ok

I will bite

that guitar is nice, looks like a Les Paul custom, nice wood

what year?

ok

I will bite

that guitar is nice, looks like a Les Paul custom, nice wood

what year?

re: bubble

bag attachment

quantity of resin used in lam

hand smoothing the bag as it reaches vacuum

breather

re: bubble

Attach the hose to the other side of the bag. Wet epoxy on top, Vacuum hose on bottom. Also keeps epoxy from getting sucked into the hose and pump.

Damn your clever!

yup = )

llilibel03,

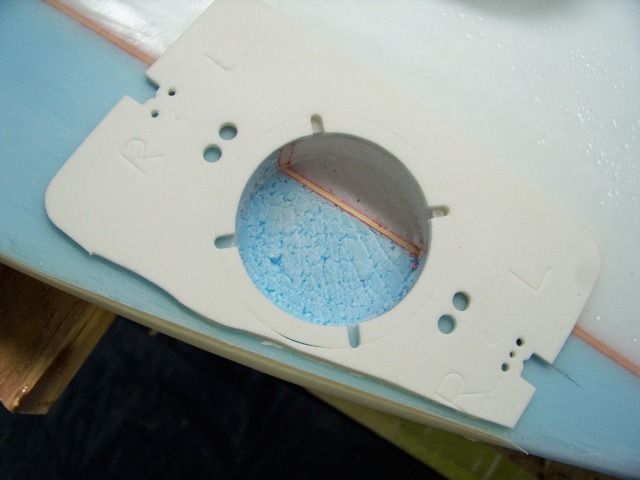

This is what I use to prevent the “bubble” if I need to place my vacuum port over the laminate.

Those are made out of PVC foam and the base ( thinner yellow piece) is beveled. Put breather under and between then.

[img_assist|nid=1067407|title=vacuum port base 1|desc=|link=none|align=left|width=640|height=360]

[img_assist|nid=1067408|title=vacuum port base 2|desc=|link=none|align=left|width=640|height=360]

OK. It’s been awhile. I’ve been mostly sanding. I have to do everything by hand, flat block and flat block with foam backing because I build in our condo. RIght under our window is a jacuzzi. If I have the exhaust fan on and use a disc sander, wonderful clouds of white dust float out over anyone in the jacuzzi. Not good (unless there is someone I really detest, then I figure I could start foiling some fiberglass fins).

Here’s some photos of 4wfs install. I really like this system. Note that my install is not according to their instructions. I used a hole saw where they recommend a router. I used a router to clean out the foam so I could have just used a router period, but routers make me nervous.

I scratched up the XPS really good before installing

One note- when cutting the fiberglass to line the hole, make it extra large. The one area you see where it was kind of short (the left side of the box), I kept getting resin spilling over the lip into the cup. Where the glass was cut long, I could just fold back the glass to the foam masking. The install went fine but I forgot to put in white pigment (I was touching up an area of the resin dam on the rail).

So one board is finished-

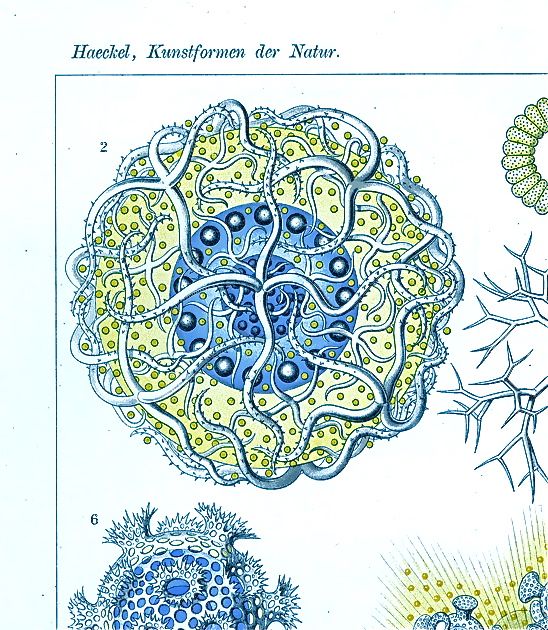

I cannot claim responsability for the laminates. The art is from an 19th century German physician turned naturalist. He did these sudies/prints of various marine life and these were jellyfish. He calls them “Medusa.” In Italy they call jellyfish “medusa” also. I looked up the mythology of the Medusa. Everyone knows the part about the lady with snake hair, but after Perseus cut it off he gave it to Athena who used it on her shield as an evil averting device. So I thought of it as an evil averting device. Besides they look cool. I doctored the images in iphoto to get the color to match the blue foam.

Of course the evil averting part didn’t work against my stupidity. After I shot the photos I had the board leaning up against a wall, while I started to put away rolls of cloth etc. I hear this sliding sound and looked up just in time to see the nose of the board crash against the wall. Now I know these boards are NOT ding proof. Put this photo in the idiot file. DUH. Have you ever dung a board before it even hit the water???

Meanwhile the twinzer is in the finning stage.

First the FCS for the canards and trailer-

I’m a bit worried about the canard plugs. I set them at the Jobson standard 10 degrees and they look kind of tweaked. Like I’m not sure when I grind them if the outside edge will be above the deck or, if the inside will get ground down so much that there will not be a grub hole left.

I rough ground them and now have the proboxes setting.

Down the home stretch.

I’ve got to get these done soon as the wife and daughter are coming home Thursday and they expect me to be working on my paintings…

Good Job Jeff!

Really nice lookin board, looks like Twinzer will be a winner too!

Like the use of the graphics down the middle of the board, nice and simple but effective, I got the same book, thought i recognised them:)

fricken bitchen,,, nice work!

Thanks for the nice words. Work continues…

“Pendo” time. I did this once before on a board that only lasted 3 surfs. I loved it . Thing is I don’t really remember how I did it. So it was like doing it for the first time again

First, the material had one side that is textured and shiney. I tried different tools to sand it flat but only the grinder worked. I was worried that the pieces will not be very flat.

Rough cut with scissors-

2 pieces stacked on the board-

Sprayed both sides with Super 77 and put them in the bag for about 40 minutes-

Out of the bag. It seemed some of the edges didn’t adhere but I’m thinking it was the overlap on the tape-

Now comes the hard part. Shaping this stuff with the grinder.

First two passes with the grinder-

[IMG]http://i140.photobucket.com/albums/r31/llilibel03/2passes.jpg[/IMG]

I soon discovered that when your grinder first hits the foam it grabs and gouges. It didn't happen on those first passes on the edges, but as soon I started working on the flatter areas I started making a real mess. I found that slowing the speed almost made this effect worse. I was butchering the stuff-

[IMG]http://i140.photobucket.com/albums/r31/llilibel03/waveycut.jpg[/IMG]

Also, when the grinder hit the edge of the second piece spinning the "wrong" direction it peeled up the foam. I made a few big mistakes doing that -

[IMG]http://i140.photobucket.com/albums/r31/llilibel03/wrongwaycut.jpg[/IMG]

Judging from my laminate line I was doing a horrendous job-

[IMG]http://i140.photobucket.com/albums/r31/llilibel03/badshape.jpg[/IMG]

Also this stuff makes a mess. There was black dust everywhere, in my resin mixing cups, on the vertical surfaces of the walls, everywhere..

[IMG]http://i140.photobucket.com/albums/r31/llilibel03/mess.jpg[/IMG]

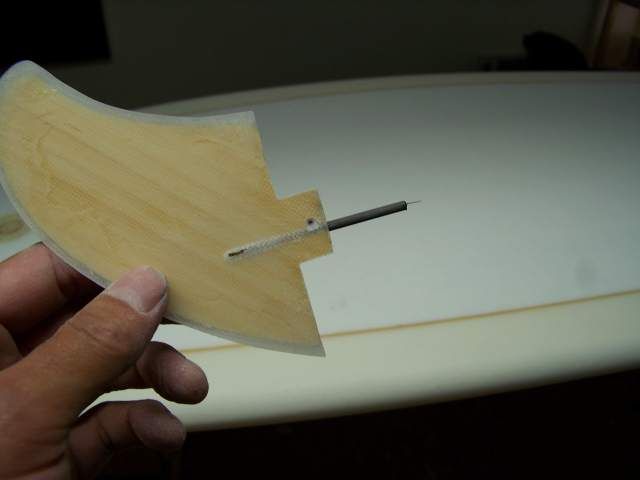

In the meatime work progresses on the twinzer fins-

I really don’t like foiling fins (no offense Chip!). Maybe because I always end up doing it at the end of a build when I’m pretty tired. Also, bamboo is a bitch because there are no layer lines to help you with the foil. You have to constantly move it under the lights to see what you’re doing. I find the rasp is the best, quickest tool for foiling bamboo (after getting the rough shape with a grinder).

Foiled-

Notice the two different cant angles- 10 for the canard, 4 for the main fin, but when I tighten the screws they go to like 4 and 0. I gotta figure that one out.

They’ve been glassed and I’m waiting for the hot coat to set. Meanwhile here’s a photo of my carbon rod reinforcement for the FCS fin-

I gotta get me some bamboo,

fins made from that look so niiice

how many layers of cloth did you use , and on the tabs , too ?

do the tabs fit really snug ? [because I have found sometimes you can get a few extra degrees cant if they are too THIN [but also risk breaking the fin too ]

p.s. - I HATE foiling too ...don't let people fool you , it is one of the hardest things to do ...I am no master , yet ...

cheers

ben

Cool fins how much glass did you put on them?

Flying through these builds very interesting thread.

Keep seeing bamboo chopping boards at the hardware store probably thick enough for two panels and cheap.

This is a fantastic thread. Thanks for sharing Jeff!

Beautiful work Jeff! I love seeing your annual shapes and am very interested in the ride report. Hopefully we’ll back down your way in the next week or two. Maybe hookup for a surf and get the kids together?

Thanks everyone. Senor, give us a ring. S + I are in Italy right now. S is miserable. It’s hot and humid and she’s suffering some kind of heat rash, not having fun at all. I, on the other hand, have been doing what I love to do- surf and make surfboards.

Before I get to pics, to answer questions- the fins are 2 layers of 4 oz s glass on each side. In the past I have made the tabs too thick and then I had to do a whole other step- grinding down and then adding glass again. This time I erred on the side of thin. So they fit easily in the boxes, but when I tightened them they lost cant. It was an easy fix- I just added a little strip of wood on the bottom of the tab, railside. Now cant is all good.

I always put 1/8" carbon rod in the FCS tabs. I’m 50/50 as far as drilling them straight. As you can see in the earlier photo that one went in crooked. I just added another patch on glass over it. The other one went straight and was not visible.

So here’s the twinzer. I’m kind of excited about this one- more of a groveler, perfect for now, I hope. 6-0 x 20-1/4 x 2-3/8. I should mention that both boards without fins came in just under 6 pounds. Not super light, but light enough.

Another Medusa by the German artist-

Time to wax em up!

BEAUTIFUL !

love it !

how is the surf in italy , at the moment ??

will you do a RIDE REPORT , please , mate ?

cheers

ben

Wow, that one is beautiful!

"....It's hot and humid and she's suffering some kind of "heat rash," * not having fun at all.....

I, on the other hand, have been doing what I love to do- surf and make surfboards ...."

...or maybe you need to do your fibreglass sanding OUTSIDE the hotel bedroom ???

* " heat rash" , or ???

I had a friend stay over one night , a WEEK after I had been sanding a board . [Yes , I had vaccuumed etc thoroughly .]

she woke up the next morning , with rashes ALL over her body .....

dot dot dot

[edit :

for those 'wondering' ...

I was COMPLETELY rash-FREE ! ]

..she wasn't such a 'special friend' after THAT , I can tell you ...she wasn't impressed at all !

..... she was obviously not a surfer , unfortunately .....]

wow

I realy like that last one llilibel

realy sharp

fricken nice,,,, top notch!