The only foam that I ever thought was moving in that direction was the old Ice9 mowses. It had this creamy characteristic while shaping but somehow produced a pretty durable board. Definately not as dent resistant as a SB green but so easy to shape. I was always hoping they would up the blanks density a notch and somehow maintain that powdery creamy feel of planning and finish shaping of the blank but alas they went bye-bye.

For me the Surfblanks green was the best of the currently available foam. The foam was (can’t get it anymore) light, hard, white foam. Prone to tearing when planing too fast and slower to shape than a comparable US red but for a similar glassed board was less prone to denting on the deck. The comparison was a SB 7’0" green side by side with a US 7’1" EA Blue. The SB was a harder lighter foam that made for more durable end product that absorbed less resin while glassing. The same US blank in red while lighter was much worse in terms of dent resistance. I also noticed that the SB greens absorbed less resin while laminating. Arctic came along and their greens aren’t quite as hard as the old SB greens but still one of my prefered over the US. The Arctic yellows shape much easier but aren’t my choice for a durable board. Makes no sense to me to glass a yellow stronger just to make it as strong as a green with less glass. Also I’ve been liking the new US reds over the Arctic yellows.

As an after thought it might be more productive to contact the foam companies directly and offer your services. What your doing here is akin to a drug chemist asking addicts what they would prefer. And just like addicts we usually go where the supply is steady. No sense in getting good drugs if you can’t them when you need them.

Nice post.

Light vs hard is where a rigid foam formulator is really torn. To get it hard and light you have to have high crosslinking and strong blowing, both of which produce a high exotherm causing scorching induced softening in the interior.

I will say that there are some convenient coincidences where more than one of the problems you list are eliminated with one adjustment.

Your recommendation is good, and I have already been testing some available blanks Vs. my formulations and I wouldn’t have registered and posted up if i wasn’t confident in the results.

My main thesis is that being a smaller guy, with the ability to adjust my formulas in a responsive manner, I can better serve you guys, the “addicts”, as I am of the opinion that the addicts are exactly who I need to be talking to. I already develop products for someone else, and I’m content where I’m at with it.

The molecular structure as illustrated to me when comparing Epoxy, Vinylester, and Polyester resins was in terms of linkage.

Epoxy was likened to a chain link fence but even more so, as layers of the chains on top of one another linking with each other in many directions.

**Vinylester was more like the length of chain link fence but with holes in it here and there.

**

Polyester didn’t even resemble chain link but was more linear and far less linkage than the previous two. Wide gaps in its mass lacking linkage in more than one direction.

**This explanation is obviously a simplification for graphic purposes, but it has always been my understanding that high solid epoxies have stronger mechanical properties than high grade polyesters. Vinylester is the wild card in this equation being somewhat a hybrid though I use that term loosely.

**

Well then thats a bit better. We are getting somewhere. So not only do you know foam you know surfboard foam.

So great you are going to make me my dream blank. I’m game.

From my experience the core of the surfboard has always been the problem. Just to keep it level I’m talking about standard available construction. E glass and polyester resin. Such a weak link in a boards construction but that is just how it is. PU foam is easy to shape, color, and takes a resin that is cheap and available. Most consumers ask for this and are not willing to pay more for something with better materials.

So in order to make a better board my opinion is we need a better core. My position is that I’ll sacrifice some of my time to produce as quality of a product as I can. So you know what the density of an Arctic green is and for a given blank how much it weighs. Same for a US red or blue. If you told me you could produce a harder to much harder foam than the ones just mentioned but without a weight penalty but with the downside of additional tearing I would change my shaping techniques or purchase a shapers barrel for my planer.

I would argue that the harder denser foams provide a snappier lively ride, last longer, and use less resin to laminate. But then again I don’t think anyone has ever been able to produce a hard enough foam that was light enough for consumers to say that the ride was too stiff. I mean look at balsa. Never heard one person say the ride was bad, only that it was heavy.

So for the sake of discussion you tell me no problem I can do this. I can make a foam with the same density as whats currently available but with better mechanical properties, same price, or even a bit more. Then great in my book you’ve got a winner. But as a word of warning whatever you do do some testing. Ice9 came on the scene and was giving out sample blanks of their sugar foam. Just about every single one here in Hawaii went to sh*t from wrinkling and warping after glassing, people were bummed.

This thread is BS. Lots of hot air. No substance. Whatever happened to the guy who was going to make a blank out of pour foam. Remember that thread?

I agree with you Mcding, but how come you and dead are now posting in Huie bold? I think only Huie should be allowed to post like that.