My “bay” was formerly my lanai (balcony).

Time to go spackle my blank…

My “bay” was formerly my lanai (balcony).

Time to go spackle my blank…

The middle shelf is held in by wedges on both side so it splits apart into thre peices.

CMP has racks that adjust for length and height. You can make all kinds of adjustments to you rocker by changing the distance, and adding weight in the right place. you you do your lams. Then to do your fins you can get the board perfectly level in the tail area by adjusting the height on one side or the other.

Those racks are the best I’ve ever seen. He’s so far ahead of anyone else, it’s ridiculous. I use plastic saw horses, or a wooden box, but I’m able to shape boards like this.

very humble hand-me-downs. i really do need to get around to making new racks sooner rather than later.

just got finished whipping these up out of crap i found in my garage mixed with a black and decker workmate … pretty crude, but they’re sturdy.

just got finished whipping these up out of crap i found in my garage mixed with a black and decker workmate … pretty crude, but they’re sturdy.

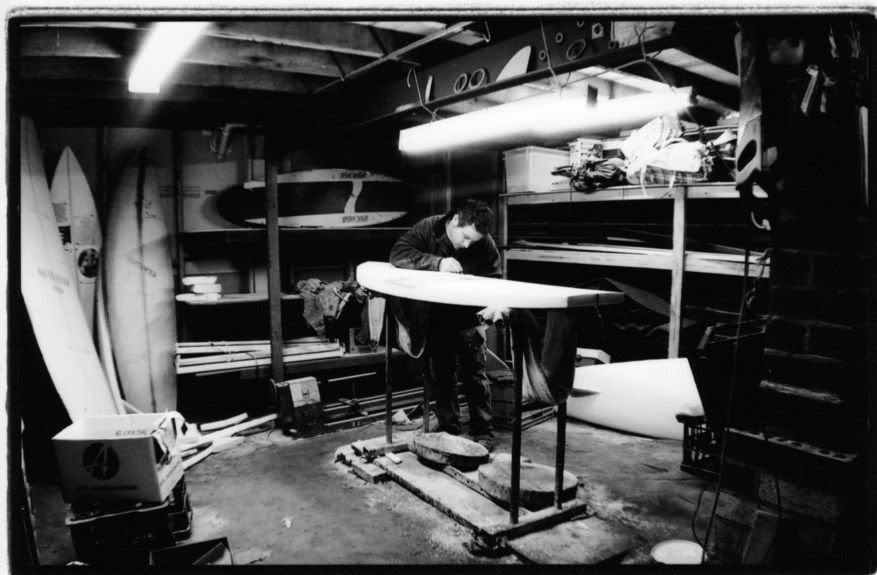

Old storage racks, converted to dexter’s laboratory spec…

lucky man.

I’m going to take Bud808’s basic stand design and sink 4" PVC sleeves into the cement, then carefully sand the 4x4 (actually scabbed 2x4’s) to fit tight so the uprights can be removed for storage…

Bud’s design - http://www.swaylocks.com/forum/gforum.cgi?post=269880;search_string=bud808;#269880

Gonna make them tomorrow. Total cost of materials for me was $20 + some scrap ply for the bucket bases.

Stoked on this thread!!! A big thanks Bud for his dims!!!

cpktoes…still think i like your idea out of any idea ive ever seen…havent figured out whether i want to cut that weight bench up or buy the square tubing…

i should take some pics of why the weight bench would provide lots of allready finished work, and i dont think the thing cost that much maybe 100-200 with weights and bars and all that, im guessing just the steel in yours would be pushing 100 bucks, plus the work of making it adjustable and what not…

what are you shaping anyway, i dont see any white dust… maybe its just the pics but it looks like brown dust… shaping wood?

Onion,

I cleaned out the room to install the new racks. Since then I have only been able to shape one board and cut out some templates I have been meaning to make lately. I think the brown dust is from the masonite. Can’t wait to fill it back up with the white stuff though. Oh, and thanks fot the comment on the racks. If I remeber right the materials cost about $80. Tubing was the majority. I used to work at Foam EZ though. Their racks are solid and at a reasonable price for a good finished product.

I knew a guy in CA called the onion, had a cool logo of the smiling onion with sunglassees. That you?

Mine’s adjustable and knocks down with wingnuts for easy storage. A necessity for me since I have to put two cars in my garage.

I like Cross300’s. Clever use of the Black & Decker Workmate.

Here is a pic of my stands just after concrete pour. The 4" PVC pipe in cement worked great, just took a little while to shave down the 4x4 (scabbed) to fit.

Thanks to everyone for the ideas!

yeah making templates will dirty up the area and any tools with brown for a while…

no im not the onion you’re thinking of, i thinnk i was just looking around the room when i needed a name and saw some onion dip… so that made my name…

but yeah im really set on that idea there… still havent found a weight bench to replace mine for a decent price so i might just get the steel and start welding…dont want to ruin mine without a replacement…

foam ez’s look good and im sure they are, but i like the single post design, plus id rather spend $80 and do some work, than spend 300 for a pre made rack…

if i was that sort of person id be buying boards not building them…haha…

any idea how deep and wide the slot is for your board on rail?.. my racks felt shallow at some points in shaping…

Onion,

I went 12 in tall on the “U” and I think 6 in wide. It left plenty of room for a board to lay on its side and plenty of adjustment room for setting the carpet in there. Only drawback is there is a little flex with being that tall. Maybe 10 in is better?

thanks ill have to measure my ones i use now… i know they’re less than 6" wide, and likely about 9-10" deep… its probably the narrow width thats gives me the problems…the board on rail wants to flip from one side to the other too eaisly, i definately need to make the new ones wider in the U…

too deep though is likely better than too shallow, i might try 12"deep also …and if its too deep for my liking , then thats eaiser to fix than if i make them too shallow…

ill post mine when i ever get them done… every time i have the chance to work on new racks the rest of the house is asleep… the grinder and whatnot get pretty loud…guess i could do it at the shop, but the garage is better for this sort of thing. grinding, cutting, welding steel dont mix too well with boards and resin, acetone, etc…

is necessity the mother of invention or am i a lazy tightwad?

(works though!)

4" wide x 5/16" thick bent steel plate done pro by a friend of my dad’s. I drew up the bends as a go by, I took the idea from a picture I saw of Matt Kechle’s(sp?) stands. The uprights are screw jacks for adjustable height, welded to 3/8" steel plate (approx. 24" x 24") so there isn’t any cord hangup. My buddy bolted 'em to the floor, but it’s really not necessary as the plate is plenty heavy and stable by itself. I wrapped it in foam rubber and wrapped that in that rubberized shelf liner stuff you can buy at the supermarket. Super no-skid and non-abrasive.

Here are my cheap convertibles

7/10