Well… it’s happened. I finally scraped some cash together and made an order to Greenlight last week, and today, I officially started shaping my first board. Boy oh boy, was I excited! Got two blanks, a 510 fish and a 64 shortboard, with enough glass for the both of them. Gonna be ordering Solarez resin tomorrow, hope to get on my first shape by next week.

Here’s a little photo diary of day 1.

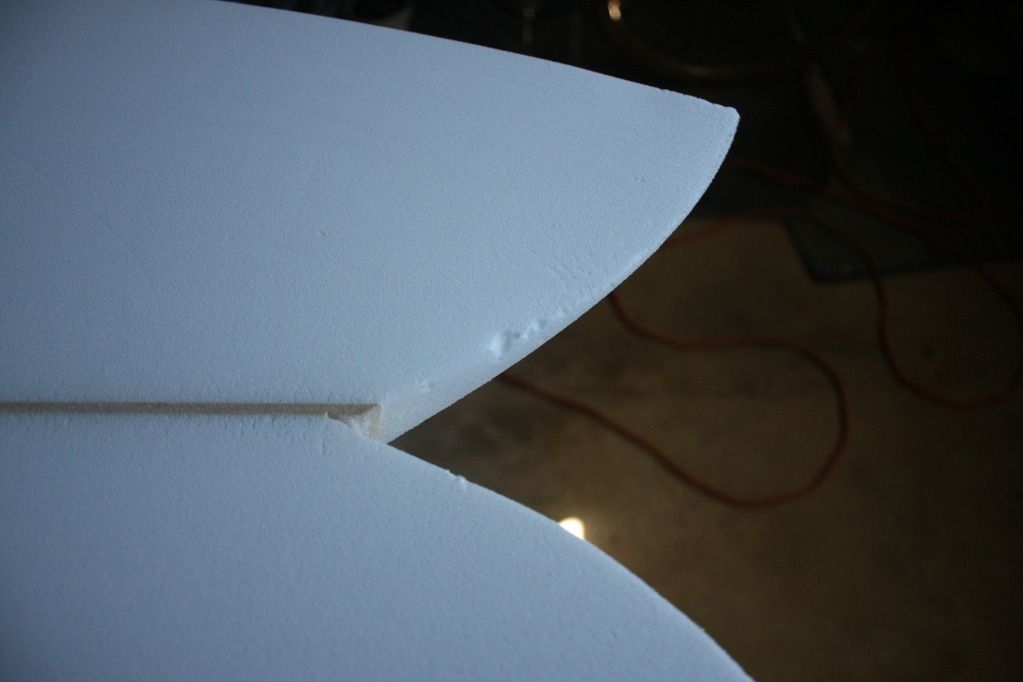

510 and 64 slugs.

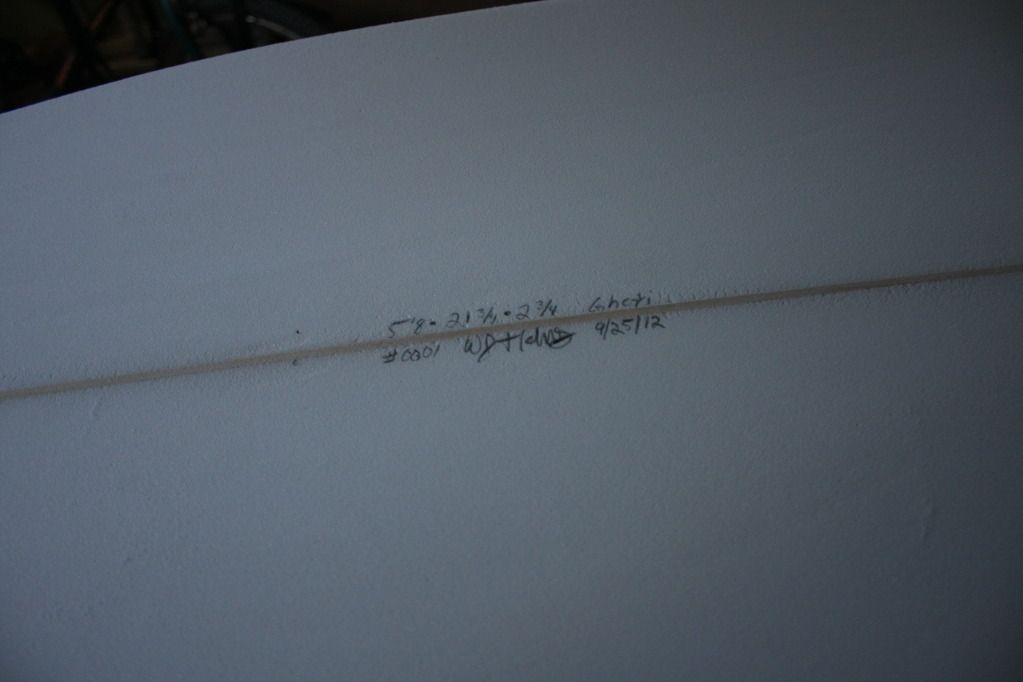

I was going to go to Home Depot for a sheet of masonite to make a nice template, but the 10 foot box my blanks were delivered in took up all the room in my mom’s van. So, I got resourceful with some old cardboard and made a temporary template (ha). The design was originally printed on plotter paper, after I designed it on Illustrator. Original dimensions were 5’8" x 22".

Cut the ouline with an old cross cut saw. Saw a Terry Martin interview a few months back saying that dull saws cut better, doesn’t tear the foam. This saw was about halfway dull, so, it was a nice smooth cut. Few tears here and there though. True the outline with Greenlight G Rasp poly carb. Nice little tool.

I have always hated cutting swallow tails (on hand planes, which I have done too many), because there’s little room to fix it up. So I try to be precise, and of course, it always ends up like garbage. Cut with a jigsaw and surformed to [proper(ish)] dimensions.

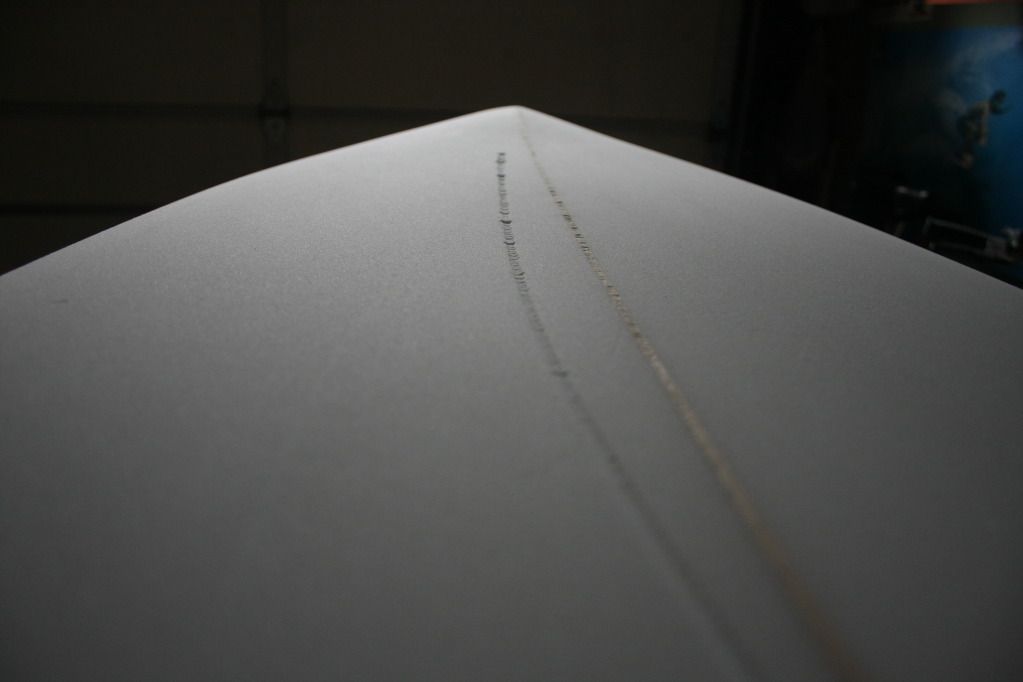

Did a double concave underfoot. Yes, I PURPOSELY put a double concave on my first board, even though everyone said keep it simple. But the G Rasp and a mini jack plane made quick work of it, and it turned out pretty nicely. Working on a concave deck to keep me locked in, Ryan Burch style.

Did one full rail today, and the bottom of the other. Other rail will be done tomorrow and then finishing touches, and I suppose it’s glass time. Can’t really tell in this photo, but the rail turned out realllly nice. I was kinda worried about that part the most, but it was fine.

Some shapers have dogs (Lovelace), I have a cat.

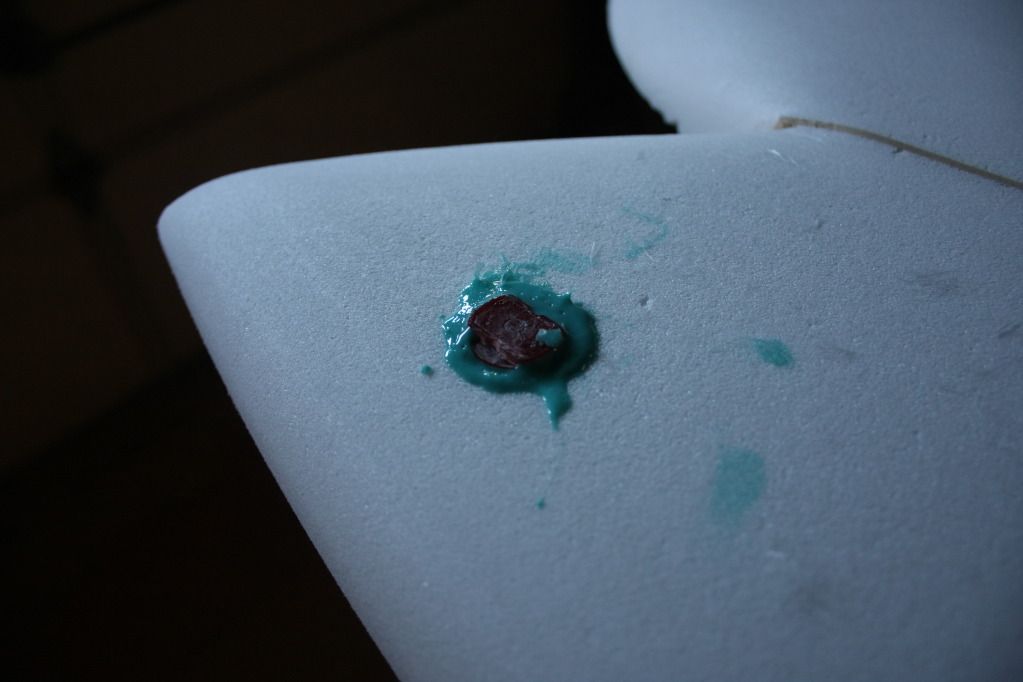

My little plane that did a lot more work than I thought it would. I always loved that tool.

So that’s day one. Hope you guys enjoy my work. Feedback, criticism, tips, whatever, is all appreciated. Thank’ee.