So about a month ago I broke my daily driver. The day I broke it I remember thinking to myself how good the board was working.

So now I’m thinking about it’s replacement. Last summer at the Plaskett Swayholics gathering I was very impressed with the boards CJ made using innegra- light and strong. I know my product will probably not be as light and stong as his but I figured I’d try something new. After having made 10 variations of wood compsands, this will be my first non timber product.

I got a 2 oz innegra sample and wanted to start testing. The only piece of 1.5 lb EPS I had lying around was a remnant of the the wood joint-

So I stripped the glass of the back and I’ve started my little practice tests in miniature-

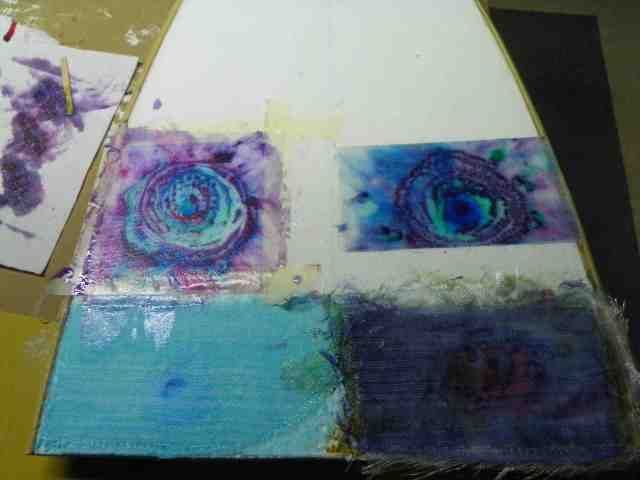

What you see here -

bottom left, first test - 2oz innegra with 4 oz over. This was not very strong. Failed the thumb test. Also, I didn’t like the tint. The weave shows too much. But it was easy to cut, really easy. It wet out easy. I’m not sure why most everyone insists you have to use a vac bag with the stuff.

bottom right- 4oz under, 2oz innegra, 4 oz over. I tried to do a little swirl and it just got all muddy. It was very strong. Infact it semed like over kill. I could feel the foam giving way under the glass though. I started to believe whatmany had written- that you can’t do a good swirl with epoxy…

top right- 2oz under, 2oz innegra, 4 oz over. OK. This seemed strong and lighter than the above schedule. Also the swirl came out much better. I was trying to get the effect of paua abalone. This might be the schdule I use on the deck…

top left- just 4oz. I wanted to try a swirl with two layers of 4 oz, as I’m thinking the bottom will be two layers of 4. This was the first layer. This one starts to look like abalone…

Now on the middle left is the second swirl added, this time with red and yellow. I don’t like it. I think not having foam to soak into made the second colors a bit muddy.

On the top I tried again using 2 oz and 2 oz innegra with tint. didn’t like it. So I mixed another batch thinking to add white tint. After I realized I didn’t have any white tint. So it’s just clear…

Anyways, all these tests I’ve done mixing 3/8’s of an ounce of resin, 1/8 being the smallest amount I can measure. All of it very rough (usin the same little cups over and over- sorry Ray). And squeegeeing it as dry as possible. Really scraping every last bit off. I asked CJ how he goat his boards so light and he said “Use little resin.” I want to try to hand lam everything…no vac bag this time…

Then I put a ittle hot coat to see final strength and the hot coat didn’t adhere well to parts of the tint. I wanted to try the next test with add F but realized I don’t have any.

Testing will continue…