Folk’s - it (spoke shave) just plopped on my doorstep from -Foamez! I watched there vid so I know how to use it. But I’m wondering where, how and what you like to do with yours? The guy in vid angles slightly, and pushes from deck side nose towards wide point on stringer to then the nose flip…but if I’m interested in flipping it up, it seems logical tyto go from wide point side towards nose. Up closer of course, im just saying direction wise. I also have a 1" stanely trim plane I found at a garage sale, and a six and half inch normal block plane. So how do you work these tools?

You have to plane with the grain, so on the deck it’s from ends towards center, and on the bottom it’s from center towards ends. Unless you have some very unusual stringer wood.

You an always make some wagon wheel spokes too, that’s what the tool was originally designed for.

Hi Mike, I think the blank has a spruce stringer - cuts pretty easily. Anyway, I was thinking of trying to give the nose a cosmetic flip on deck side…probably a little on the bottom to? I’m going to plane tommorow, and get this nose looking sweet. Thanks for the heads up! Pretty k tool -gonna keep it to remember you guy’s once I start pumpin um out! some tools are k, and this is one of them! it’s a keeper.T c

I’m GLAD Jim recommended the tool bcuz the smallest plane doesn’t quite fit the flip there on deck. OVERALL -I’m impressed.

THANKS FOR TIPS!

The plan is to do a subtle/modern s deck. I’m going to scoop a curve in nose from tip to wide point, and drop the tail about 1/3 up from tips…so the meats behind center …kinda like Vaquero vid-but subtle. I’m going to set my pp on low setting so I can work it in…

Best advise I can give is that its a tool that needs to be razor sharp and the blade properly adjusted.

I got a sharpening stone in the kitchen -I’ll sharpen it- thanks MUCH.I’m just thinking of putting the blade on a low

Shave cut… so as not to ‘gouge’ stringer…

Well folk’s, I just rubbed my thumb on blade it feel darn sharp! It appears sharp already?

All of the above

Mako has good advice. Also you need to hold the tool securely and keep pressure balanced, the worst thing that can happen is having the tool roll over and all of a sudden there’s big gouges down the blank. Don’t ask me how I know this lol.

How you set the blade is up to you, some guys like an arc in center, and others cock the blade over to corner (like you do on block planes for stringers) and cut from just that corner.

On thin flip tips you can break the whole nose off too, which is why pros get the nose really close with the grinder before you start fine-sanding and using the spokeshave.

You only want to stringer plane twice. One big cut which takes the stringer below foam level, block/finish that; then a second tool that’s set on tiny cut, very carefully to leave very minimum scars. Lightly sand that off as last finish step that area.

Mike -thanks MUCH! I’ll jot that down, and all the other AWSUM tips from you -gentlemen as well. Tommorow I’m cutting in the tail kick behind the fins there. Gonna set my fronts at 11", still debating rears? I think 5, 5 1/2" up x 2" inboard 1/8" tow, fronts 1/4" tow 1 1/8" inboard 7 deg cant, zero cant in rears.

Then I cut in a single to double concaves…it’s gonna take over a day I know that much…then I’ll deal w S DECK work…thanks for the advice! It’s going to all be applied, and im extremely careful.

IMHO, this is why spoke shaves suck. You can’t control them. They are going to shave along the stringer, but they won’t true up the curve. A small plane, with its nose and tail both touching, keep the blade at the correct position to make a consistent curve. A small plane is self guiding.

Mike - I got a small 1" Stanley brand trim plane I’ll probably use for the straights on stringer…but yeah I can angle blade so it’s shallow at a corner…I just want a slight shave -just to level stringer to foam…

So I’ll have to finish my contouring w mods, and then take stringer down and light sand. Got eighty and 150 grit for finish work. Hopefully I got the right stuff! I used the same over twenty yrs ago and it works.

IMO,

The “mirco plan” @ EZF was almost 11 bucks the stoke shave? mine is maybe 4 years old me loves it.

Trained with the spoke shave, EZ to lose your job, basically put the nose in your chest and hope.

The micro plan held at 45 deg running down the nose will get things close enough to finish and me do believe with better control.

Oh and the spoke shave blade should be the sharpest it will ever be.

rock on.

is that right? Well, I happen to have found a near new ’ trim plane’

Stanley brand 1" plane…has a self adjusting screw. I can try -both? Thanks man.

Sharpen it. The cheapies from the supply houses are never sharp enough. Otherwise you’ll do more scraping than shaving. Stanley mini-plane will get you there too. $7 or $8. Alot better factory edge.

my Stanley trim plane -looks just like that! It has same screw! Thanks MUCH. I got tons of sanding to do in the am…after planing. Glad a made my 11" block! It won’t lie…

I try that 45 - thanks MUCH.

McDing & Oldphart_shaper - I’ll sharpen the blade for spoke shave as a I want a noticable flip tip and modern beak nose (thinned/paddied) …then I can run the Stanley trim plane to clean her up…the plan is to kinda almost scoop the nose from wide point to nose. But I’ll work in opposite direction w hand plane… the tail I have to drop also. Keep in-its subtle s deck. I also want rails to blend into deck 4" inboard. So I think I’ll make a jig to pencil in top rail lines… thanks for the tips guys! This board is going to be addicting!!!

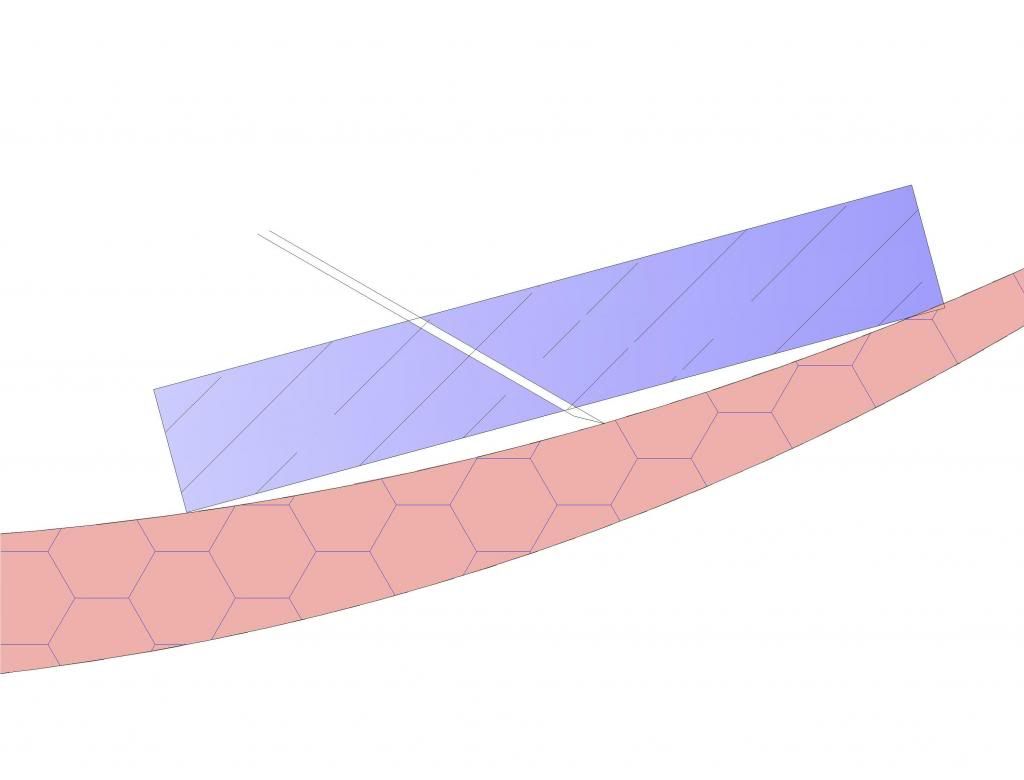

I have a coupl of these, with the blades set slightly differenty. I switch them as the nose curve tightens.

Then one of these for the flatter area entering the nose.

Oh yea, sharpen them frequently! A sharp planer is smooth as butter. A dull one rips and tears, a sharp one shaves. And don’t try to freehand when sharpening. Get a sharpening guide!

I’ve got the one on the right.

That’s because you are using it backwards!

Stand at the nose and plane from the tip toward the center.

I only use that tool for the first 18" or so.

Mine is rounded on the corners and only cuts the stringer.

Can foil out my noses to nearly paper thin!

Spoke shaves are key for tint quality finish work.

THANK YOU! I figure since my flip tip is pretty much cosmetic, it really doesn’t matter if its not truing my curves. Be cuz I am basically leaving my nose rocker curve natural for the most part…but I might put a slight flip a foot n half down from tips for a little xtra nose dive defence?

THANKS Barry! I’ll go ahead w spoke shave.